Top Laser Cutter for Metal: Precision & Efficiency

Release time:

2025-07-29

Author:

Source:

Discover the precision and efficiency of a laser cutter for metal, ideal for diverse metalworking tasks. Explore types, benefits, and applications.

laser cutter for metal

Laser cutters for metal are revolutionizing the metalworking industry. They offer precision and efficiency unmatched by traditional methods.

These machines use a focused laser beam to cut through metal with ease. This technology is ideal for both small-scale and large-scale production.

Manufacturers and hobbyists alike are turning to laser cutters for their versatility. They can handle a variety of metals, from steel to aluminum.

Choosing the right laser cutter involves understanding your specific needs. Factors like material type and production volume play a crucial role.

In this guide, we'll explore the types, benefits, and applications of laser cutters for metal.

What Is a Laser Cutter for Metal?

A laser cutter for metal is a machine designed to precisely cut metal sheets. It uses a high-powered laser beam to make accurate cuts. This tool is invaluable in industries requiring detailed metalwork.

The process begins by directing a focused laser beam onto the metal surface. The laser heats the metal to a point where it melts or vaporizes, creating a clean cut. The precision of the laser allows for intricate designs and minimal waste.

These machines are essential in manufacturing settings. They provide high speed and accuracy without direct contact with the material. This reduces the risk of distortion during cutting.

Key characteristics of a laser cutter for metal include:

- High precision and accuracy

- Ability to cut various metals

- Non-contact cutting process

- Minimal waste production

Understanding how these machines operate can help in choosing the right type for your application. Advanced laser cutters are also equipped with software for optimal performance.

Types of Metal Laser Cutting Machines

Metal laser cutting machines come in different types, each suited for specific tasks. The main types include fiber laser, CO2 laser, and crystal laser machines. Each has unique features and applications.

Fiber laser cutters are popular for their efficiency and adaptability. They use optical fibers to amplify the laser and are perfect for cutting thin metal sheets. Their speed and precision make them ideal for intricate patterns.

CO2 laser machines are traditional yet effective. They are versatile and can cut metals and non-metal materials. Despite their older technology, they're known for handling thicker metals well.

Crystal laser machines are less common but highly effective. They are used for specialized applications requiring extreme precision. Their high cost often limits them to niche markets.

In summary, key types include:

- Fiber lasers: High efficiency, ideal for thin metals

- CO2 lasers: Versatile, handles thicker metals

- Crystal lasers: Specialized, very precise

Choosing the right type depends on the material, thickness, and specific requirements of your project.

CO2 vs. Fiber Laser Cutters

Choosing between CO2 and fiber laser cutters depends on your needs. CO2 lasers have been around longer and are known for their versatility. They effectively cut metals and organic materials, such as wood.

Fiber lasers, on the other hand, excel in speed and precision. They are ideal for cutting metals, especially reflective ones like copper and brass. Their low maintenance and energy efficiency add to their appeal.

The decision hinges on material types and usage frequency. For example, if you work with diverse materials, a CO2 laser's versatility is valuable. However, if metalwork is your sole focus, fiber lasers offer superior performance.

Consider the following when choosing:

- Material type: metals vs. mixed materials

- Frequency of use: occasional vs. continuous

- Budget constraints: initial investment vs. operational costs

Each type offers distinct advantages, making the choice dependent on specific cutting needs and budget considerations.

Key Features and Benefits

Metal laser cutters offer impressive precision and efficiency. They provide clean cuts with minimal material waste, which is essential in high-volume production. Their accuracy ensures high-quality finishes with little need for post-processing.

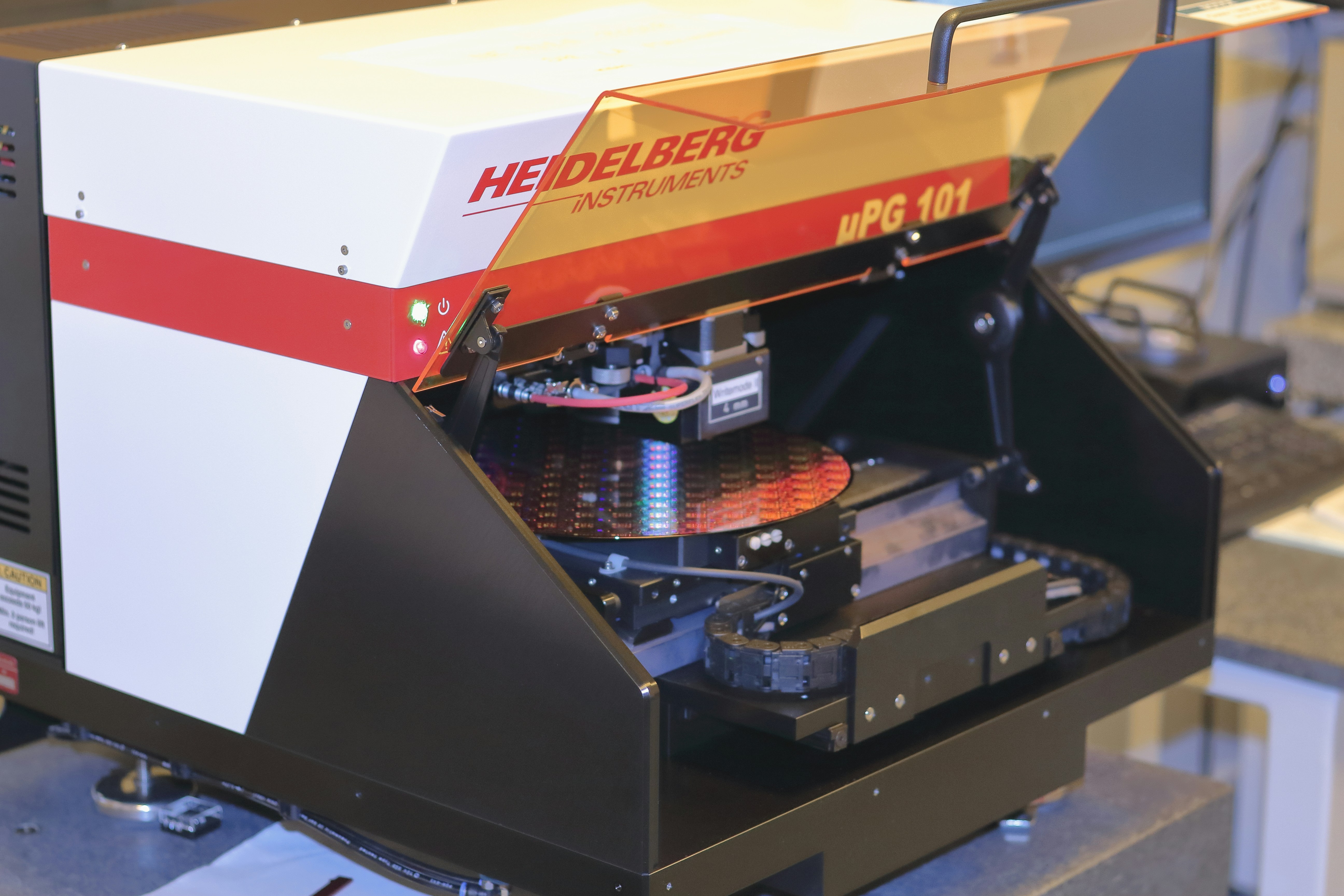

Automation is another significant advantage. CNC laser cutters for metal are programmable, enabling them to handle complex and repetitive tasks with consistency. This feature is crucial for large-scale manufacturing, where precision and speed are paramount.

Versatility is a key characteristic of these machines. They can cut various metals, from thin sheets of steel to thick aluminum slabs. Such adaptability makes them invaluable in industries like automotive, aerospace, and construction.

The cost-effectiveness of fiber laser cutting machines is also notable. Despite the initial investment, they offer long-term savings through reduced labor costs and increased throughput. Their durability means lower maintenance needs over time.

Key benefits include:

- Precision and minimal waste

- Automation and repeatability

- Versatility in material handling

- Cost-effectiveness and efficiency

Overall, these features make laser cutters a preferred choice for manufacturers seeking quality, speed, and economy in their operations.

Applications of Laser Cutters in Metalworking

Laser cutters are pivotal in many metalworking applications. Their precision and speed make them ideal for producing intricate parts and components. Industries like automotive and aerospace rely heavily on their capabilities for creating high-quality metal parts.

In fabrication, laser cutters handle tasks ranging from cutting and engraving to welding. They are adept at producing detailed designs that are difficult to achieve with traditional methods. This versatility allows manufacturers to push design boundaries and innovate.

Metal laser cutters also contribute significantly to the construction industry. They are used for precise cutting of structural elements, ensuring that components fit together seamlessly. This precision enhances the strength and durability of constructions.

Other notable applications include:

- Cutting decorative metalwork

- Creating prototypes for new designs

- Producing custom metal components

- Engraving logos or markings on metal surfaces

These diverse applications highlight the laser cutter's importance in modern manufacturing, offering both functional and aesthetic benefits.

How Does a Laser Cutter for Metal Work?

Laser cutters for metal utilize a high-powered laser beam to cut through metal. The process begins by generating the laser beam through a gain medium. This beam is then directed onto the metal surface using mirrors and lenses, focusing it to a very fine point.

When the laser hits the metal, it melts or vaporizes the material, creating a precise cut. The speed and accuracy of this process are controlled by CNC (Computer Numerical Control) systems. These systems enable intricate patterns and designs, which would be challenging to achieve manually.

A typical laser cutting process involves:

- Directing the laser onto the metal

- Focusing the beam to a specific point

- Melting or vaporizing the material

- Removing molten material with assist gases

These steps occur rapidly, allowing for efficient processing of various metal types and thicknesses.

Choosing the Right Laser Cutter for Metal

Selecting the right laser cutter for metal depends on several factors. It's essential to consider the types of metals you plan to work with. Each metal responds differently to laser cutting, affecting the machine's efficiency and performance.

The thickness of the metal is another critical factor. Different laser cutters are designed to handle varying thicknesses, impacting the cut quality and speed. Thus, understanding the thickness range is pivotal when choosing a machine.

Production volume also plays a role in the decision-making process. Higher production volumes require machines that offer faster cutting speeds and durability. For lower volumes, you might prioritize precision over speed.

Important considerations for choosing a metal laser cutter include:

- Type of metal

- Metal thickness

- Production volume

- Precision needs

- Budget constraints

Finally, your budget will heavily influence your choice. Balancing initial investment with long-term benefits can help ensure a wise purchase.

Maintenance and Safety Considerations

Maintenance is vital for the optimal functioning of a laser cutter for metal. Regular cleaning ensures that lenses and mirrors remain free from debris. Proper calibration is also necessary to maintain cutting precision and performance.

Safety cannot be overlooked in laser cutting operations. Machines often come with essential safety features like enclosures and fume extraction systems. These components help in protecting operators from harmful laser radiation and fumes.

Key maintenance and safety tips include:

- Routine cleaning and lens inspection

- Regular calibration checks

- Ensuring safety enclosures are intact

- Using proper ventilation systems

By adhering to these guidelines, you can maximize the lifespan of your equipment and enhance workplace safety.

Cost and ROI of Metal Laser Cutting Machines

The initial investment in metal laser cutters can be substantial. However, the long-term benefits often justify the cost. These machines offer enhanced efficiency, which translates to time and cost savings in production.

Consider these factors affecting ROI:

- Reduced material waste due to precise cutting

- Faster production times reducing lead time

- Lower labor costs with automation capabilities

Focusing on these elements can significantly improve the return on investment. By doing so, businesses can enhance their bottom line through efficient and precise metal cutting processes.

Future Trends in Metal Laser Cutting Technology

Metal laser cutting technology continues to advance, driven by innovation. New developments focus on increasing precision and cutting speed. These advancements aim to cater to the needs of diverse industries.

Integration with smart manufacturing processes is also on the rise. This integration includes the use of AI and IoT, enhancing automation and monitoring. These trends promise to boost efficiency and redefine possibilities in metalworking.

Conclusion

Laser cutters for metal have transformed the manufacturing industry. They offer unparalleled precision, efficiency, and versatility. As technology advances, these machines will continue to play a vital role.

Choosing the right laser cutter requires understanding specific needs and applications. With proper maintenance and safe usage, businesses can maximize their investment. The future looks bright for laser cutting technology.

Key words:

cnc fiber laser,laser cnc machine for metal,metal cutting laser cnc,fiber laser metal cutting,laser cutter for metal,industrial laser cutting machine,fiber laser cutting,fiber optic laser cutter,laser cutter for steel,table laser cutting machine,fiber optic laser cutting,cnc laser cutter for metal,fiber laser cutter for metal,metal cutting laser,cnc laser cutting machine,laser sheet metal cutter,fiber laser cutter,laser steel cutting machine,fibre laser cutting,laser cutter machine metal,cnc laser cutter for steel,laser metal cutting equipment,industrial laser cutter,metal laser cutting machine,cnc laser table,fiber laser cutting machine,cnc laser cutting,fibre laser cutter,sheet metal laser cutting equipment,cnc fiber laser cutting machine

Floor 16, Building A, Rongsheng Times International, Licheng District, Jinan City, Shandong Province,China