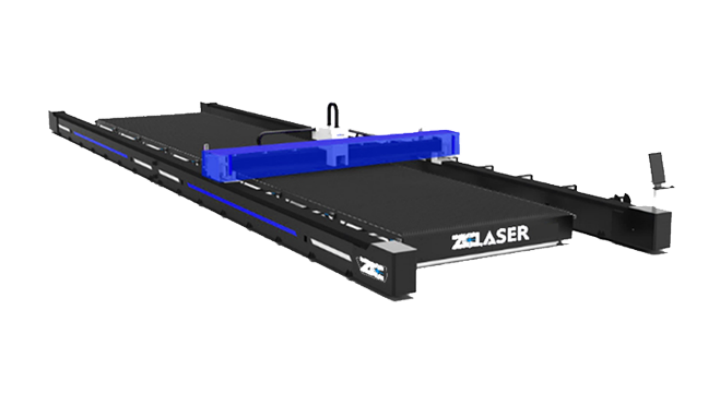

ZC12025W Large-Format Laser Cutting Machine

The metal plate laser cutting machine is an automated metal plate cutting system that utilizes CO₂ or fiber laser beams in conjunction with a CNC controller. It can cut stainless steel plates, chromium steel plates, martensitic steel plates, ferritic steel plates, austenitic steel plates, carbon steel plates, low-carbon steel plates, cold-rolled steel plates, hot-rolled steel plates, galvanized steel plates, pre-galvanized steel plates, aluminum, zinc, copper, brass, as well as titanium, gold, and silver.

This equipment efficiently handles diverse, small-batch, customized, high-quality orders with short lead times. Featuring high precision, speed, and flexibility, it cuts special or complex shapes, progressively replacing traditional sheet metal cutting tools like plasma cutters, flame cutters, waterjet cutters, CNC punches, CNC shears, guillotine shears, and wire cutters.

This equipment offers multiple cutting table sizes (2x3, 2x4, 4x4, 4x8, 5x10, 6x12), laser generator brands (IPG, JPT, Raycus, MAX, RECI), and laser power ranges (180W, 300W, 1500W, 2000W, 3000W, 4000W, 6000W, 8000W, 10000W, 12000W, 15000W, 20000W, 30000W, 40000W, 60000W), all customizable to your sheet metal cutting requirements.

- 产品描述

- parameter

-

- Brand: ZCLASER

- Commodity name: ZC12025W Large-Format Laser Cutting Machine

Available in processing sizes of 16m and 24m, with power output up to 30,000W: It can stably cut medium-to-thick plates (20mm and above) in long batches, and the processing length can be customized according to your needs. The machine is compatible with a wide range of materials.

Features

1. The cutting area is designed with a partitioned dust removal system and a high-volume dust filtration system, delivering powerful suction for thorough cleaning. On both sides of the cutting area, blow-and-suction dust removal devices and smoke purification equipment are installed to effectively eliminate smoke. Additionally, the area features a flame-retardant structure, ensuring safe and secure operations.

2. Non-contact capacitive sensing head that automatically detects edges and adjusts focus for precise positioning, featuring robust protection capabilities, making it ideal for fast cutting of irregularly shaped workpieces.

3. The processing list allows for the simultaneous setup of different板材, specifications, and workpieces, and can even activate an unattended machining mode.

4. Cold-drawn extruded aluminum profiles are lightweight, exhibit excellent rigidity, high precision, superior dynamic performance, and maintain stable structural integrity without easy deformation.

5. The bus control operates quickly, responds swiftly, and offers strong scalability.

6. Zero-clearance ground rail splicing for the machine body ensures consistent side-to-side distances, enabling smooth, vibration-free high-speed operation. The bed frame undergoes secondary annealing to eliminate internal stresses, guaranteeing long-term stability and preventing deformation during extended use.

7. The Longmen beam floating structure features one end of the beam fixed while the other end is free to move, specifically addressing the issue of parallelism between the guide rails on both sides of wide beams and thereby extending the service life of transmission components.Product Details

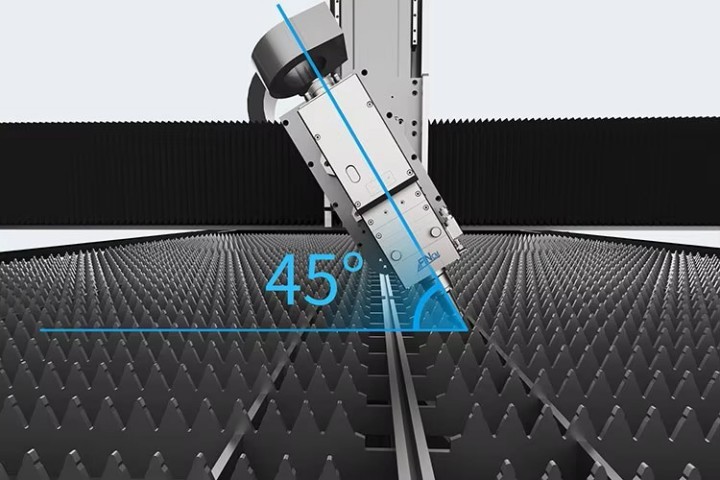

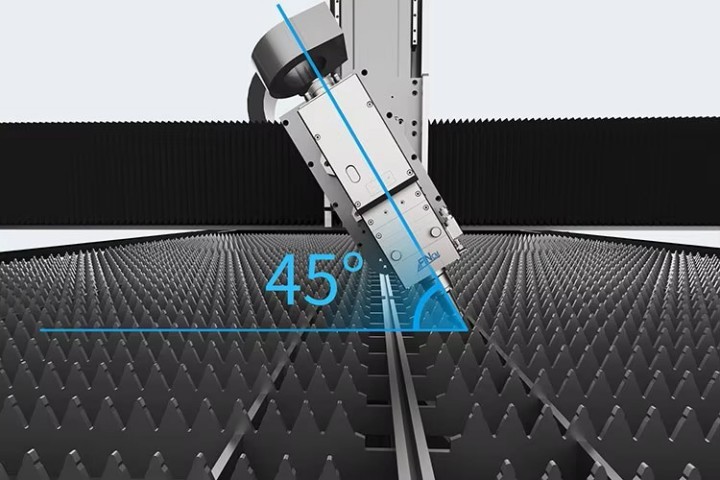

Conical laser cutting system (optional)

This feature employs an AB dual-arm structure, meeting diverse conical cutting needs and enabling 0–45° conical cuts. It effortlessly handles V, X, Y, and other types of conical cuts, satisfying a wide range of machining requirements.

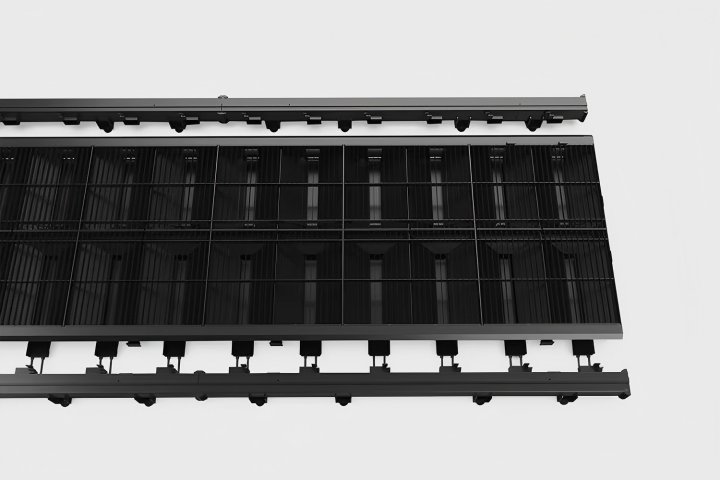

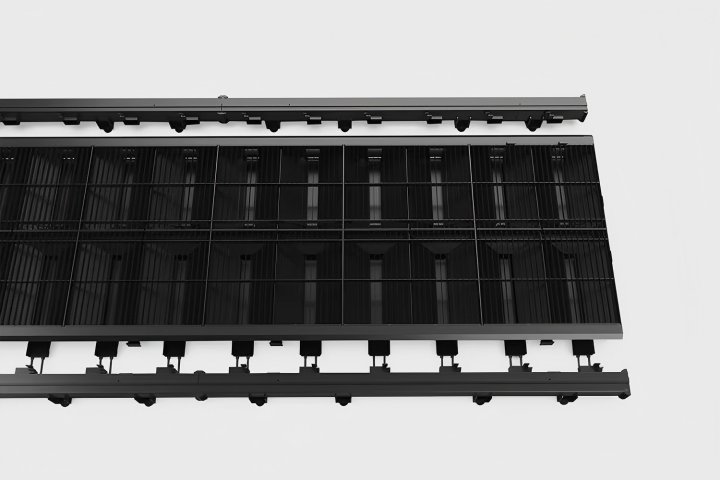

Modular Workbench

1. Enhance cutting accuracy

The segmented bed structure minimizes overall deformation, ensuring stability during operation. Each segment can be adjusted individually to maintain a consistent distance between the cutting head and the material, thereby enhancing cutting accuracy.

2. Enhance Equipment Stability

By distributing weight and pressure across multiple independent support points, the segmented bed minimizes vibrations that could affect the cutting process. This results in improved stability and support, particularly when working with large or heavy materials, ensuring smooth and precise cutting operations.

3. Easier to maintain and replace

The modular design of the segmented bed allows individual sections to be replaced or maintained without disassembling the entire bed. This simplifies maintenance tasks and reduces both costs and downtime.

4. Enhance Thermal Stability

During the laser cutting process, the machine bed is exposed to high temperatures. The segmented bed design effectively dissipates heat, minimizing deformation caused by thermal expansion. Additionally, the gaps between the individual segments further enhance heat dissipation, helping to maintain the overall stability of the bed.

5. Enhance Production Efficiency

Segmented bed installations and adjustments are faster, and their resistance to significant deformation during operation reduces downtime. This, in turn, leads to higher production efficiency.

6. Adapting to materials of different sizes and shapes

The segmented bed can be adjusted to accommodate materials of various sizes and shapes.

Whether handling large panels or workpieces with complex shapes, the segmented bed provides flexible support.

Customizable extra-large specifications

1. High-strength plate-welded bed frame, featuring a split design between the bed frame and the worktable for greater machining versatility and extended service life.

Lightning punching/conical cutting—efficient and time-saving

1. Equipped with an auto-focusing laser head, it delivers high-speed jet perforation, making it ideal for high-speed cutting of medium-to-thick板材. The small-aperture cutting ensures precise, slag-free results, while the thick-plate corners remain smooth and burr-free.

And thick plates. Fine cutting with small apertures produces zero slag, and the corners of thick plates are smooth and free of burrs.

2. Optional conical cutting function breaks through the limitations of straight cross-sections. It supports various conical cuts, including V, Y, X, and K types. The resulting cross-section is smooth after forming.

Smart cutting system boosts quality and reduces costs.

1. Develop unique cutting processes tailored for specialized materials such as high-strength steel and wear-resistant steel, designed specifically for customers in the steel structure industry.

2. The professional layout and nesting software is highly integrated with the intelligent laser cutting system, featuring advanced processes such as smart layout, automatic edge detection, and sharp-angle smoothing—enabling effortless improvements in quality while reducing costs.

Processing specifications are customizable.

Processing specifications available in 16m and 24m, with power up to 30,000W:

Capable of long-term, stable batch cutting of medium-to-thick plates exceeding 20mm; processing lengths can be customized according to requirements, and a wide variety of materials can be processed.

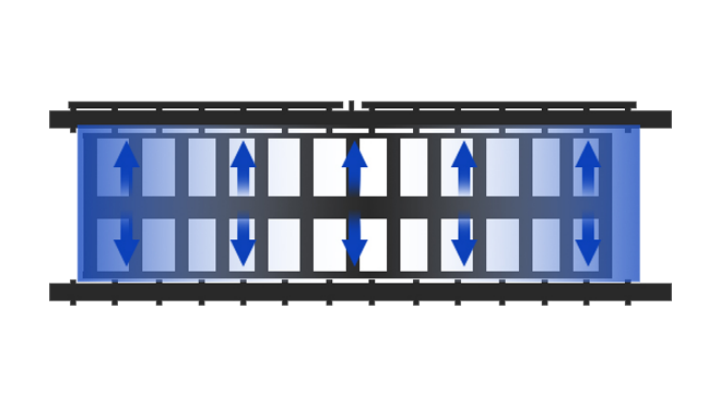

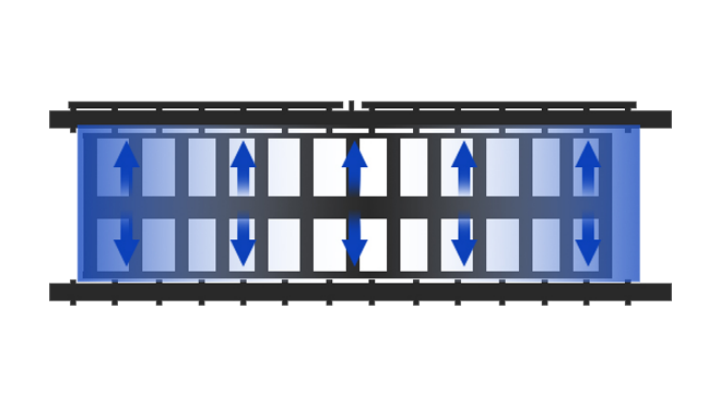

Zonal ventilation

The bed frame features zoned ventilation on both the left and right sides, with butterfly valves controlling the overall suction power—resulting in stronger suction and smoother smoke exhaust.

Aerospace aluminum beam

It boasts excellent dynamic performance, strong resistance to deformation, lightweight design, high strength, and superior durability. Additionally, it enables more accurate measurement for enhanced dynamic response, ultimately boosting machining efficiency.

Beam Safety Light Curtain

The measurement section is equipped with safety light curtains that can effectively detect any opaque objects entering the light curtain area beyond the detection accuracy, ensuring production safety.

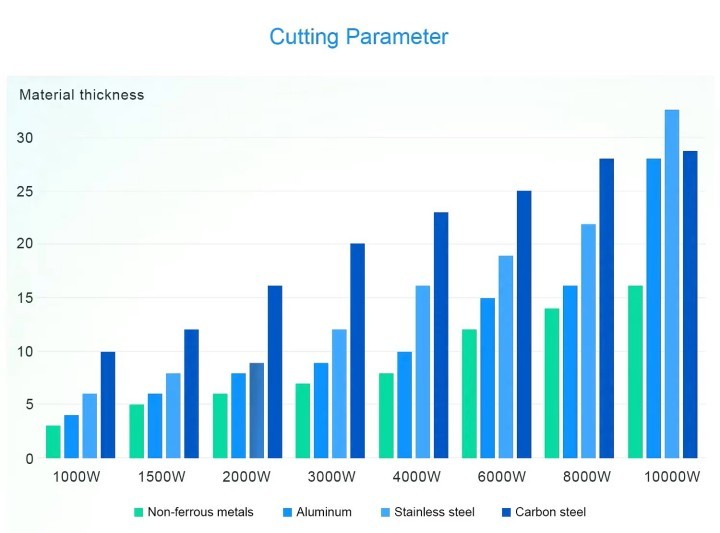

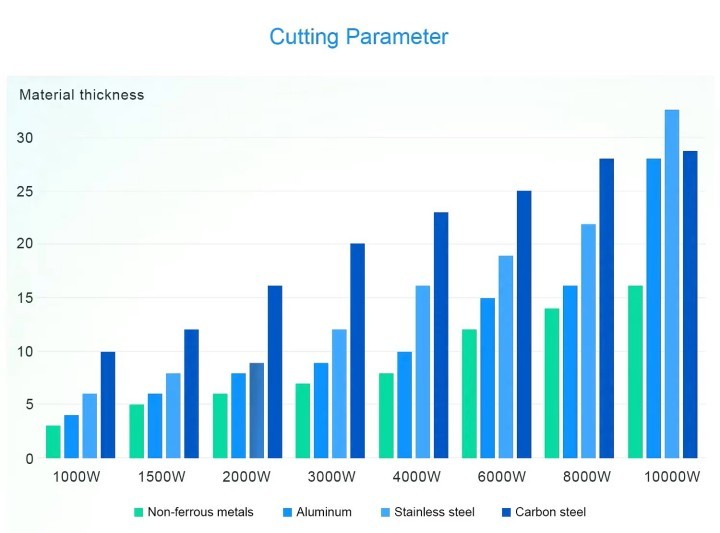

Cutting parameters

Product Specifications

Laser power

12000W-30000W

Laser Type

Fiber Laser

Applicable Materials

Metal

Cutting thickness

1–50 mm, customizable

Cooling Method

Water-Cooled

Is it CNC?

Is

Supported Graphics Formats

AI, PLT, DXF, BMP, Dst, Dwg, LAS, DXP

Control software

FSCUT

Operation Mode

Continuous wave

Weight (kg)

8000

Cutting area

3250 × 24,000 mm

Cutting speed

100

Working Humidity

0–40°C

Laser cutting head

Raytools Fiber Laser Cutting Head

Servo Motor Brands

Inovance

Applicable Industries

Metal Cutting Industry

Application Scenarios

-

-

参数列表

- Brand: ZCLASER

- Model: ZC12025W

- Price: $53,300~$54,700

- Delivery period: 30days

- Warranty period: Core components:2 years Other components:1 year

-

Keywords:

Laser Cutting Machine

bmp Supported Laser Cutting Machines

high-performance 20000w Metal Plate Cnc Fiber Laser Cutter Machin

Classification:

Product Description

Features

1. The cutting area is designed with a partitioned dust removal system and a high-volume dust filtration system, delivering powerful suction for thorough cleaning. On both sides of the cutting area, blow-and-suction dust removal devices and smoke purification equipment are installed to effectively eliminate smoke. Additionally, the area features a flame-retardant structure, ensuring safe and secure operations.

2. Non-contact capacitive sensing head that automatically detects edges and adjusts focus for precise positioning, featuring robust protection capabilities, making it ideal for fast cutting of irregularly shaped workpieces.

3. The processing list allows for the simultaneous setup of different板材, specifications, and workpieces, and can even activate an unattended machining mode.

4. Cold-drawn extruded aluminum profiles are lightweight, exhibit excellent rigidity, high precision, superior dynamic performance, and maintain stable structural integrity without easy deformation.

5. The bus control operates quickly, responds swiftly, and offers strong scalability.

6. Zero-clearance ground rail splicing for the machine body ensures consistent side-to-side distances, enabling smooth, vibration-free high-speed operation. The bed frame undergoes secondary annealing to eliminate internal stresses, guaranteeing long-term stability and preventing deformation during extended use.

7. The Longmen beam floating structure features one end of the beam fixed while the other end is free to move, specifically addressing the issue of parallelism between the guide rails on both sides of wide beams and thereby extending the service life of transmission components.

Product Details

Conical laser cutting system (optional)

This feature employs an AB dual-arm structure, meeting diverse conical cutting needs and enabling 0–45° conical cuts. It effortlessly handles V, X, Y, and other types of conical cuts, satisfying a wide range of machining requirements.

Modular Workbench

1. Enhance cutting accuracy

The segmented bed structure minimizes overall deformation, ensuring stability during operation. Each segment can be adjusted individually to maintain a consistent distance between the cutting head and the material, thereby enhancing cutting accuracy.

2. Enhance Equipment Stability

By distributing weight and pressure across multiple independent support points, the segmented bed minimizes vibrations that could affect the cutting process. This results in improved stability and support, particularly when working with large or heavy materials, ensuring smooth and precise cutting operations.

3. Easier to maintain and replace

The modular design of the segmented bed allows individual sections to be replaced or maintained without disassembling the entire bed. This simplifies maintenance tasks and reduces both costs and downtime.

4. Enhance Thermal Stability

During the laser cutting process, the machine bed is exposed to high temperatures. The segmented bed design effectively dissipates heat, minimizing deformation caused by thermal expansion. Additionally, the gaps between the individual segments further enhance heat dissipation, helping to maintain the overall stability of the bed.

5. Enhance Production Efficiency

Segmented bed installations and adjustments are faster, and their resistance to significant deformation during operation reduces downtime. This, in turn, leads to higher production efficiency.

6. Adapting to materials of different sizes and shapes

The segmented bed can be adjusted to accommodate materials of various sizes and shapes.

Whether handling large panels or workpieces with complex shapes, the segmented bed provides flexible support.

Customizable extra-large specifications

1. High-strength plate-welded bed frame, featuring a split design between the bed frame and the worktable for greater machining versatility and extended service life.

Lightning punching/conical cutting—efficient and time-saving

1. Equipped with an auto-focusing laser head, it delivers high-speed jet perforation, making it ideal for high-speed cutting of medium-to-thick板材. The small-aperture cutting ensures precise, slag-free results, while the thick-plate corners remain smooth and burr-free.

And thick plates. Fine cutting with small apertures produces zero slag, and the corners of thick plates are smooth and free of burrs.

2. Optional conical cutting function breaks through the limitations of straight cross-sections. It supports various conical cuts, including V, Y, X, and K types. The resulting cross-section is smooth after forming.

Smart cutting system boosts quality and reduces costs.

1. Develop unique cutting processes tailored for specialized materials such as high-strength steel and wear-resistant steel, designed specifically for customers in the steel structure industry.

2. The professional layout and nesting software is highly integrated with the intelligent laser cutting system, featuring advanced processes such as smart layout, automatic edge detection, and sharp-angle smoothing—enabling effortless improvements in quality while reducing costs.

Processing specifications are customizable.

Processing specifications available in 16m and 24m, with power up to 30,000W:

Capable of long-term, stable batch cutting of medium-to-thick plates exceeding 20mm; processing lengths can be customized according to requirements, and a wide variety of materials can be processed.

Zonal ventilation

The bed frame features zoned ventilation on both the left and right sides, with butterfly valves controlling the overall suction power—resulting in stronger suction and smoother smoke exhaust.

Aerospace aluminum beam

It boasts excellent dynamic performance, strong resistance to deformation, lightweight design, high strength, and superior durability. Additionally, it enables more accurate measurement for enhanced dynamic response, ultimately boosting machining efficiency.

Beam Safety Light Curtain

The measurement section is equipped with safety light curtains that can effectively detect any opaque objects entering the light curtain area beyond the detection accuracy, ensuring production safety.

Cutting parameters

Product Specifications

Laser power |

12000W-30000W |

Laser Type |

Fiber Laser |

Applicable Materials |

Metal |

Cutting thickness |

1–50 mm, customizable |

Cooling Method |

Water-Cooled |

Is it CNC? |

Is |

Supported Graphics Formats |

AI, PLT, DXF, BMP, Dst, Dwg, LAS, DXP |

Control software |

FSCUT |

Operation Mode |

Continuous wave |

Weight (kg) |

8000 |

Cutting area |

3250 × 24,000 mm |

Cutting speed |

100 |

Working Humidity |

0–40°C |

Laser cutting head |

Raytools Fiber Laser Cutting Head |

Servo Motor Brands |

Inovance |

Applicable Industries |

Metal Cutting Industry |

Application Scenarios

ZCLASER

Shandong Zhancheng Intelligent Manufacturing Co., Ltd is a professional research, development, production andsales of laser cutting marking equipment company, can be tailored for differententerprises of various non-standard laser equipment. Companies and many large well-known enterprises at home and abroad to establish long- term stability ofhe interactive relations of cooperation, forthe majority of users with the perfect laser processing solutions and thecorresponding supporting facilities, widelyused in auto parts, instrument, measuring tool cutting tool, electronic communications, aerospace, petrochemical, military products, medicine, food,packaging, and various metal and non-metal material marking.and is a leading enterprise in the laser industry.

The metal plate laser cutting machine is an automated metal plate cutting system that utilizes CO₂ or fiber laser beams in conjunction with a CNC controller. It can cut stainless steel plates, chromium steel plates, martensitic steel plates, ferritic steel plates, austenitic steel plates, carbon steel plates, low-carbon steel plates, cold-rolled steel plates, hot-rolled steel plates, galvanized steel plates, pre-galvanized steel plates, aluminum, zinc, copper, brass, as well as titanium, gold, and silver.

This equipment efficiently handles diverse, small-batch, customized, high-quality orders with short lead times. Featuring high precision, speed, and flexibility, it cuts special or complex shapes, progressively replacing traditional sheet metal cutting tools like plasma cutters, flame cutters, waterjet cutters, CNC punches, CNC shears, guillotine shears, and wire cutters.

This equipment offers multiple cutting table sizes (2x3, 2x4, 4x4, 4x8, 5x10, 6x12), laser generator brands (IPG, JPT, Raycus, MAX, RECI), and laser power ranges (180W, 300W, 1500W, 2000W, 3000W, 4000W, 6000W, 8000W, 10000W, 12000W, 15000W, 20000W, 30000W, 40000W, 60000W), all customizable to your sheet metal cutting requirements.

Qualifications

If you are interested in this product, please complete the following information submitted to us, we will arrange experts to contact you as soon as possible!

Related Products

Related Products

Floor 16, Building A, Rongsheng Times International, Licheng District, Jinan City, Shandong Province,China