E-Series Switchboard Tube Fiber Laser Cutting Machine

- 产品描述

- parameter

-

- Brand: ZCLASER

- Commodity name: E-Series Switchboard Tube Fiber Laser Cutting Machine

Ruixu Laser Device

1. Dual-purpose device

Dual-purpose functionality saves both cost and space. It can process not only metal sheets but also a variety of metal tubes, significantly boosting productivity.

2. Integrated high-capacity dust removal system.

3. The 10-second exchange platform makes loading and unloading faster and more convenient.

4. A robust steel bed frame ensures the machine remains intact and functional for 20 years without deformation.

5. Aviation-grade aluminum beams enable the machine to achieve higher operating speeds.Product Details

Aluminum column beams

This beam features a lightweight cast structure, which undergoes rough machining after annealing to relieve internal stresses. It is then refined through a secondary vibration aging process, effectively addressing the stresses introduced during both casting and machining—and ultimately enhancing the beam's overall stability.

Water-cooling system

B Brand: S&A or HANLI Chiller

Details: Dual cooling function—hot water for the laser head and chilled water for the laser unit—keeps both components at a stable temperature, ensuring optimal performance.

Ruixu Laser器

Ruixu Laser is China's largest laser manufacturer, capable of cutting materials such as carbon steel, stainless steel, and aluminum. Known for their exceptional quality and long service life, these lasers are perfectly suited for 24-hour continuous operation. Additionally, we offer a range of other laser brands for your selection, including MAX, RECI, BWT, IPG, JPT, and more.

Platform automatic exchange

By implementing a dual-platform automatic exchange system, the platform switching time is reduced to 20–25 seconds, significantly boosting operational efficiency.

Thick-walled carbon steel plate welding bed.Featuring a high-quality carbon steel welded bed for enhanced stability and durability. The high-strength machine tool undergoes 600°C stress-relief annealing, ensuring robust structural rigidity, minimal deformation, and low vibration—guaranteeing precise cutting accuracy.

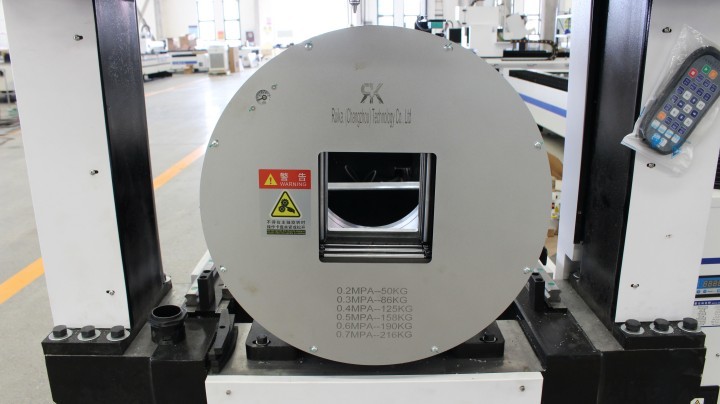

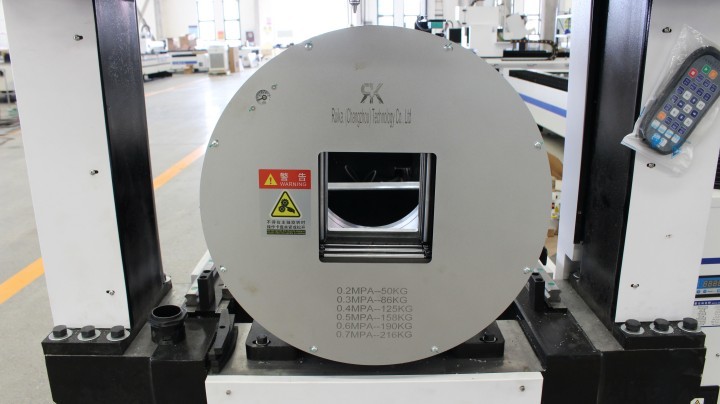

Pneumatic Chuck

Fully automatic pneumatic chucks accommodate round tubes with diameters ranging from 20 to 240 mm, as well as square tubes from 20 to 240 mm. Equipped with a gear-driven system for extended durability—without damaging the raw material tubing.

Laser cutting head

3 protective lenses for effective safeguarding of the collimating and focusing lens. Dual-direction optical water cooling system to significantly extend continuous operation time. Automatic focus adjustment saves operator time and makes the system easy to learn.

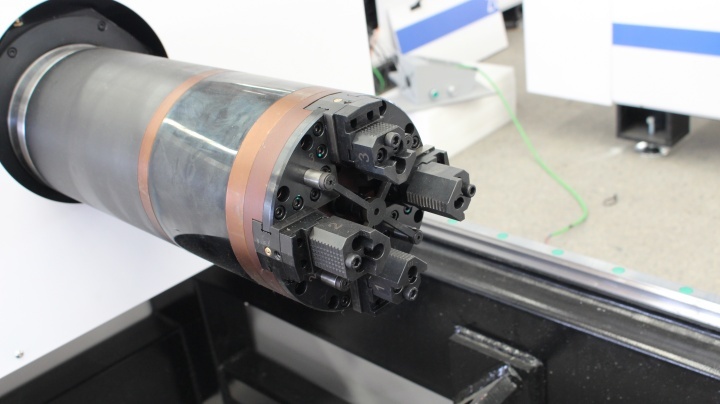

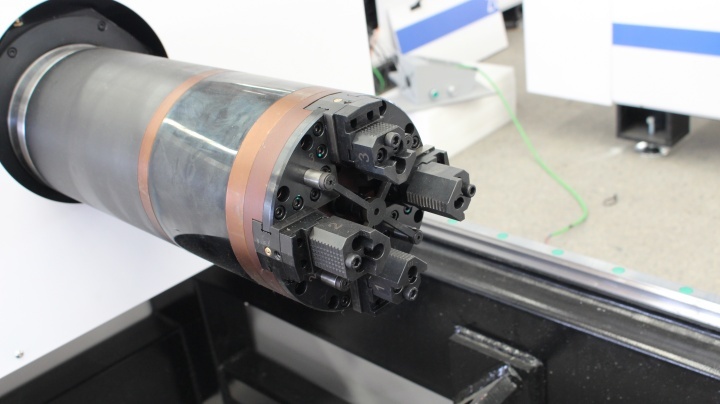

Fully Automatic Dual Pneumatic Chuck

1) One-click chuck opening and automatic centering will reduce loading and unloading wait times.

2) Pneumatically operated clamps: Feature large, consistent clamping force to prevent heavy tubes from loosening or slipping, ensuring cutting accuracy.

3) The special support frame prevents bending and deformation of the pipe, enhances cutting accuracy, and extends the service life of the chuck.Product Specifications

Model

ES-3015

ES-4020

ES-6025

Plane Cutting Parameters

Pipe Cutting Parameters

Plane Cutting Parameters

Pipe Cutting Parameters

Plane Cutting Parameters

Pipe Cutting Parameters

Processing Area

3050mm x 1530mm

Round tubes: ø20mm–ø350mm × 6100mm Square tubes: □20mm–□250mm × 6100mm

4000mm x 2000mm

Round tubes: ø20mm–ø350mm × 6100mm Square tubes: □20mm–□250mm × 6100mm

6000mm x 2500mm

Round tubes: ø20mm–ø350mm × 6100mm Square tubes: □20mm–□250mm × 6100mm

Laser power

1.5 kW - 6 kW (optional)

1.5 kW – 12 kW (optional)

1.5 kW – 12 kW (optional)

X-axis travel

1500mm

350mm

2000mm

350mm

2500mm

350mm

Y-axis travel

3000mm

6100mm

4000mm

6100mm

6000mm

6100mm

Maximum positioning speed on the X/Y axes

X: 88 m/min

Y: 74 m/min

50 m/min

X: 88 m/min

Y: 74 m/min

50 m/min

X: 88 m/min

Y: 74 m/min

50 m/min

X/Y-axis positioning accuracy

±0.05 mm/m

/

±0.05 mm/m

/

±0.05 mm/m

/

X/Y-axis positioning repeatability

±0.05 mm/m

/

±0.05 mm/m

/

±0.05 mm/m

/

Maximum acceleration

0.5G

Application scenarios

Fiber laser cutting equipment is suitable for cutting metals, including stainless steel, low-carbon steel plates (tubes), carbon steel, alloy steel plates, spring steel, iron sheets, galvanized iron, galvanized steel sheets, aluminum plates, copper plates, brass plates, bronze plates, gold plates, silver plates, titanium plates, and various metal sheets, as well as tubes and pipes. The achievable cutting thickness varies depending on the specific laser power settings chosen for the sheet metal laser cutting machine.

-

-

参数列表

- Brand: ZCLASER

- Model: E-Series

- Price: $20,799 ~ $24,799

- Delivery period: 1 unit/25 days

- Warranty period: 2 years warranty for core components, 3 years warranty for the whole machine

-

Keywords:

laser cutting machine

Tube Pipe Fiber Laser Cutting Machine

Cnc Plate and Tube Integrated Fiber Laser Cutting Machine

1500W/2000W/3000W Tube Laser Cutting Machine

Classification:

Product Description

Ruixu Laser Device

1. Dual-purpose device

Dual-purpose functionality saves both cost and space. It can process not only metal sheets but also a variety of metal tubes, significantly boosting productivity.

2. Integrated high-capacity dust removal system.

3. The 10-second exchange platform makes loading and unloading faster and more convenient.

4. A robust steel bed frame ensures the machine remains intact and functional for 20 years without deformation.

5. Aviation-grade aluminum beams enable the machine to achieve higher operating speeds.

Product Details

Aluminum column beams

This beam features a lightweight cast structure, which undergoes rough machining after annealing to relieve internal stresses. It is then refined through a secondary vibration aging process, effectively addressing the stresses introduced during both casting and machining—and ultimately enhancing the beam's overall stability.

Water-cooling system

B Brand: S&A or HANLI Chiller

Details: Dual cooling function—hot water for the laser head and chilled water for the laser unit—keeps both components at a stable temperature, ensuring optimal performance.

Ruixu Laser器

Ruixu Laser is China's largest laser manufacturer, capable of cutting materials such as carbon steel, stainless steel, and aluminum. Known for their exceptional quality and long service life, these lasers are perfectly suited for 24-hour continuous operation. Additionally, we offer a range of other laser brands for your selection, including MAX, RECI, BWT, IPG, JPT, and more.

Platform automatic exchange

By implementing a dual-platform automatic exchange system, the platform switching time is reduced to 20–25 seconds, significantly boosting operational efficiency.

Thick-walled carbon steel plate welding bed.

Featuring a high-quality carbon steel welded bed for enhanced stability and durability. The high-strength machine tool undergoes 600°C stress-relief annealing, ensuring robust structural rigidity, minimal deformation, and low vibration—guaranteeing precise cutting accuracy.

Pneumatic Chuck

Fully automatic pneumatic chucks accommodate round tubes with diameters ranging from 20 to 240 mm, as well as square tubes from 20 to 240 mm. Equipped with a gear-driven system for extended durability—without damaging the raw material tubing.

Laser cutting head

3 protective lenses for effective safeguarding of the collimating and focusing lens. Dual-direction optical water cooling system to significantly extend continuous operation time. Automatic focus adjustment saves operator time and makes the system easy to learn.

Fully Automatic Dual Pneumatic Chuck

1) One-click chuck opening and automatic centering will reduce loading and unloading wait times.

2) Pneumatically operated clamps: Feature large, consistent clamping force to prevent heavy tubes from loosening or slipping, ensuring cutting accuracy.

3) The special support frame prevents bending and deformation of the pipe, enhances cutting accuracy, and extends the service life of the chuck.

Product Specifications

Model |

ES-3015 |

ES-4020 |

ES-6025 |

|||

|

Plane Cutting Parameters |

Pipe Cutting Parameters |

Plane Cutting Parameters |

Pipe Cutting Parameters |

Plane Cutting Parameters |

Pipe Cutting Parameters |

Processing Area |

3050mm x 1530mm |

Round tubes: ø20mm–ø350mm × 6100mm

Square tubes: □20mm–□250mm × 6100mm |

4000mm x 2000mm |

Round tubes: ø20mm–ø350mm × 6100mm

Square tubes: □20mm–□250mm × 6100mm |

6000mm x 2500mm |

Round tubes: ø20mm–ø350mm × 6100mm

Square tubes: □20mm–□250mm × 6100mm |

Laser power |

1.5 kW - 6 kW (optional) |

1.5 kW – 12 kW (optional) |

1.5 kW – 12 kW (optional) |

|||

X-axis travel |

1500mm |

350mm |

2000mm |

350mm |

2500mm |

350mm |

Y-axis travel |

3000mm |

6100mm |

4000mm |

6100mm |

6000mm |

6100mm |

Maximum positioning speed on the X/Y axes |

X: 88 m/min Y: 74 m/min |

50 m/min |

X: 88 m/min Y: 74 m/min |

50 m/min |

X: 88 m/min Y: 74 m/min |

50 m/min |

X/Y-axis positioning accuracy |

±0.05 mm/m |

/

|

±0.05 mm/m |

/

|

±0.05 mm/m |

/

|

X/Y-axis positioning repeatability |

±0.05 mm/m |

/

|

±0.05 mm/m |

/

|

±0.05 mm/m |

/

|

Maximum acceleration |

0.5G |

|||||

Application scenarios

Fiber laser cutting equipment is suitable for cutting metals, including stainless steel, low-carbon steel plates (tubes), carbon steel, alloy steel plates, spring steel, iron sheets, galvanized iron, galvanized steel sheets, aluminum plates, copper plates, brass plates, bronze plates, gold plates, silver plates, titanium plates, and various metal sheets, as well as tubes and pipes. The achievable cutting thickness varies depending on the specific laser power settings chosen for the sheet metal laser cutting machine.

ZCLASER

Shandong Zhancheng Intelligent Manufacturing Co., Ltd is a professional research, development, production andsales of laser cutting marking equipment company, can be tailored for differententerprises of various non-standard laser equipment. Companies and many large well-known enterprises at home and abroad to establish long- term stability ofhe interactive relations of cooperation, forthe majority of users with the perfect laser processing solutions and thecorresponding supporting facilities, widelyused in auto parts, instrument, measuring tool cutting tool, electronic communications, aerospace, petrochemical, military products, medicine, food,packaging, and various metal and non-metal material marking.and is a leading enterprise in the laser industry.

Qualifications

If you are interested in this product, please complete the following information submitted to us, we will arrange experts to contact you as soon as possible!

Related Products

Related Products

Floor 16, Building A, Rongsheng Times International, Licheng District, Jinan City, Shandong Province,China