What is a laser welding machine?

Release time:

2025-07-09

Author:

Source:

Discover how a welder with laser technology revolutionizes metal joining with precision and speed. Ideal for industries and hobbyists, explore versatile handheld and portable laser welders for efficient, clean welds.

welder with laser

Laser welding is revolutionizing the way we join metals. It's precise, efficient, and versatile.

A welder with laser technology offers unmatched accuracy and speed. This makes it a preferred choice in many industries.

From automotive to aerospace, laser welders are in high demand. They provide clean, strong welds with minimal post-processing.

Handheld and portable options add flexibility to the mix. These machines are perfect for on-site repairs and intricate tasks.

Whether you're a professional or a hobbyist, understanding laser welders is crucial. This guide will explore their types, benefits, and applications.

What Is a Welder with Laser?

A welder with laser technology uses focused light to join materials. It creates precise and high-quality welds.

Unlike traditional welding, laser welding is non-contact. This means no physical contact with the material, reducing wear on the equipment.

The benefits of a welder with laser include:

• Precision and accuracy in welds

• Fast processing speeds

• Minimal heat distortion

• Ability to weld dissimilar materials

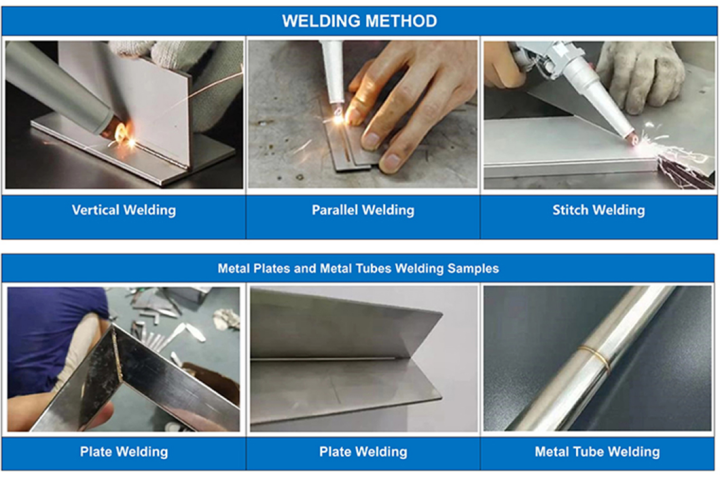

Laser welders are highly versatile and can handle a wide range of metals and thicknesses. They are used in various industries for their flexibility and efficiency. These welders are crucial in manufacturing settings where quality and speed are imperative.

Types of Laser Welding Machines

Laser welding machines come in various types, each designed for different needs and applications. These machines cater to both industrial and small-scale projects.

Common types include handheld laser welders and stationary models. Handheld welders provide flexibility and mobility, ideal for on-site tasks. Stationary machines are used in manufacturing environments for high-volume production.

Fiber laser welding machines are popular for their efficiency and speed. They use fiber optics to deliver high-quality welds with minimal energy consumption. Another type is the solid-state laser, which is favored for its precision and consistency across materials.

Here's a quick overview of laser welding machine types:

• Fiber laser welders

• Solid-state laser welders

• CO2 laser welding machines

Understanding the types of laser welding machines aids in selecting the right one for specific tasks. Whether for small projects or industrial use, there's a suitable laser welding machine available.

Key Benefits of Laser Welding

Laser welding offers numerous advantages over traditional welding methods. These benefits make it a preferred choice across various industries.

One significant advantage is precision. Laser welds are incredibly accurate, producing clean and small joints. This reduces the need for extensive post-weld cleaning and finishing.

Additionally, laser welding is efficient and fast. It provides high-speed processing, which increases productivity and reduces labor costs. Moreover, lasers can weld a wide range of materials and thicknesses, enhancing versatility.

Key benefits of laser welding include:

• Precision and accuracy

• Speed and efficiency

• Versatility across materials

• Minimal thermal distortion

These benefits make laser welding machines a valuable investment. Their ability to produce strong, precise welds is unmatched in the industry.

Applications of Laser Welders

Laser welders find extensive use in diverse industries, thanks to their high precision and efficiency. They are not just limited to industrial settings but have broader applications.

In the automotive industry, laser welders are used for welding car parts. Their precision ensures safety and durability in vehicle manufacturing. Aerospace companies also rely on laser welding for assembling lightweight aircraft components.

Beyond industrial uses, laser welders are used in electronics. They create delicate joints necessary for small components like circuit boards and sensors.

Applications of laser welders include:

• Automotive manufacturing

• Aerospace engineering

• Electronics assembly

These versatile tools help ensure quality and performance across various sectors.

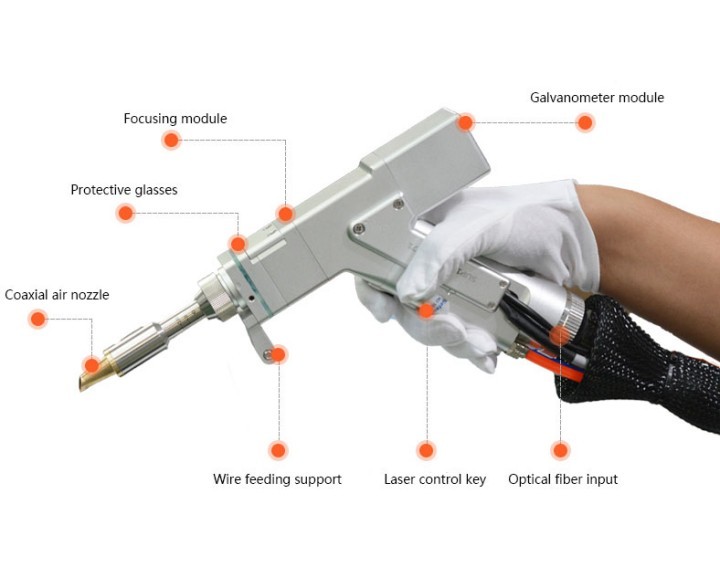

Handheld and Portable Laser Welders

Handheld and portable laser welders are gaining popularity due to their mobility and ease of use. These machines provide flexibility for on-site repairs and are suitable for both professionals and hobbyists.

The key advantage of handheld laser welders is their ability to perform tasks in tight or hard-to-reach areas. This makes them ideal for maintenance work on machinery or equipment without dismantling parts. Their compact design allows users to transport them easily between job sites.

Common features of these welders include:

• Lightweight and portable design

• User-friendly interface

• Versatility across various materials

Considering their benefits, handheld and portable laser welders stand out as practical tools for multiple welding tasks.

How to Choose the Best Laser Welding Machine

Selecting the right laser welding machine involves evaluating several factors. Begin by considering the types of materials you plan to weld. Different machines are better suited for particular metals like aluminum, steel, or titanium.

Another critical factor is the power output of the laser. More powerful machines, like a 1500w laser welding machine, can handle thicker materials but might be unnecessary for smaller projects.

Cost is also a vital consideration, as prices vary widely based on features and capabilities. Consider these aspects:

• Project size and scope

• Material compatibility

• Power requirements

• Budget constraints

By assessing your specific needs, you can find the best laser welding machine for your projects.

Laser Welder Cost and Pricing Factors

The cost of laser welders can be a significant investment. Prices can vary greatly, influenced by several factors such as the machine's power, brand, and included features.

When budgeting for a laser welder, consider the following pricing factors:

• Power Output: Higher power levels often increase cost.

• Brand Reputation: Renowned brands may charge a premium for quality assurance.

• Additional Features: Advanced features and capabilities can drive up prices.

• Warranty and Support: Machines with longer warranties might cost more but offer peace of mind.

Understanding these factors can help you make an informed decision based on your financial plans and project needs.

Safety and Training for Laser Welding

Laser welding requires strict adherence to safety protocols. Proper training is crucial to ensure safe operation and protect operators from potential hazards.

Important safety measures include:

• Protective Gear: Use of safety goggles and gloves.

• Ventilation: Ensure adequate ventilation to remove fumes.

• Training: Comprehensive training on machine operation and maintenance.

Implementing these practices helps maintain a safe work environment and enhances operator competence.

Frequently Asked Questions about Laser Welders

Laser welders are sophisticated tools, and naturally, users have many questions. Below are some common inquiries:

• What materials can laser welders handle? They are versatile and can weld metals like steel and aluminum.

• Do laser welders require frequent maintenance? Regular maintenance is essential to ensure optimal performance and longevity.

Understanding these aspects can guide potential users in making informed decisions.

Conclusion: Is a Welder with Laser Right for You?

A welder with laser technology offers precision and efficiency beyond traditional methods. Whether you're a professional or hobbyist, these machines can enhance productivity and quality.

Before investing, consider your specific needs and budget. Compare features across models to find the best fit. Laser welding can transform your projects, from intricate designs to industrial tasks. If precision and speed are priorities, this technology is worth exploring.

Key words:

handheld laser welding machine,laser welding machines for sale,handheld laser machine,hand held laser welders,laser welders for sale,small laser welding machine,laser welding equipment,handheld fiber laser welding machine,laser welding machine,portable laser welding machine,laser welders,portable laser welder,welder with laser,cheap laser welder,small handheld laser welding machine price,handheld laser welder,laser welding device,laser welding and cutting machine,handheld laser welding machine price,laser weld cutter,how much are laser welders,laser welding gun,best laser welding machine,mini laser welding machine,handheld fiber laser welder,fiber optic laser welding,1500w laser welding machine,best laser welders,laser welding mini,laser welder cost

Next:

Floor 16, Building A, Rongsheng Times International, Licheng District, Jinan City, Shandong Province,China