ZCMini-HPT Automatic Platform Laser Welding Machine

A Laser Welding Machine is an advanced industrial equipment that utilizes a high-energy-density laser beam as a heat source to achieve precise, efficient, and high-quality welding of materials. It is a cornerstone technology in modern manufacturing, offering unparalleled accuracy, minimal heat distortion, and exceptional weld strength for a wide range of metals and alloys, including steel, aluminum, copper, and titanium.

- 产品描述

- parameter

-

- Brand: ZCLASER

- Commodity name: ZCMini-HPT Automatic Platform Laser Welding Machine

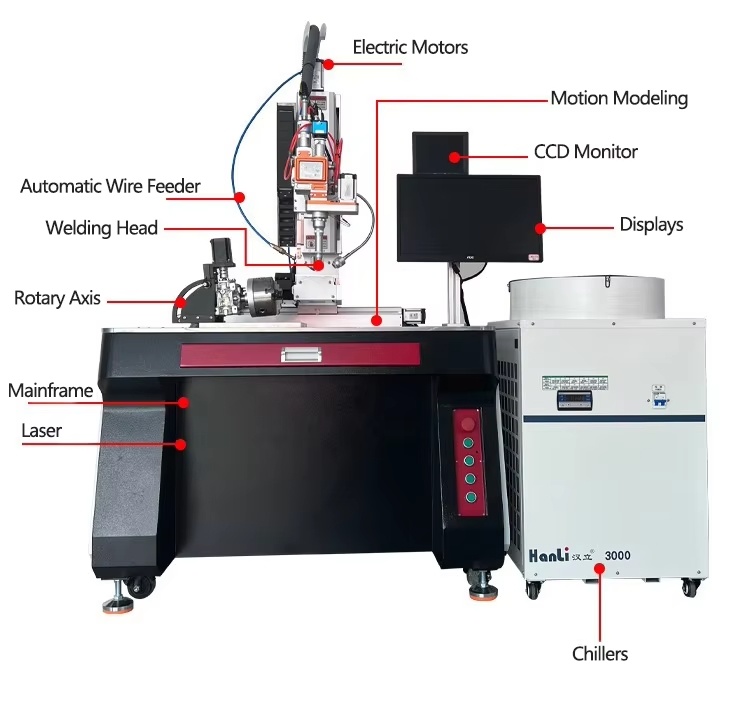

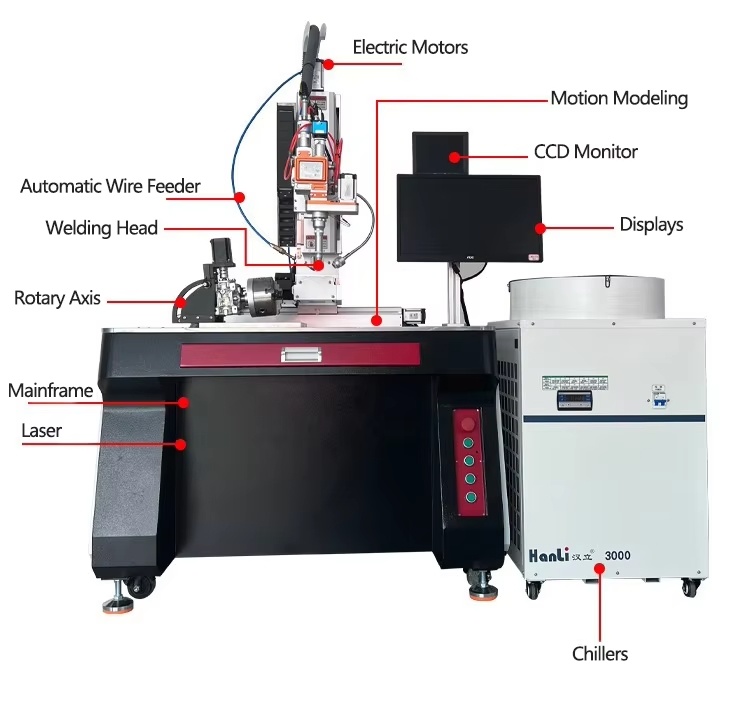

All-steel chrome-plated housing, fully automatic standard welding, with optional stepper/servo motors. Machine configuration and rotary fixtures can be selected according to precise machining requirements.

Metal Automatic Laser Welding Machine

1. This machine is equipped with a 1000W fiber laser, featuring high electro-optical conversion efficiency and an extended laser lifespan;

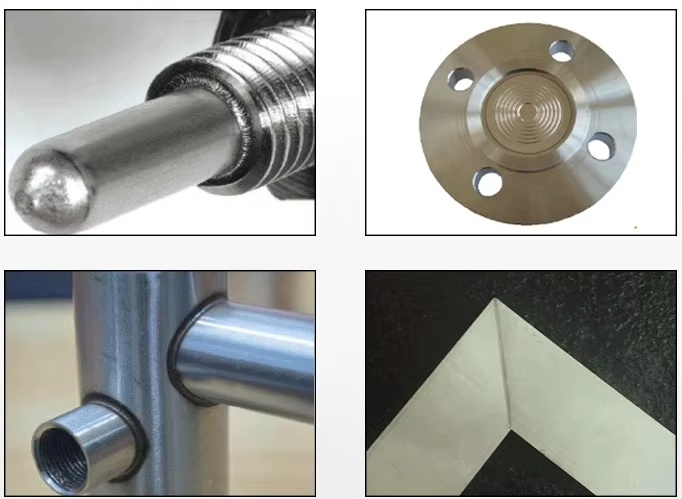

2. The laser beam boasts exceptional quality and enables welding at speeds more than five times faster than conventional fiber-optic laser welders, delivering outstanding welding results with deep weld seams, minimal taper, and high precision—perfectly meeting the diverse needs of users across various industries. The resulting welds are not only robust and durable but also smooth, aesthetically pleasing, and visually appealing.

3. The entire machine features low energy consumption, requires no maintenance, boasts high stability, and can help users significantly reduce processing costs over the long term.

4. The control system is a professional four-axis system specifically designed for laser welding. It features powerful PC-based control capabilities, making it easy to program, debug, and maintain. It supports protective, automatic, or semi-automatic spot welding, butt welding, lap welding, seam sealing, as well as welding of complex planar lines, arc paths, and any arbitrary trajectories—offering high stability, strong scalability, and effortless learning and operation.

5. Equipped with a large workbench, the platform features an XY dual-axis motor module, and the Z-axis is fitted with a power-off braking motor. It can also be equipped with a timed rotary axis, enabling 3D laser welding of irregularly shaped three-dimensional products—delivering fast speeds, extended durability, and high precision.

6. It supports time division or energy division, making it suitable for various processing applications, including multi-station machining. It can be widely used in both spot laser welding and continuous welding applications, as well as in the flexible manufacturing industry.

7. Customizable automated fixtures that can be combined with assembly lines, photoelectric sensors, pneumatic grippers, and more, enabling automated processing and mass production.

Industrial computer

Built-in CCD vision system allows real-time viewing of machine welding details, enabling multi-axis high-performance motion.

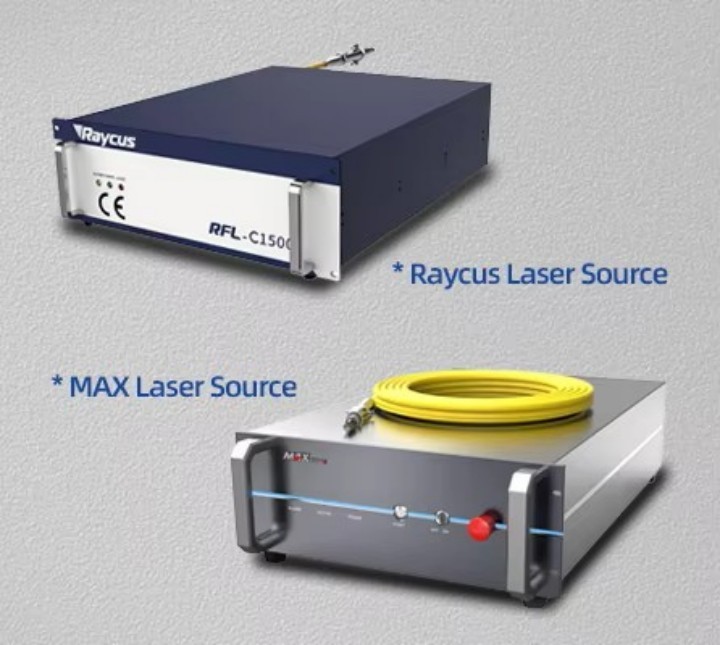

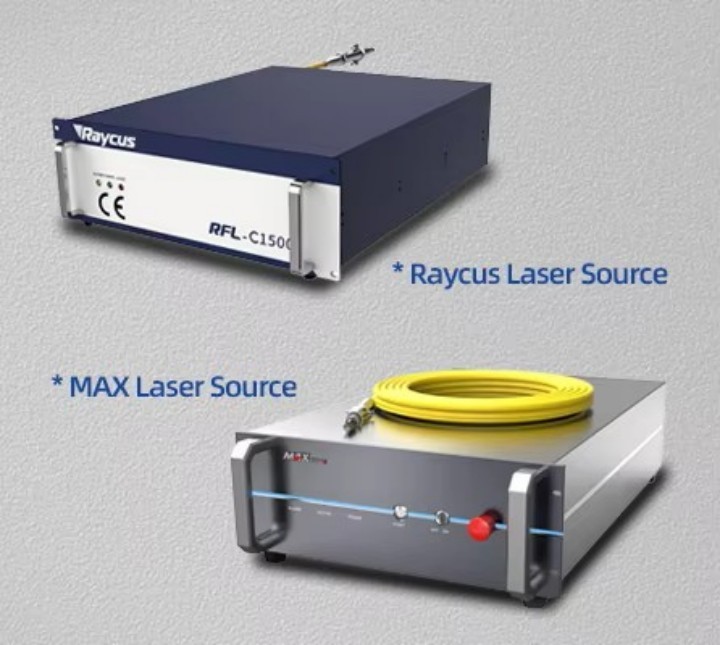

Optical fiber laser source

Utilizing renowned brands (such as Raycus, JPT, MAX, and IPG), the photoelectric conversion rate is significantly improved, laser power is enhanced, and welding performance is optimized. We can also customize configurations based on customer needs, ensuring satisfaction tailored to each client's requirements.

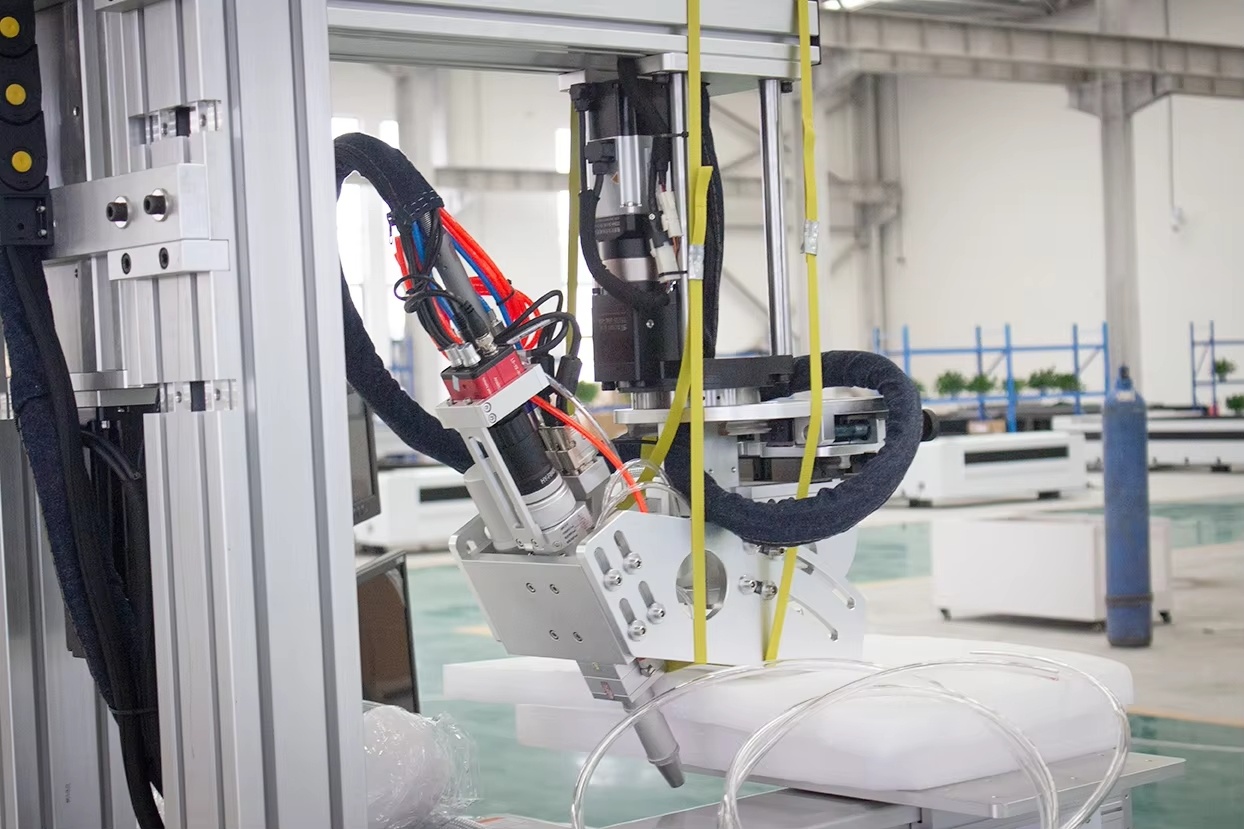

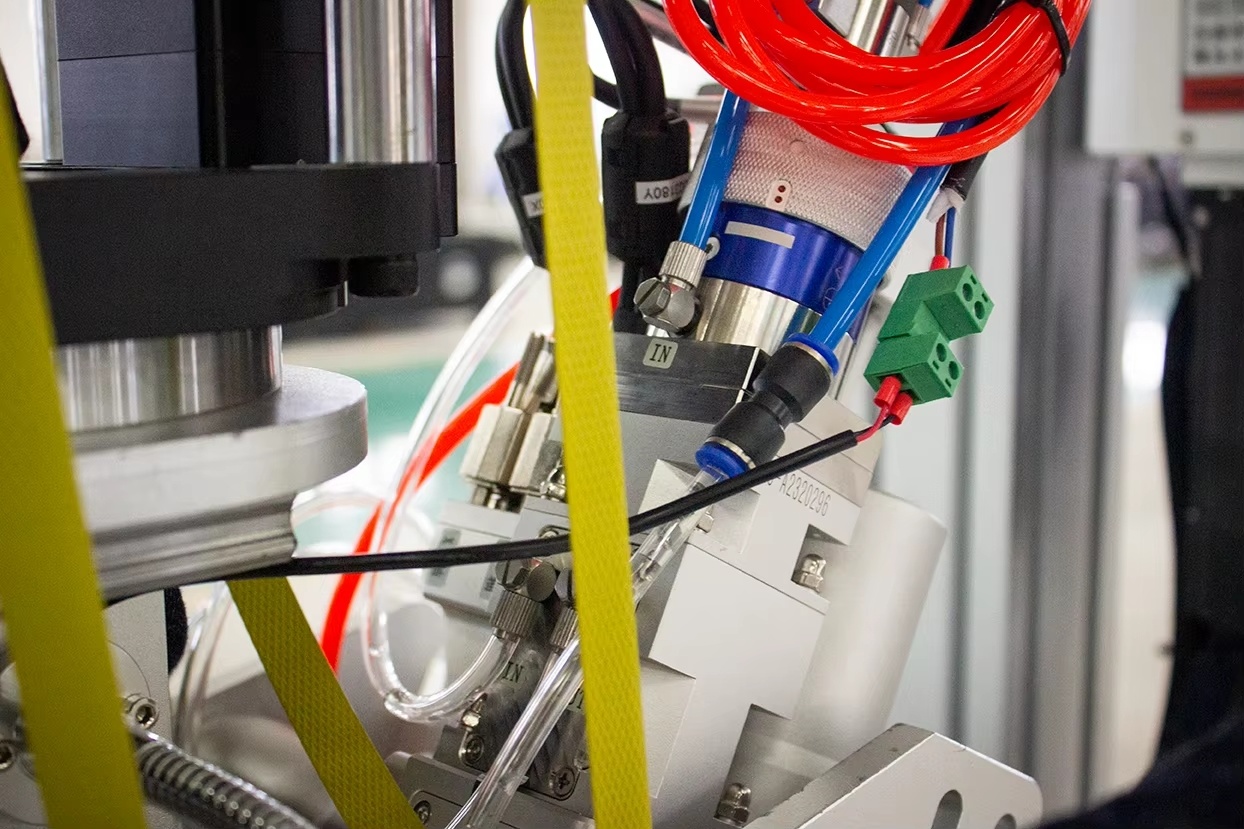

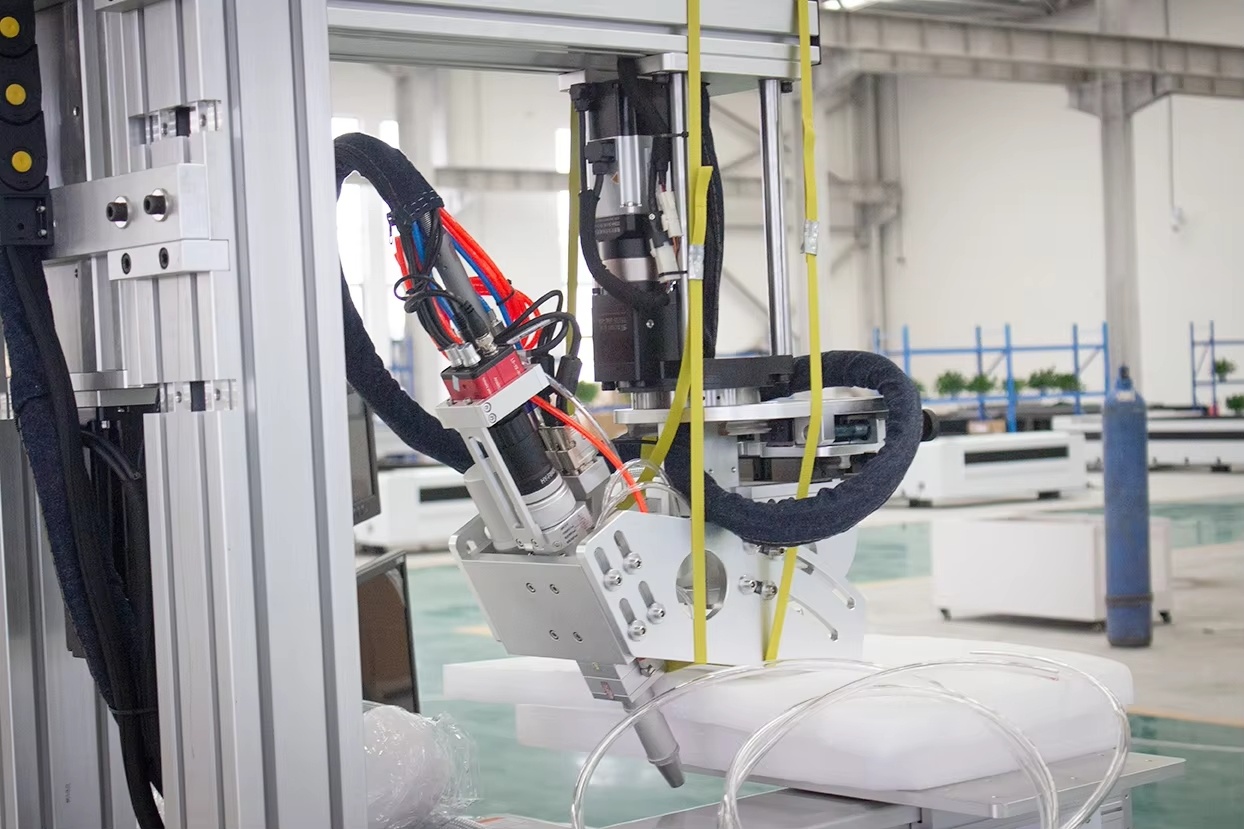

Robot welding arm

Introducing 3D automated processing, leveraging robotic arms for automatic welding—this reduces defect rates, saves labor, and lowers overall costs.

Water-cooled machine

Dual-temperature refrigerator with independent cooling for the laser and welding head, effectively safeguarding machine safety.

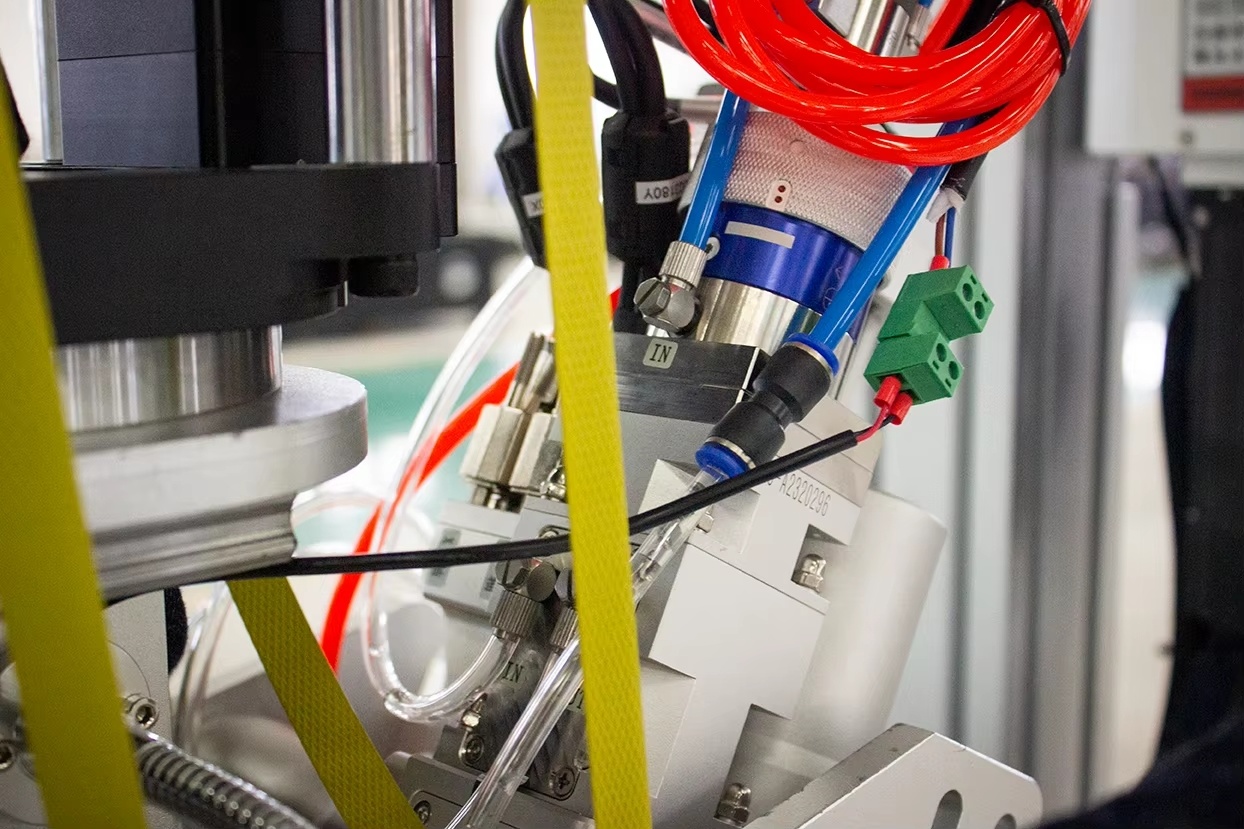

Laser Welding Head Automatic Focusing

Smart proximity, built-in sensor, automatic focus locking—saving operation time, one-click start for even simpler handling.

Integrated Control Switch

Integrated power control for convenient on/off operation.

Parameters

Laser power

1000w/1500w/2000w/3000w

Welding materials

Metal (welding thickness varies depending on the material)

Maximum Melting Width

5mm

Maximum Melting Depth

10mm

Laser wavelength

1064nm

Output power

10–100%

Welding Trajectory

Straight/Circular/Irregular Welding

Cooling Method

Water cooling

Light spot size

0.1-5mm

Laser source

JPT/max/RAYCUS/RECI

Effective Travel

450×300×400×100 (X×Y×Z×R) is customizable

Welding System

Automated Welding System (Programmable)

Software-supported formats

DWG/DFX/BMP/PCX/PLT

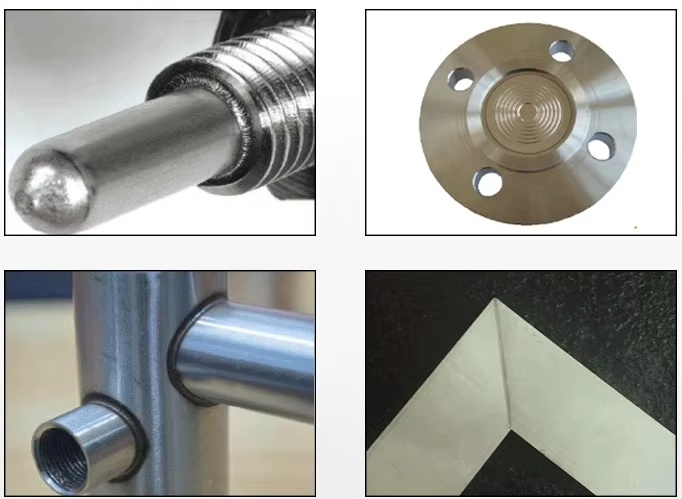

Application Scenarios

-

-

参数列表

- Brand: ZCLASER

- Model: ZCMini-HPT

- Price: $5,200~$5,620

- Delivery period: 1 unit/20 days

- Warranty period: 2 years warranty for core components, 3 years warranty for the whole machine

-

Keywords:

5axis Laser Welder Machine

Laser Welder Machine

Fiber Laser Welding Machine 100W

welding

laser

machine

fiber

Classification:

Product Description

Metal Automatic Laser Welding Machine

1. This machine is equipped with a 1000W fiber laser, featuring high electro-optical conversion efficiency and an extended laser lifespan;

2. The laser beam boasts exceptional quality and enables welding at speeds more than five times faster than conventional fiber-optic laser welders, delivering outstanding welding results with deep weld seams, minimal taper, and high precision—perfectly meeting the diverse needs of users across various industries. The resulting welds are not only robust and durable but also smooth, aesthetically pleasing, and visually appealing.

3. The entire machine features low energy consumption, requires no maintenance, boasts high stability, and can help users significantly reduce processing costs over the long term.

4. The control system is a professional four-axis system specifically designed for laser welding. It features powerful PC-based control capabilities, making it easy to program, debug, and maintain. It supports protective, automatic, or semi-automatic spot welding, butt welding, lap welding, seam sealing, as well as welding of complex planar lines, arc paths, and any arbitrary trajectories—offering high stability, strong scalability, and effortless learning and operation.

5. Equipped with a large workbench, the platform features an XY dual-axis motor module, and the Z-axis is fitted with a power-off braking motor. It can also be equipped with a timed rotary axis, enabling 3D laser welding of irregularly shaped three-dimensional products—delivering fast speeds, extended durability, and high precision.

6. It supports time division or energy division, making it suitable for various processing applications, including multi-station machining. It can be widely used in both spot laser welding and continuous welding applications, as well as in the flexible manufacturing industry.

7. Customizable automated fixtures that can be combined with assembly lines, photoelectric sensors, pneumatic grippers, and more, enabling automated processing and mass production.

Product Details

Industrial computer

Built-in CCD vision system allows real-time viewing of machine welding details, enabling multi-axis high-performance motion.

Optical fiber laser source

Utilizing renowned brands (such as Raycus, JPT, MAX, and IPG), the photoelectric conversion rate is significantly improved, laser power is enhanced, and welding performance is optimized. We can also customize configurations based on customer needs, ensuring satisfaction tailored to each client's requirements.

Robot welding arm

Introducing 3D automated processing, leveraging robotic arms for automatic welding—this reduces defect rates, saves labor, and lowers overall costs.

Water-cooled machine

Dual-temperature refrigerator with independent cooling for the laser and welding head, effectively safeguarding machine safety.

Laser Welding Head Automatic Focusing

Smart proximity, built-in sensor, automatic focus locking—saving operation time, one-click start for even simpler handling.

Integrated Control Switch

Integrated power control for convenient on/off operation.

Parameters

| Laser power |

1000w/1500w/2000w/3000w |

| Welding materials |

Metal (welding thickness varies depending on the material) |

| Maximum Melting Width

|

5mm |

| Maximum Melting Depth |

10mm |

| Laser wavelength |

1064nm |

| Output power |

10–100% |

| Welding Trajectory |

Straight/Circular/Irregular Welding |

| Cooling Method |

Water cooling |

| Light spot size |

0.1-5mm |

| Laser source |

JPT/max/RAYCUS/RECI |

| Effective Travel |

450×300×400×100 (X×Y×Z×R) is customizable |

| Welding System |

Automated Welding System (Programmable) |

| Software-supported formats |

DWG/DFX/BMP/PCX/PLT |

Application Scenarios

ZCLASER

Shandong Zhancheng Intelligent Manufacturing Co., Ltd is a professional research, development, production andsales of laser cutting marking equipment company, can be tailored for differententerprises of various non-standard laser equipment. Companies and many large well-known enterprises at home and abroad to establish long- term stability ofhe interactive relations of cooperation, forthe majority of users with the perfect laser processing solutions and thecorresponding supporting facilities, widelyused in auto parts, instrument, measuring tool cutting tool, electronic communications, aerospace, petrochemical, military products, medicine, food,packaging, and various metal and non-metal material marking.and is a leading enterprise in the laser industry.

A Laser Welding Machine is an advanced industrial equipment that utilizes a high-energy-density laser beam as a heat source to achieve precise, efficient, and high-quality welding of materials. It is a cornerstone technology in modern manufacturing, offering unparalleled accuracy, minimal heat distortion, and exceptional weld strength for a wide range of metals and alloys, including steel, aluminum, copper, and titanium.

Qualifications

If you are interested in this product, please complete the following information submitted to us, we will arrange experts to contact you as soon as possible!

Related Products

Related Products

Floor 16, Building A, Rongsheng Times International, Licheng District, Jinan City, Shandong Province,China