How to Adjust the Marking Depth in Laser Marking

Release time:

2025-09-26

Author:

Source:

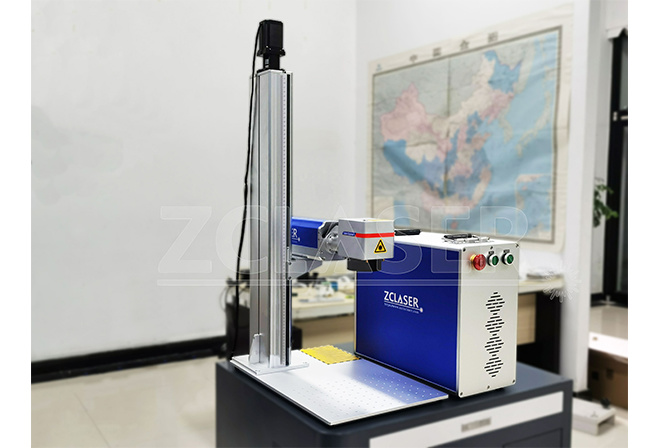

Laser marking machines have built‑in tools for adjusting the marking depth. To achieve accurate and precise marking depth on laser‑marked materials, certain key adjustments are required. Some of these adjustments are listed below.

Laser marking machines have built‑in tools for adjusting the marking depth. To achieve accurate and precise marking depth on laser‑marked materials, certain key adjustments are required. Some of these adjustments are listed below.

Laser Power Adjustment

To achieve a sharper, denser beam quality, you can increase the laser power and light source.

Laser Marking Speed

By adjusting the laser marking speed, you can achieve better results. Slower marking speeds produce denser marks, and vice versa.

Focal Length and Spot Size Visualization

Marking depth can be adjusted by properly adjusting the laser lens' focal length and spot size.

Using the Right Laser Accessories

Using the right laser accessories can improve productivity and allow you to adjust the marking depth for both metal and non-metal materials.

Challenges and Limitations of Laser Marking Depth Adjustment

While adjusting the marking depth with a laser marking machine has many benefits, it also presents some challenges and limitations. Therefore, we will discuss some of these valid points here.

Material Compatibility

Different materials react differently to laser marking, and adjusting the marking depth based on material composition can be challenging. Furthermore, some materials may absorb or reflect laser energy differently, making it difficult to achieve consistent and controllable marking depth across a wide range of materials.

Equipment Limitations

The laser marking equipment itself may have limitations in terms of power, focus, or control settings. These limitations may restrict the possible depth adjustment range or make fine-tuning the marking depth difficult.

Surface Variation

The material surface type may affect marking depth adjustment. Furthermore, uneven or curved surfaces may require additional adjustments to maintain a consistent marking depth. Ensuring uniform depth across irregular surfaces can be technically demanding.

Heat Distribution

Laser marking involves locally heating the material surface to create the desired mark. Adjusting the depth requires precise control of laser power and exposure time to avoid excessive heat buildup. Improper control can lead to unwanted thermal effects such as discoloration, melting, or damage to the material.

Cost Considerations

Implementing Laser Marking Depth Adjustment Specialized equipment or additional features may be required, increasing the overall cost of the marking system. It is important to weigh the benefits of depth control against the associated costs and determine the best balance for your specific application.

Key words:

laser marking machine

Floor 16, Building A, Rongsheng Times International, Licheng District, Jinan City, Shandong Province,China