machine

Key words:

X-Series Open-Frame Single-Platform Laser Cutting Machine

Focusing on the all-water-cooled design of the component, it delivers high power in a compact size—enabling long-lasting cutting without overheating or smoking, while also extending the lifespan of the cutting head.

ZCMini-HPT Automatic Platform Laser Welding Machine

1. Continuous Operation Capability: Supports 24/7 uninterrupted operation. 2. Process Optimization: Enables complex curved surface welding via six-axis robotic arms and intelligent path planning. 3. Data-Driven: Real-time collection of parameters like temperature and pressure enables predictive maintenance. 4. Stable Performance: Delivers reliable and consistent operation over extended periods. 5. Safety and Compliance: Zero-flux process achieves zero VOC emissions.

ZCGX-HPT Handheld Laser Marking Machine

All metals: gold, silver, titanium, copper, alloys, aluminum, steel, manganese steel, magnesium, zinc, stainless steel, carbon steel/low-carbon steel, various alloy steels, electrolytic plates, brass sheets, galvanized sheets, aluminum, diverse alloy plates, assorted metal sheets, rare metals, coated metals, anodized aluminum, and other specialized surface treatments—including oxygen-decomposition plating on aluminum-magnesium alloy surfaces.

Guide to Preventing Condensation and Maintaining Chillers

Laser equipment often encounters a problem during summer operation: condensation. Condensation refers to the phenomenon where, when the surrounding temperature drops below the “dew point temperature” of the environment, the moisture in the air gradually reaches saturation until water droplets form on the surface of objects. Condensation can cause the electronic and optical modules inside the laser to be corroded by moisture, leading to issues such as corrosion, short circuits, and malfunctions, which severely impact the performance and lifespan of the laser.

Key words:

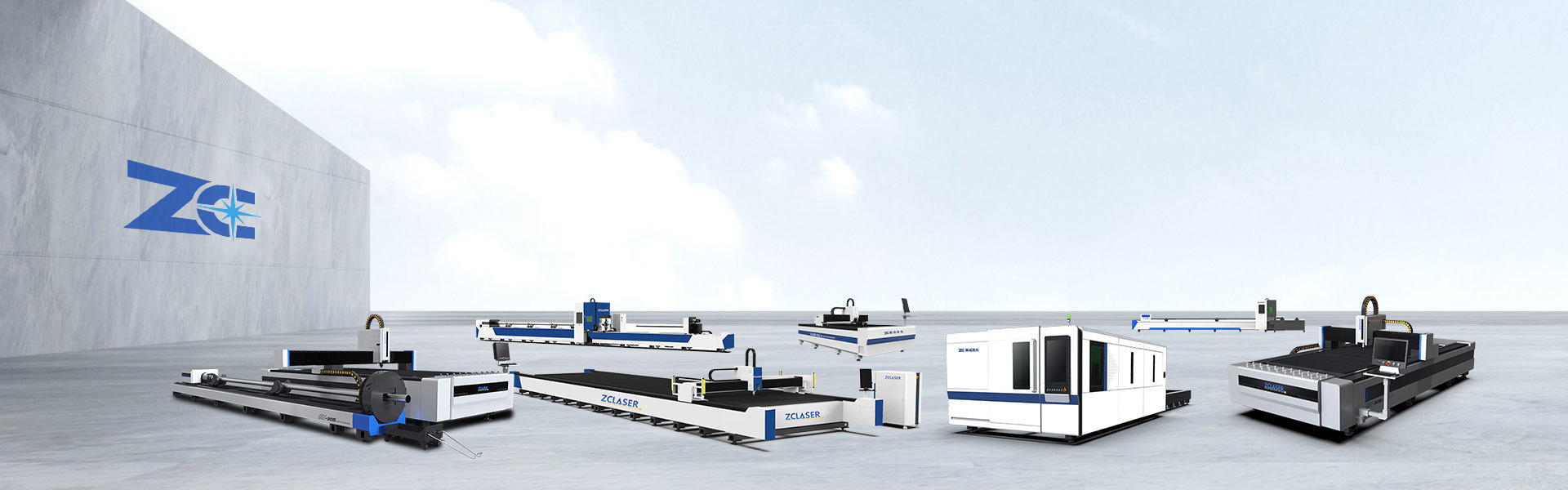

Latest Products

Latest News

Floor 16, Building A, Rongsheng Times International, Licheng District, Jinan City, Shandong Province,China