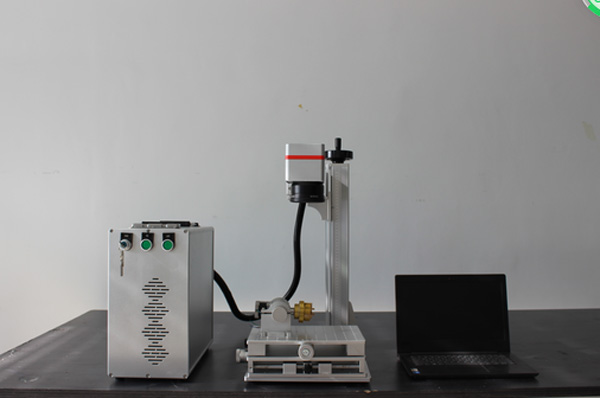

If the laser marking machine is operated in the cold winter, some precautions must be taken to ensure that the laser marking machine equipment is normal and the working environment meets the requirements before the marking operation can be carried out.

These items also refer to the maintenance of the laser marking machine.

1. Before turning on the acousto-optic power supply of the laser marking machine, check that there is sufficient pure water in the water-cooling circulation system, and turn it on first, otherwise the acousto-optic devices will be easily damaged. Operate according to the correct starting sequence of the marking machine.

2. In order not to damage the precision vibrating lens part, the external power supply must be well connected and protected.

3. Do a good job of dust prevention. Do not place the laser marking machine in dusty places. If it is contaminated, clean it up in time.

4. The place where the marking machine is operated must have a certain space and be kept clean.

5. If the marking machine fails during use, do not disassemble it without authorization, and contact the manufacturer of the marking machine to arrange for repair or door-to-door repair.

6. Control the circulating water temperature. The median value of the circulating temperature is set at 25 degrees and 28 degrees. If the temperature is higher than this temperature, the low temperature water should be replaced in time.

7. Ensure that the computer linked to the marking machine does not appear virus, and check and kill the virus every day.

8. Do a good job of waterproofing the marking machine.

9. The operating personnel must undergo professional training, and they do not recognize that it will cause man-made damage to the marking machine.

Post time: Nov-23-2021