The functions that 2D machines can achieve are marking, 2D engraving and deep engraving. The maximum thickness is about 2mm metal sheet cutting. Of course, you can manually adjust the focus to achieve greater thickness cutting, but this is a method, not a machine function, so let’s leave it alone. .

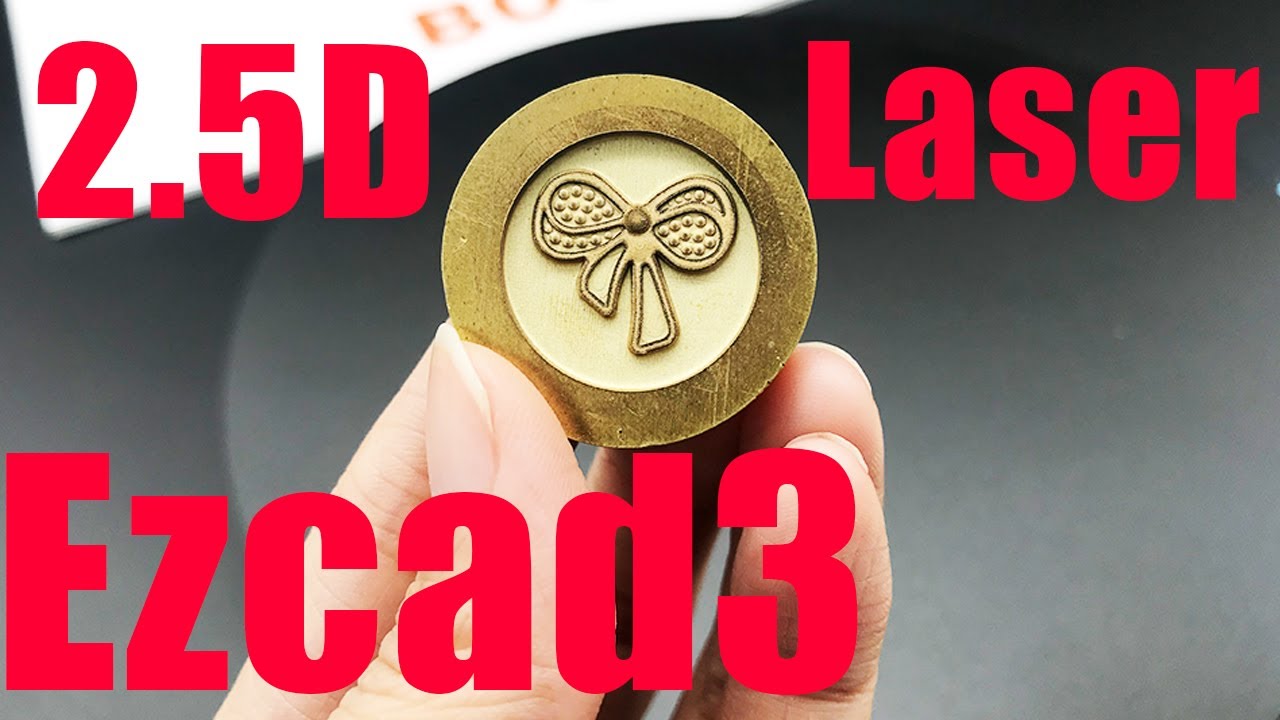

The 2.5D machine can realize the functions of marking, 2D, 3D engraving and relief, and theoretically larger thickness cutting (experiment is still needed, but the edge cutting effect is not required under the premise) depending on the height of the workpiece can be set to a fixed value At the same time, the focal length of the field lens of a single format is fixed, so to a certain extent, it is possible to realize a larger thickness cutting through the function setting in the software.

The functions that 3D machines can achieve are marking, 2D, 3D engraving and embossing. However, due to the influence of the field lens, I personally think that the cutting ability is weak and cannot realize the cutting of large thickness metal sheets. The more important advantage is the engraving, precision and effect. .

3D laser engraving machine also called 3D laser marking machine, 3D laser marker, 3D fiber laser engraving machine, it’s the most powerful laser engraving machine in market, so if you have several laser work to do, then choose 3D laser machine

If you just sample on engraving on flat surface, or rotary engraving, and no need 3d relief laser work, then choose 2D laser machine, in the same time, you want engraving 3d relief on flat surface, then choose 2.5D laser engraving machine.

Post time: Feb-21-2022