ZCLASER Multi-functional Robot Welding Machine

A Laser Welding Machine is an advanced industrial equipment that utilizes a high-energy-density laser beam as a heat source to achieve precise, efficient, and high-quality welding of materials. It is a cornerstone technology in modern manufacturing, offering unparalleled accuracy, minimal heat distortion, and exceptional weld strength for a wide range of metals and alloys, including steel, aluminum, copper, and titanium.

- 产品描述

- parameter

-

- Brand: ZCLASER

- Commodity name: ZCLASER Multi-functional Robot Welding Machine

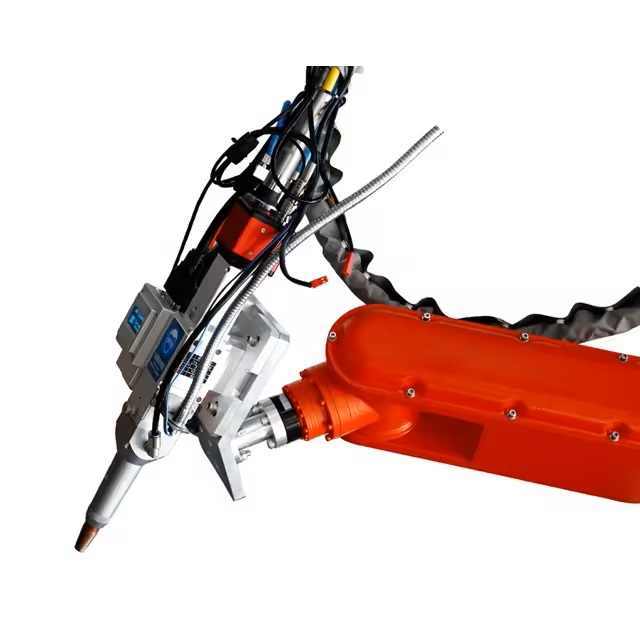

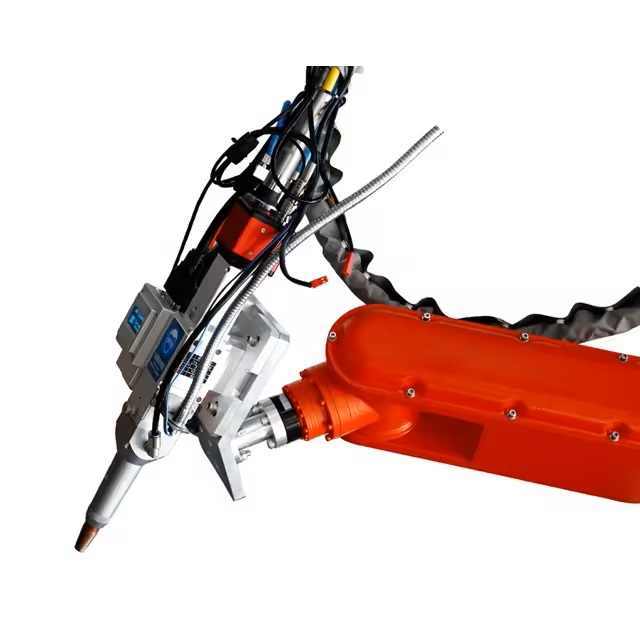

This device combines the flexibility of a robotic arm with the precision of laser welding, making it suitable for a wide range of metal materials. It features multi-axis motion, a dual-mode welding/cutting switch, and intelligent control capabilities. With a power output ranging from 1000 to 3000W (customizable), it is widely used in industries such as automotive and aerospace, ensuring highly efficient and accurate welding.

What is the ZCLASER multi-functional laser welding robot arm?

The ZCLASER multi-functional laser welding robot arm is an advanced industrial device designed to revolutionize metal welding processes. It combines the flexibility of a robotic arm with the precision of laser welding technology, enabling seamless, high-quality welds on a wide range of metal materials.

Here's how it works:

Laser Source: At the heart of the robotic arm is a high-power laser source, specifically designed for welding applications. This laser emits a highly focused beam of light, enabling rapid and precise heating and melting of metal surfaces. The laser’s adjustable power output allows users to tailor the process according to the thickness and type of metal being welded.

Robot arm operation: The integrated robot arm delivers exceptional flexibility and mobility. With its multi-axis motion capability, it can reach intricate angles and tight spaces, ensuring even the most complex welding tasks are completed with ease. The arm’s precise positioning system works in tandem with the laser, maintaining consistent weld quality throughout the process.

Intelligent Control System: The laser welding robot arm is equipped with a state-of-the-art control system that delivers intuitive operation and precise parameter adjustments. Operators can easily set and monitor variables such as welding speed, laser pulse frequency, and focal depth. The system also features real-time monitoring and feedback mechanisms, ensuring optimal performance while minimizing the risk of errors.

Product Details

Machine Features

1. Accuracy: High-precision welding and cutting with minimal deformation.

2. Flexible: Multi-axis robotic arms handle complex tasks.

3. Dual Mode: One-touch switching between welding and cutting, with adjustable parameters.

4. Automation: Enhances productivity, reduces errors, and lowers costs.

5. Versatility: Serving industries such as automotive, aerospace, electronics, and more.

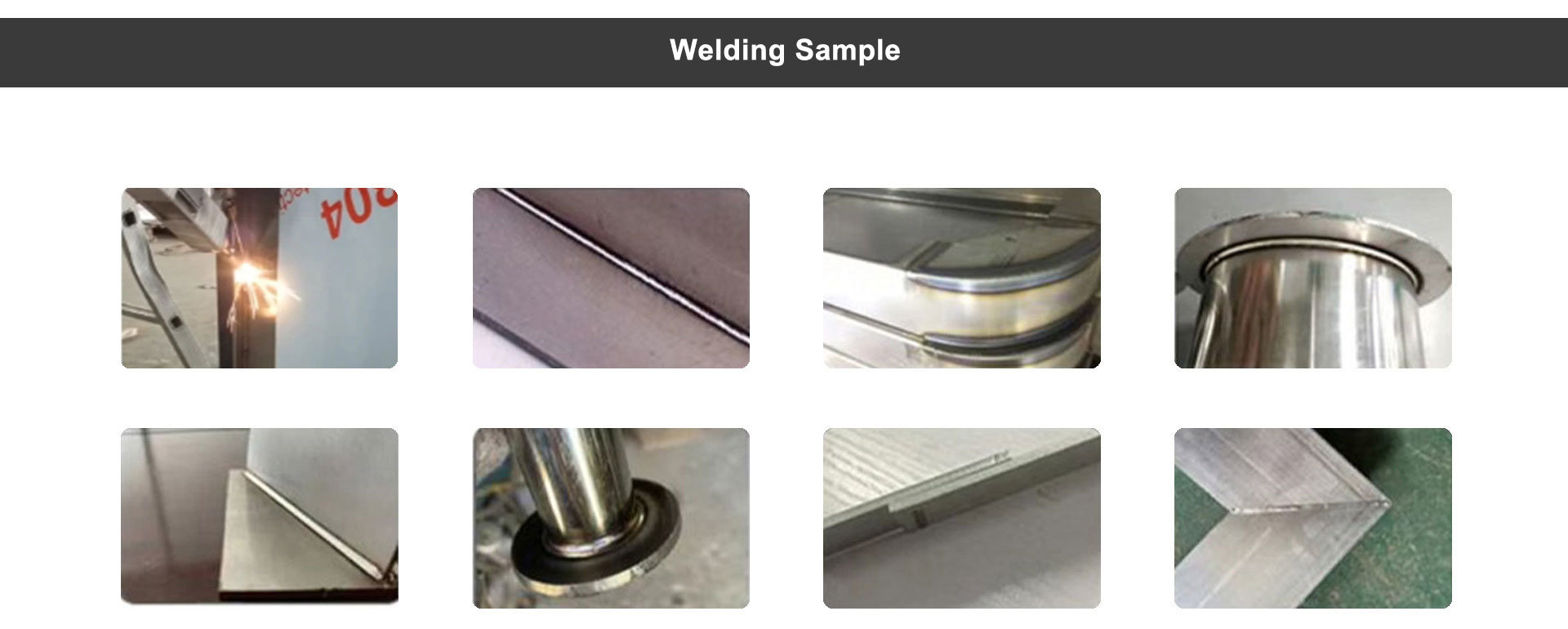

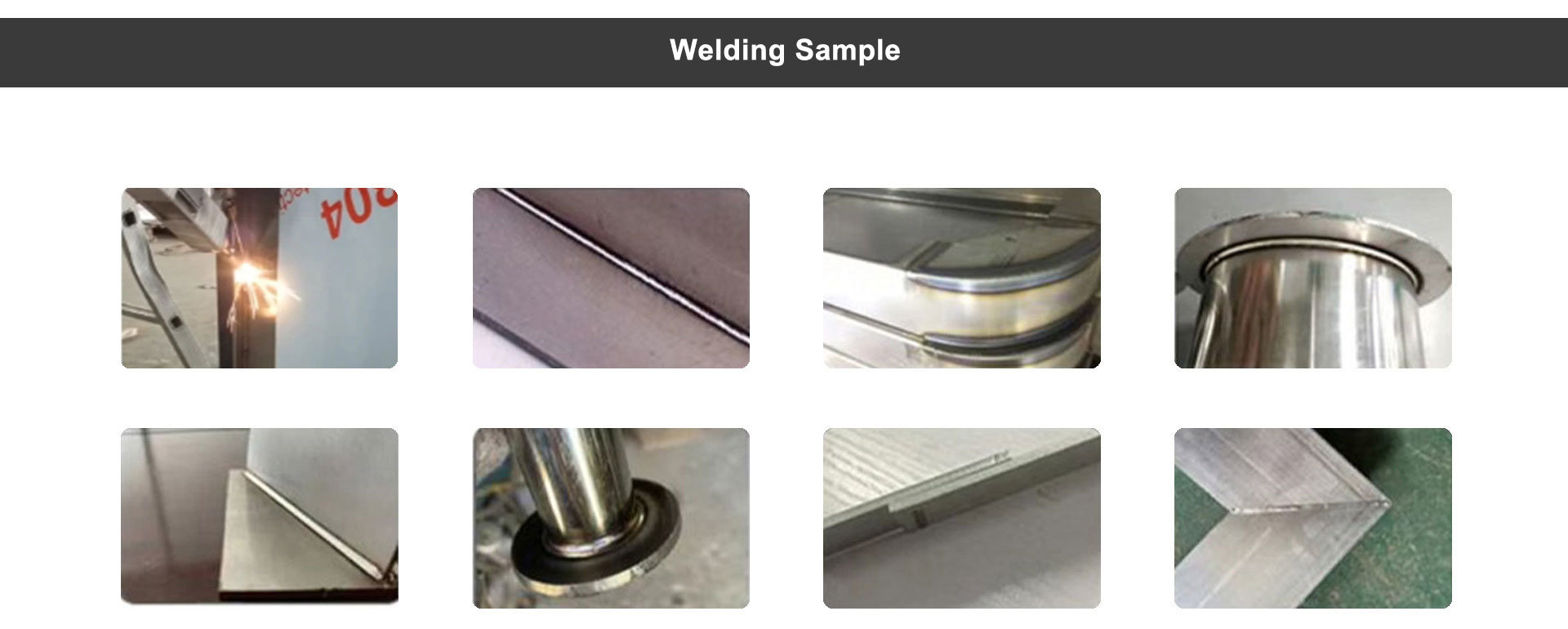

Wide range of applications

It is suitable for hardware processing, automotive components, furniture accessories, heat pipe welding, and embedded parts, among others.

We produce 1000W, 1500W, 2000W, 3000W, and more. We also offer customized machines.

Recommended: 1000–3000 W is ideal for welding a wide range of metal products, including automotive parts, housings for household appliances, and hardware tools. This power range ensures efficient welding speeds suitable for large-scale production, while providing ample energy for optimal melt depth, thereby enhancing weld quality.

High production efficiency

The time it takes for a robotic arm to produce one product is fixed within the same production cycle, and output is also constant—meaning higher product volume leads to greater production efficiency.

Cost savings

It can operate 24 hours a day, effectively reducing labor costs. Additionally, by adopting an industrial robotic operation mode, the automated assembly line saves space, enabling a more compact overall factory layout.

Parameters

Materials

Metal

Laser power

1000W / 1500W / 2000W / 3000W available

Size

1440/1840/2000mm

Welding Power Supply Types

MIG, TIG, STICK

Maximum Coverage Range

1454mm

Weight (kg)

150

Voltage

380V

Repeatability positioning accuracy

±0.08mm

Installation Method

Floor-mounted, ceiling-mounted, wall-mounted

Installation Temperature

0~45℃

Relative humidity

20–80% (no condensation)

IP Rating

Wristband IP67, others IP54

Type

Floor-standing / Bracket-mounted / Inverted

Input/Output Signal

24VDC

Application Scenarios

-

-

参数列表

- Brand: ZCLASER

- Model: Multi-Function Robotic Arm Welding Machine

- Price: $3,300~$3,600

- Delivery period: 30days

- Warranty period: Core components:2 years Other components:1 year

-

Keywords:

welding Robot Arm

new Industrial Robot

Multifunctional Industrial Robot Arm

Welding for Metal

Classification:

Product Description

What is the ZCLASER multi-functional laser welding robot arm?

The ZCLASER multi-functional laser welding robot arm is an advanced industrial device designed to revolutionize metal welding processes. It combines the flexibility of a robotic arm with the precision of laser welding technology, enabling seamless, high-quality welds on a wide range of metal materials.

Here's how it works:

Laser Source: At the heart of the robotic arm is a high-power laser source, specifically designed for welding applications. This laser emits a highly focused beam of light, enabling rapid and precise heating and melting of metal surfaces. The laser’s adjustable power output allows users to tailor the process according to the thickness and type of metal being welded.

Robot arm operation: The integrated robot arm delivers exceptional flexibility and mobility. With its multi-axis motion capability, it can reach intricate angles and tight spaces, ensuring even the most complex welding tasks are completed with ease. The arm’s precise positioning system works in tandem with the laser, maintaining consistent weld quality throughout the process.

Intelligent Control System: The laser welding robot arm is equipped with a state-of-the-art control system that delivers intuitive operation and precise parameter adjustments. Operators can easily set and monitor variables such as welding speed, laser pulse frequency, and focal depth. The system also features real-time monitoring and feedback mechanisms, ensuring optimal performance while minimizing the risk of errors.

Product Details

Machine Features

1. Accuracy: High-precision welding and cutting with minimal deformation.

2. Flexible: Multi-axis robotic arms handle complex tasks.

3. Dual Mode: One-touch switching between welding and cutting, with adjustable parameters.

4. Automation: Enhances productivity, reduces errors, and lowers costs.

5. Versatility: Serving industries such as automotive, aerospace, electronics, and more.

Wide range of applications

It is suitable for hardware processing, automotive components, furniture accessories, heat pipe welding, and embedded parts, among others.

We produce 1000W, 1500W, 2000W, 3000W, and more. We also offer customized machines.

Recommended: 1000–3000 W is ideal for welding a wide range of metal products, including automotive parts, housings for household appliances, and hardware tools. This power range ensures efficient welding speeds suitable for large-scale production, while providing ample energy for optimal melt depth, thereby enhancing weld quality.

High production efficiency

The time it takes for a robotic arm to produce one product is fixed within the same production cycle, and output is also constant—meaning higher product volume leads to greater production efficiency.

Cost savings

It can operate 24 hours a day, effectively reducing labor costs. Additionally, by adopting an industrial robotic operation mode, the automated assembly line saves space, enabling a more compact overall factory layout.

Parameters

| Materials |

Metal |

| Laser power |

1000W / 1500W / 2000W / 3000W available |

| Size |

1440/1840/2000mm |

| Welding Power Supply Types |

MIG, TIG, STICK |

| Maximum Coverage Range |

1454mm |

| Weight (kg) |

150 |

| Voltage |

380V |

| Repeatability positioning accuracy |

±0.08mm |

| Installation Method |

Floor-mounted, ceiling-mounted, wall-mounted |

| Installation Temperature |

0~45℃ |

| Relative humidity |

20–80% (no condensation) |

| IP Rating |

Wristband IP67, others IP54 |

| Type |

Floor-standing / Bracket-mounted / Inverted |

| Input/Output Signal |

24VDC |

Application Scenarios

ZCLASER

Shandong Zhancheng Intelligent Manufacturing Co., Ltd is a professional research, development, production andsales of laser cutting marking equipment company, can be tailored for differententerprises of various non-standard laser equipment. Companies and many large well-known enterprises at home and abroad to establish long- term stability ofhe interactive relations of cooperation, forthe majority of users with the perfect laser processing solutions and thecorresponding supporting facilities, widelyused in auto parts, instrument, measuring tool cutting tool, electronic communications, aerospace, petrochemical, military products, medicine, food,packaging, and various metal and non-metal material marking.and is a leading enterprise in the laser industry.

A Laser Welding Machine is an advanced industrial equipment that utilizes a high-energy-density laser beam as a heat source to achieve precise, efficient, and high-quality welding of materials. It is a cornerstone technology in modern manufacturing, offering unparalleled accuracy, minimal heat distortion, and exceptional weld strength for a wide range of metals and alloys, including steel, aluminum, copper, and titanium.

Qualifications

If you are interested in this product, please complete the following information submitted to us, we will arrange experts to contact you as soon as possible!

Related Products

Related Products

Floor 16, Building A, Rongsheng Times International, Licheng District, Jinan City, Shandong Province,China