PRODUCTS

Fiber Laser Cutting Machine

X-Series Open-Frame Single-Platform Laser Cutting Machine

Focusing on the all-water-cooled design of the component, it delivers high power in a compact size—enabling long-lasting cutting without overheating or smoking, while also extending the lifespan of the cutting head.

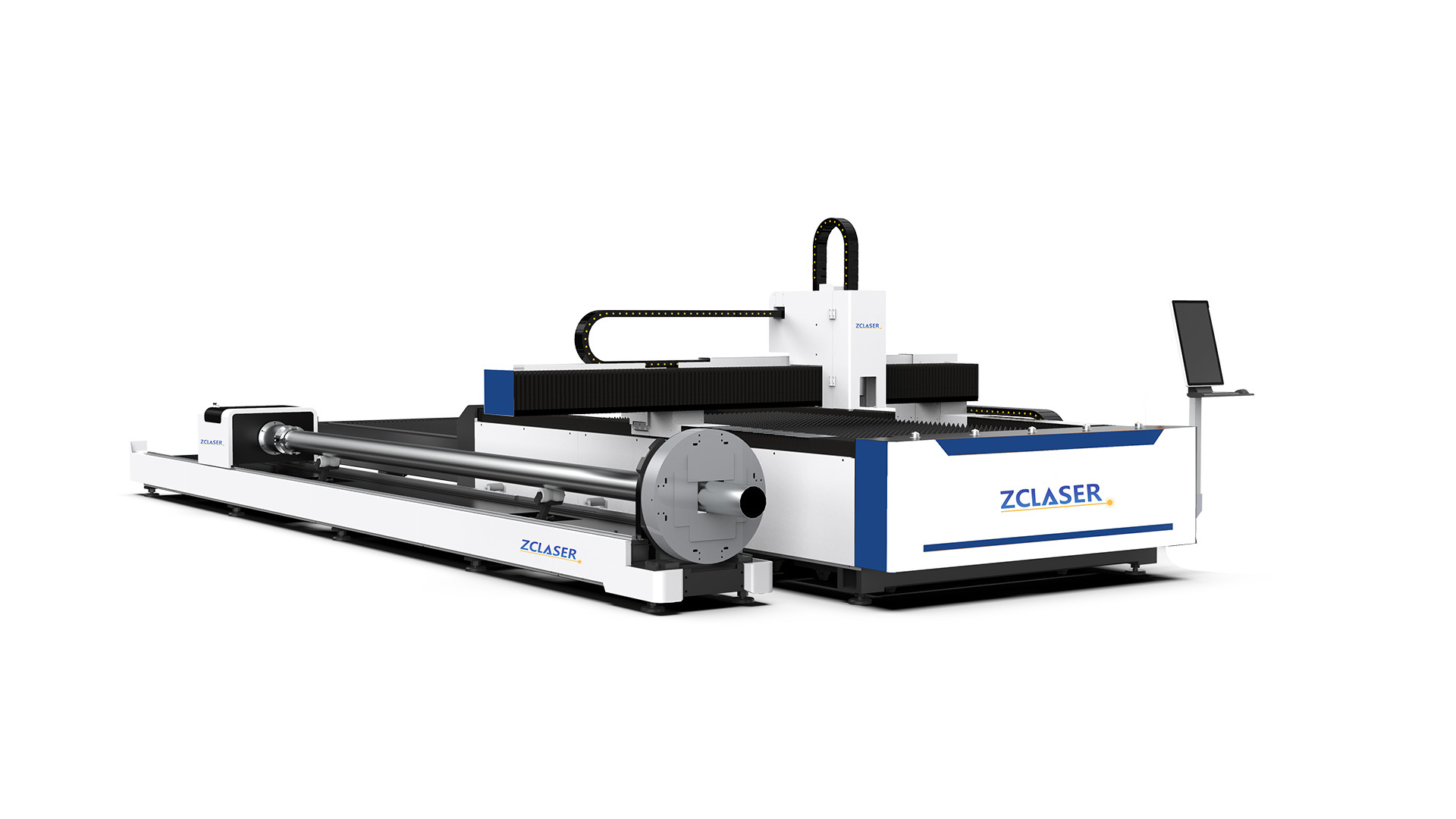

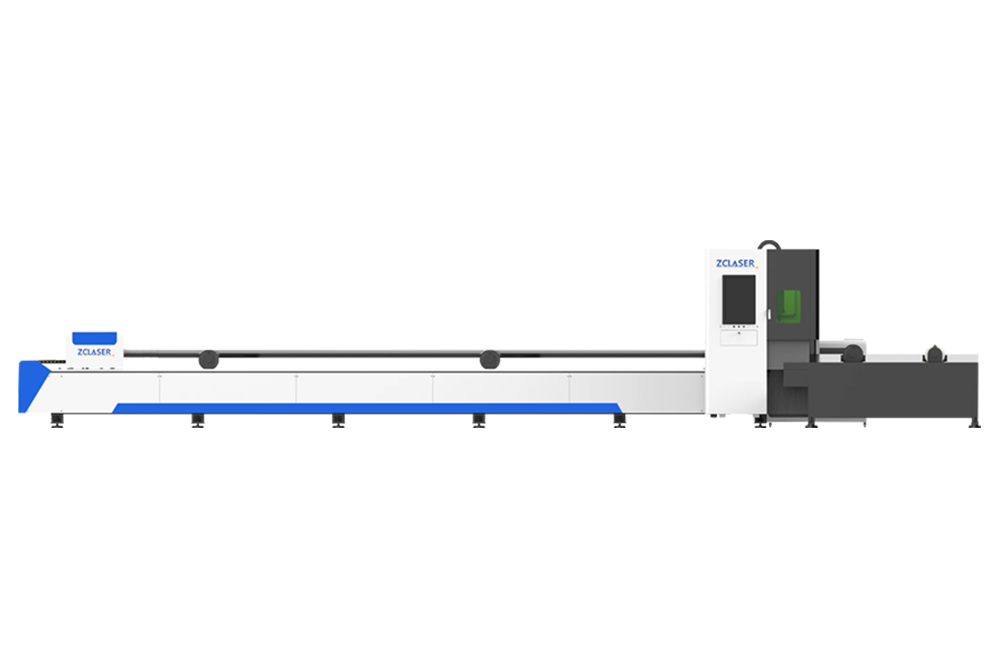

U-Series Single-Plate Tube Fiber Laser Cutting Machine

Integrated plate-and-tube design, offering two functions in one machine, delivering high cost performance while handling a wider range of cutting conditions.

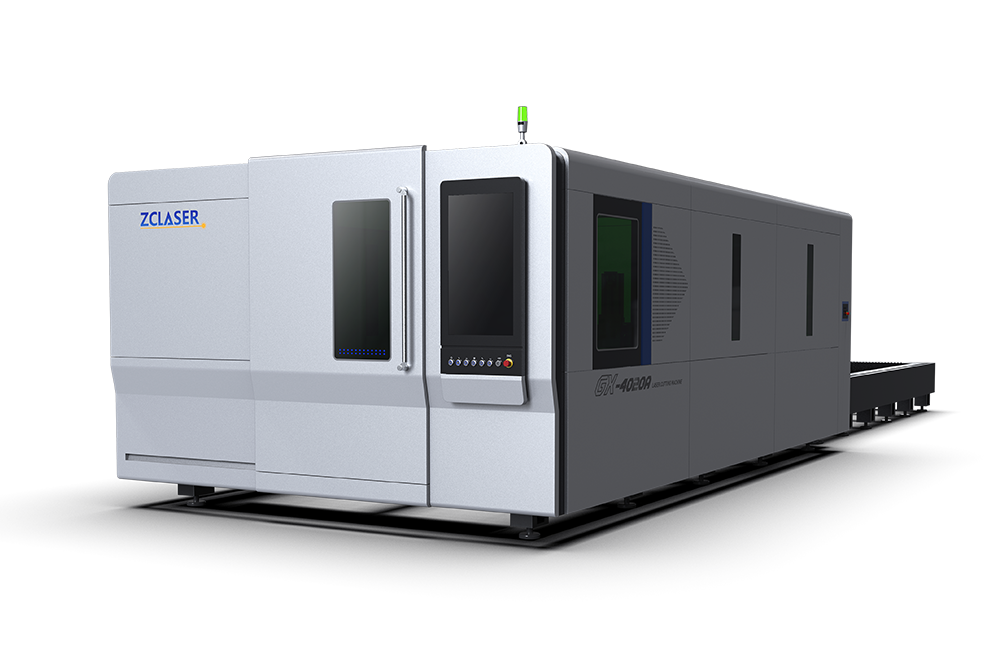

U-Series High-Power Fiber Laser Cutting Machine

Focusing on the all-water-cooled design of the component, it delivers high power in a compact footprint—enabling long-lasting cutting without overheating or smoking, while also extending the lifespan of the cutting head.

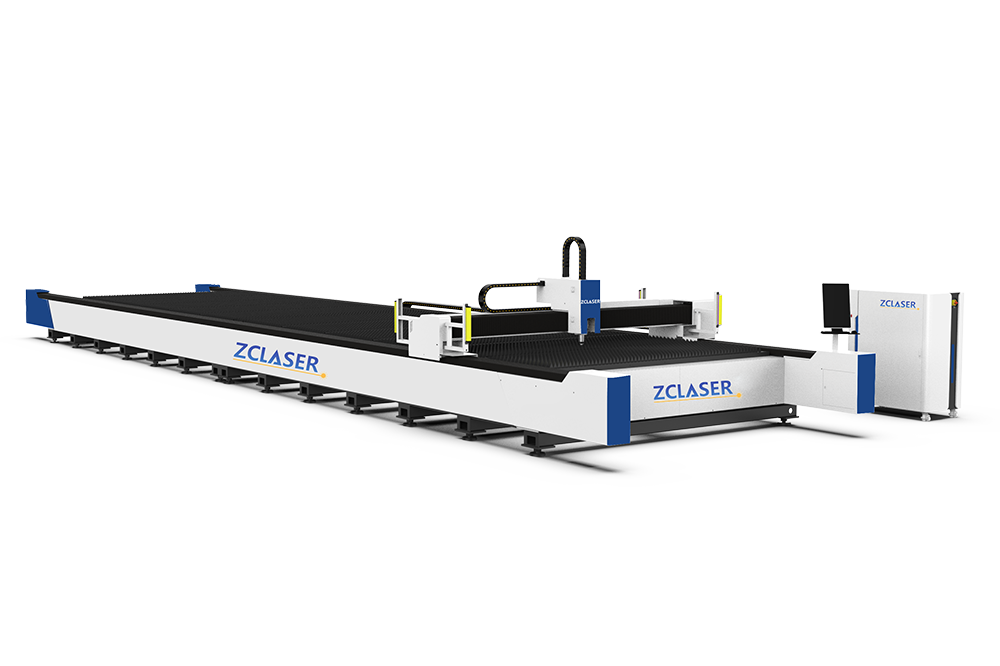

ZC12025W Large-Format Laser Cutting Machine

Available in processing sizes of 16m and 24m, with power output up to 30,000W: It can stably cut medium-to-thick plates (20mm and above) in long batches, and the processing length can be customized according to your needs. The machine is compatible with a wide range of materials.

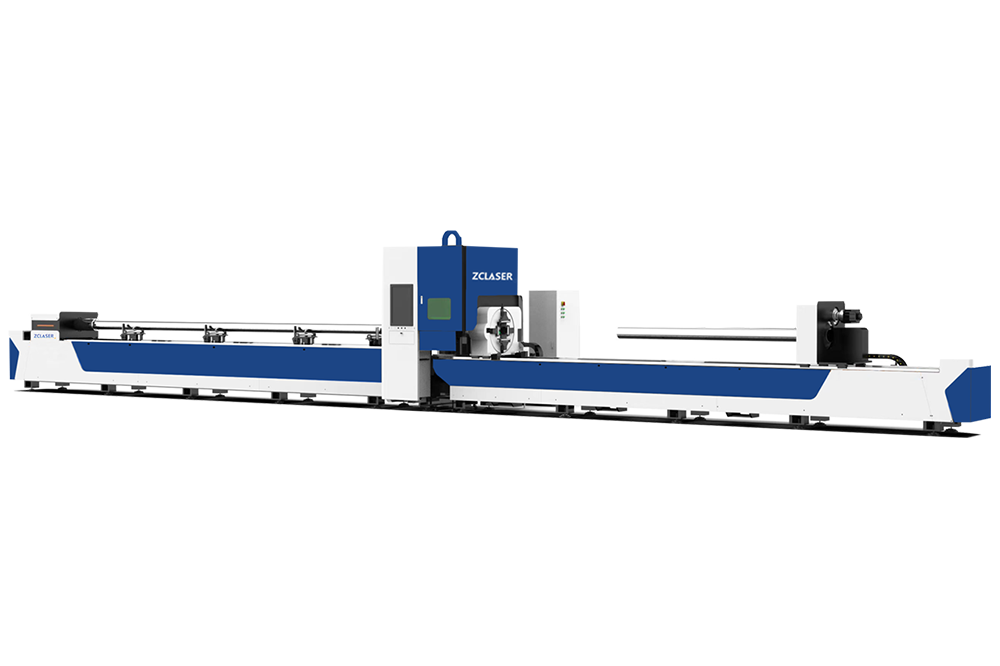

ZC-62TA Tubular Laser Cutting Machine

The front-and-back chuck clamping design is easy to install, effortless to use, and wear-free.

ZC-82TA Professional Fiber Laser Cutting Machine

The front-and-back chuck clamping design is easy to install, effortless to use, and wear-free.

3000W 4000W 6000W 8000W Auto Feeding Tube Metal Laser Cutting Machine for Carbon Steel Tube

Specifically designed for high volume cutting of tubes and pipes provide far greater efficiency than normal laser systems when cutting pipes and tubular metals.Tube and rectangular tube can finish full automatic feeding without human operation. Deformed tubes can achieve artificial semi-automatic feeding. The fast corner response improves cutting efficiency greatly. The workpieces can be unloaded automatically in different areas after cutting.

Iron Steel Fiber Laser Cutting Machine 3KW 6KW CNC Laser Cut Production Line for Coil Metal Sheet

The fully automatic Steel Coils Laser Metal Cutting Machine with Decoiling and Levelling breaks the traditional processing method, and can simultaneously realize the four functions of raw material leveling, feeding, cutting, and unloading.

Portable Gantry Fiber Laser Cutting Machine

The fiber laser cutting machine focuses the laser light emitted from the laser into a high-power density laser beam through the optical path system. The laser beam irradiates the surface of the workpiece to make the workpiece reach the melting point or boiling point, while the high-pressure gas coaxial with the beam blows away the molten or vaporized metal. As the relative position of the beam and the workpiece moves, the material will finally form a slit, so as to achieve the purpose of cutting.

1. Heavy-duty mechanical structure The bed is welded with high-quality carbon steel, which is more stable and durable. The high-strength machine tool is stress-relief annealed at 600℃, with strong structural rigidity, small deformation and vibration, ensuring cutting accuracy. 2. Pneumatic self-centering chuck It has the advantages of high clamping accuracy, fast speed, self-centering gear linkage, and strong pipe bearing capacity. 3. Automatic feeding and automatic loading Fast and high-quality cutting, better quality, trustworthy, higher precision in all aspects, and better after-sales service. 4. Autofocus No human intervention is required, the focusing speed is fast, and the repeatability is about 30 microns.

Fiber laser cutting machine for metal ZC-1390/ZC-1610 is the best cutting tool for thin sheet metal cutting,especially for stainless steel cutting. ZC-1390/ZC-1610 Fiber laser cutting machine has the feature of compact layout, stable optical link, convenient operation and reliable performance.

Ultraviolet Picosecond Precision Laser Glass Cutting Machine

Equipment Advantages 1. The use of ultra-short pulse laser has the advantages of high processing efficiency, small heat-affected zone, and no need for subsequent auxiliary processing, which can achieve "cold" processing. 2.The marble platform X/Y system adopts a linear motor drive system to ensure the accuracy and stability of the platform's high-speed operation; 3. Equipped with high-pixel CCD automatic alignment function to ensure accurateproduct cutting and alignment; 4. Imported high-quality laser generator and optical system, full light path protection, to ensure the long-term stable operationof the machine.

Floor 16, Building A, Rongsheng Times International, Licheng District, Jinan City, Shandong Province,China