Metal Laser Cutting Machine

Release time:

2025-07-10

Author:

Source:

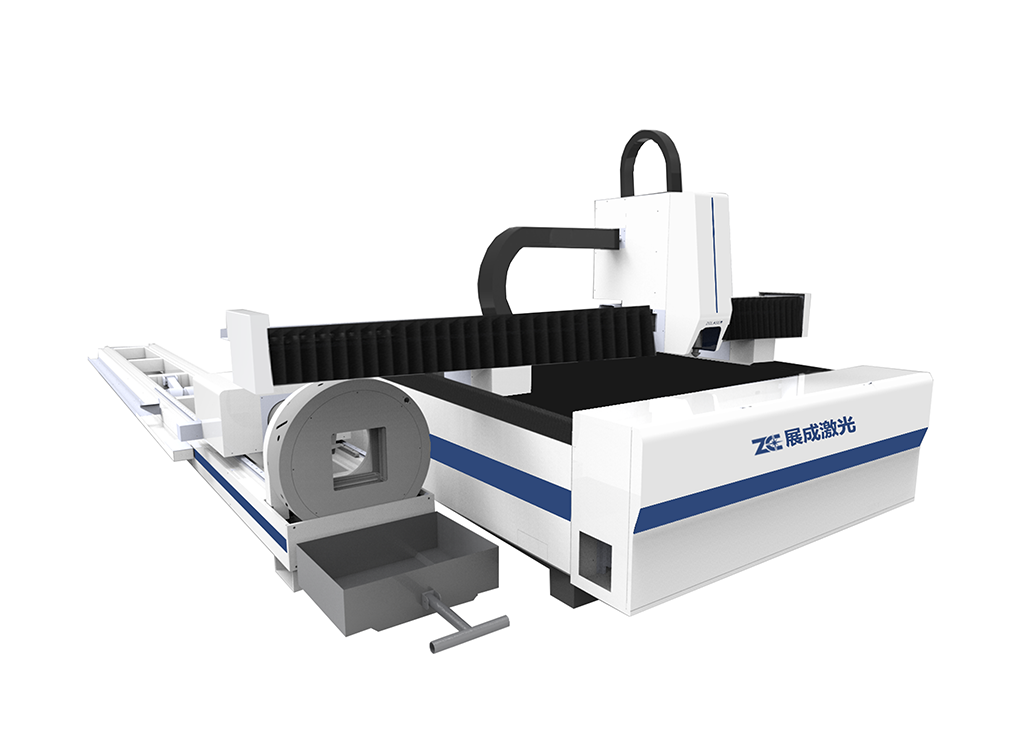

metal laser cutting machine

In the fast-evolving world of metal fabrication, the metal laser cutting machine stands as a cornerstone of precision and efficiency. This technology has dramatically transformed how industries approach metal cutting, providing a blend of speed, accuracy, and versatility that traditional methods simply cannot match. As the demand for high-quality metal products increases, the reliance on laser technology grows, underscoring its role in modern manufacturing. In this article, we'll explore the ins and outs of metal laser cutting machines, focusing on their importance in industrial applications, and examine how they have become integral to the industry's growth.

What is a Metal Laser Cutting Machine?

A metal laser cutting machine uses a high-powered laser beam to cut through various types of metal. The laser beam melts, burns, or vaporizes the material, leaving behind a high-quality finish and precise edges. This process is controlled by computer numerical control (CNC) systems, ensuring accuracy and repeatability. The integration of CNC technology allows for seamless operation, offering manufacturers the ability to execute intricate designs with minimal human intervention. The result is a significant reduction in errors and wastage, contributing to a more streamlined production process.

Types of Metal Laser Cutting Machines

- Fiber Laser Metal Cutting Machine: Known for its efficiency and precision, the fiber laser metal cutting machine uses optical fibers to transmit the laser. It's ideal for cutting thin to medium-thick metals and is valued for its low maintenance costs and high cutting speed. The technology behind fiber lasers enables them to deliver high power density, which is crucial for achieving fast cutting speeds and fine detailing. Additionally, their compact design and energy efficiency make them a popular choice in industries looking to optimize space and reduce operational costs.

- CO2 Laser Cutting Machine: This type uses a gas mixture to produce the laser beam. It's versatile and can handle a wide range of materials, including thicker metals. However, it requires more maintenance compared to fiber lasers. The CO2 laser's ability to cut through non-metal materials like wood and acrylic adds to its versatility, making it suitable for diverse applications beyond metal fabrication. Despite the higher maintenance, its adaptability in handling various materials ensures it remains a staple in many manufacturing settings.

- Fibre Laser Cutting Machine: Similar to fiber lasers, these machines are particularly effective for cutting reflective metals and offer high efficiency with lower power consumption. Their ability to handle reflective materials like aluminum and copper without the risk of beam reflection damage makes them indispensable in industries where such metals are prevalent. The cost savings from reduced energy consumption and minimal maintenance further enhance their appeal to manufacturers aiming to balance performance with economic feasibility.

Advantages of Metal Laser Cutting Machines

The adoption of metal laser cutting machines has brought numerous benefits to the manufacturing industry. Here are some key advantages:

Precision and Accuracy

Laser cutting machines provide unmatched precision, capable of cutting complex shapes with minimal waste. The CNC technology ensures that cuts are consistently accurate, reducing the need for post-processing. This precision translates into high-quality products that meet stringent specifications, crucial for industries where detail and accuracy are paramount. Additionally, the ability to replicate designs with exactness facilitates large-scale production runs, ensuring consistency across all units.

Speed and Efficiency

Compared to traditional cutting methods, metal laser cutting machines operate at higher speeds, allowing for quicker project completion. This efficiency translates to increased production rates and reduced lead times. The rapid processing times not only boost manufacturing throughput but also enhance the ability to meet tight deadlines and adapt to changing market demands. The speed of laser cutting also allows for quick prototyping and testing, enabling faster innovation cycles within the industry.

Versatility

These machines can cut a wide range of metals, from steel and aluminum to copper and brass. This versatility makes them suitable for various applications, from automotive and aerospace to electronics and construction. The ability to process different materials without the need for frequent machine adjustments increases operational flexibility and reduces downtime. This adaptability is essential for manufacturers who need to switch between different projects and materials seamlessly.

Cost-Effectiveness

While the initial investment in a metal laser cutting machine might be significant, the long-term savings are substantial. The reduction in material waste, lower maintenance costs, and increased production efficiency all contribute to a lower overall cost of ownership. The precision and accuracy of laser cutting minimize the need for rework, further driving down production costs. Over time, the return on investment becomes evident as companies experience reduced operational expenses and enhanced product quality.

Applications of Metal Laser Cutting Machines

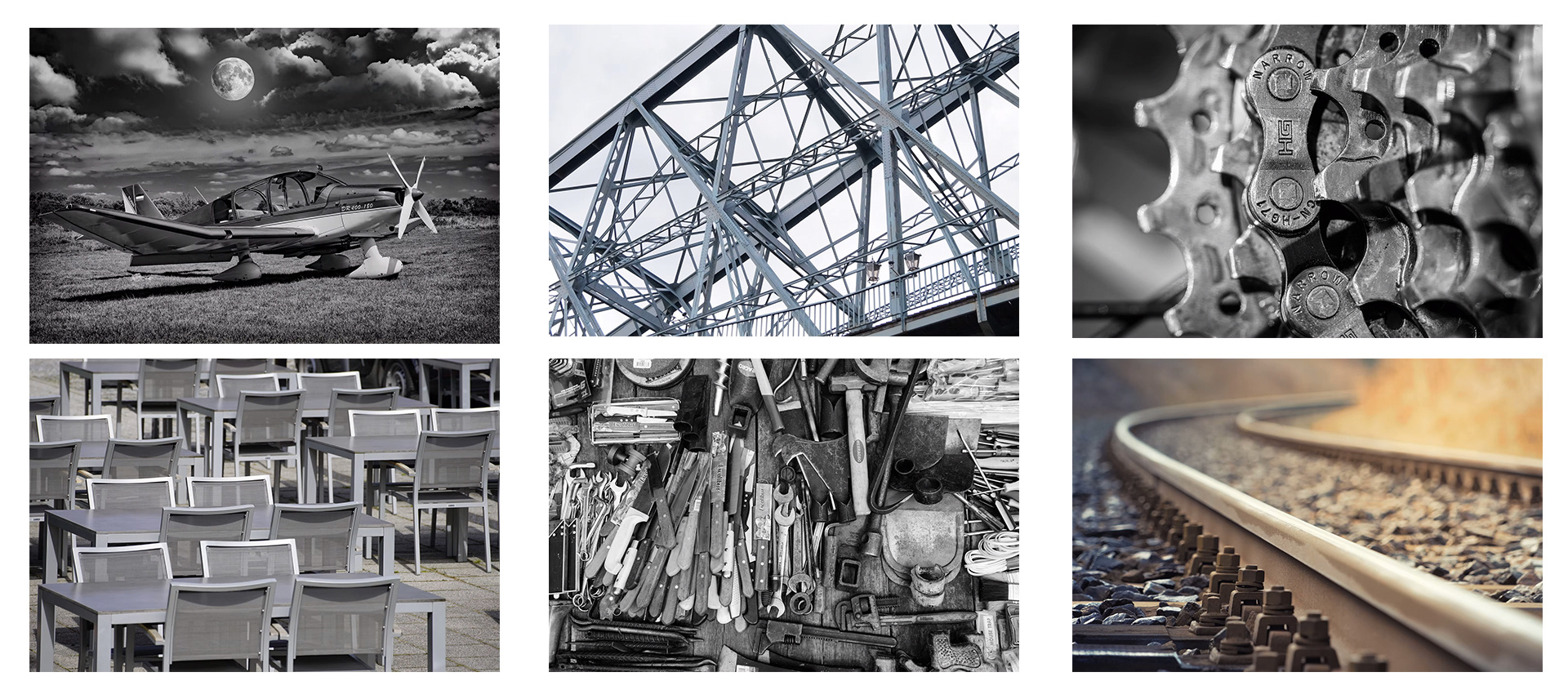

Automotive Industry

In the automotive sector, precision and speed are paramount. Metal laser cutting machines are used to produce intricate parts with tight tolerances, ensuring that vehicles meet safety and performance standards. The ability to quickly and accurately produce components such as gears, brackets, and panels enhances the efficiency of the automotive supply chain. As the industry moves towards electric and autonomous vehicles, the demand for precision parts is expected to grow, further solidifying the role of laser cutting technology.

Aerospace Industry

The aerospace industry demands high-quality components with exacting specifications. Laser cutting machines provide the precision needed to manufacture parts that can withstand extreme conditions. The technology enables the production of lightweight yet robust components, essential for the aerospace sector's focus on fuel efficiency and performance. From engine parts to structural components, laser cutting ensures that each piece meets the high standards required for aerospace applications.

Electronics and Electrical Industry

In electronics, components require precise and clean cuts to function correctly. Metal laser cutting machines are ideal for creating the delicate structures needed in circuit boards and connectors. The precision of laser cutting supports the miniaturization trend in electronics, allowing for the production of smaller, more efficient components. This capability is crucial as the industry continues to innovate and develop more compact and powerful electronic devices.

Construction and Architecture

For construction and architectural projects, laser cutters are used to create custom metal designs, from structural components to decorative elements. The ability to cut complex shapes easily makes these machines invaluable in this field. The precision and versatility of laser cutting enable architects and builders to realize intricate designs that enhance the aesthetic and functional value of buildings. As sustainable and innovative building practices gain traction, the demand for custom metalwork is likely to increase.

Choosing the Right Metal Laser Cutting Machine

When selecting a metal laser cutting machine, several factors should be considered:

- Material Type and Thickness: Different machines handle various materials and thicknesses. Ensure the machine you choose can handle the metals you'll be working with. Understanding the specific requirements of your projects will help in selecting a machine that provides optimal performance without compromising quality.

- Power Requirements: Machines come with different power ratings. Higher power machines can cut thicker materials but may consume more energy. Balancing power needs with energy efficiency is crucial for maintaining sustainable operations while meeting production goals.

- Cutting Speed: Consider the production speed you require. Faster machines can increase throughput but may come at a higher cost. Evaluating the trade-off between speed and cost will help determine the best machine for your business needs.

- Budget: While it's important to consider the initial investment, also think about long-term costs, including maintenance and operation. A comprehensive cost analysis will ensure that you make an informed decision that aligns with both your immediate and future business objectives.

The Future of Metal Laser Cutting

As technology advances, metal laser cutting machines continue to evolve. Innovations such as improved laser sources, automation, and AI integration are on the horizon, promising even greater efficiency and precision. These advancements will make laser cutting technology more accessible to a wider range of industries and applications. The integration of AI and machine learning could lead to smarter systems capable of self-adjusting for optimal performance, further reducing human intervention and error. As industries become more digitalized, the role of laser cutting will expand, driving new possibilities in manufacturing and design.

Conclusion

Metal laser cutting machines have revolutionized the metal fabrication industry by offering precision, speed, and versatility. Whether you're in automotive, aerospace, electronics, or construction, these machines provide the capabilities needed to meet modern manufacturing demands. As technology progresses, the future of metal laser cutting promises even more exciting developments, ensuring that this technology remains at the forefront of industrial innovation. Embracing these advancements will not only enhance production capabilities but also pave the way for new applications and opportunities across various sectors.

Key words:

industrial metal laser cutting machine,fiber laser metal cutting,metal laser machine,metal laser cutting machine,fiber laser cutting machine,laser cutting machine for sheet, laser cutter machine for metal,sheet metal laser cutting equipment,laser cutting machine for sheet metal,fiber laser cnc,laser steel cutting machine,fibre laser cutting machine,laser cutter for sheet metal

Floor 16, Building A, Rongsheng Times International, Licheng District, Jinan City, Shandong Province,China