Laser marking has long been a fixed desktop installation. This constraint often requires dragging the part into the designated laser marking area and designing various devices to place the part under the static marking window.

When working with large or variable size parts, setup times increase, which can lead to costly downtime and loss of efficiency.

However, fiber laser marking technology has advanced and the area required has been reduced. Now you can deliver a portable fiber laser marking machine directly to your part, rather than the other way around, saving you time and money.

Before delving into this new advancement in portability, the first question is whether fiber laser marking technology is the best fit for your marking needs (as opposed to dot matrix, scribing, or other marking processes). Fiber lasers offer many advantages when it comes to marking. So when is fiber laser marking the right choice?

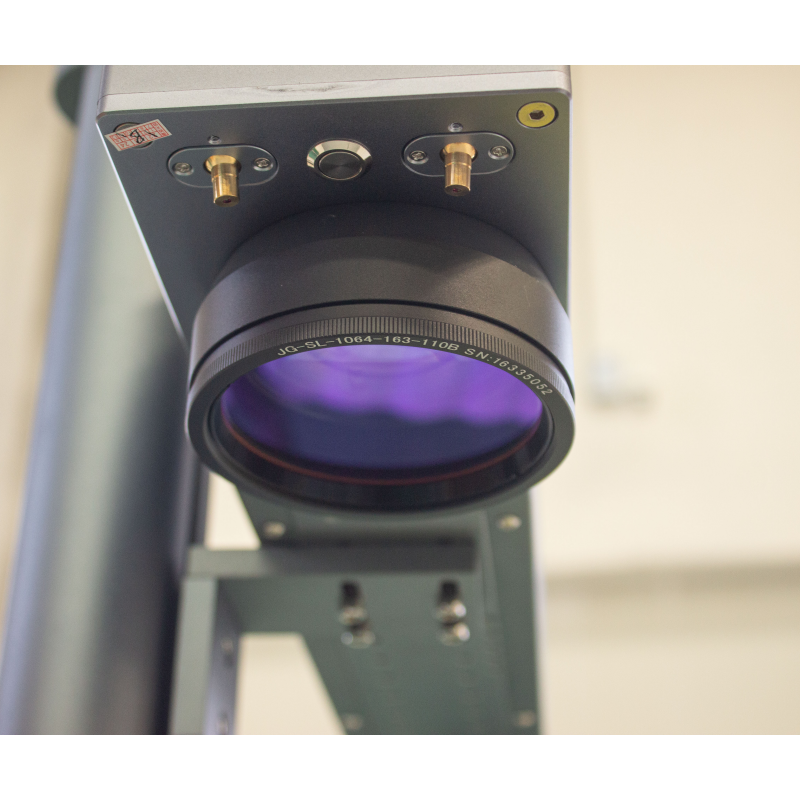

Overall, fiber laser marking is a reliable, reliable and reproducible permanent engraving method. First-generation technologies such as lamp and diode-pumped lasers have been replaced by high-performance fiber lasers that consume much less power. The fiber optic structure of the light source ensures extremely precise light distribution. This creates a small, well-defined laser beam, in which energy is mainly concentrated at a central point without power dissipation, allowing even the smallest workpieces to be marked with high resolution. The high power density of the laser beam also enables faster marking speeds than older laser technologies.

Fiber lasers are air-cooled and require minimal maintenance, for example older water-cooled laser systems often require lamp or filter replacement. In addition, fiber laser sources are designed to last nearly 100,000 hours. Since fiber lasers do not require constant alignment or adjustment of the optics, the setup time is also short. Fiber lasers are essentially plug and play machines requiring only three key settings (power, speed and frequency).

Fiber lasers can quickly mark a variety of metals, including steel, aluminum, copper, and more. Their wavelength is shorter than CO2 lasers but longer than UV lasers, allowing them to mark most industrial materials. However, CO2 laser marking technology is required to achieve the best results for certain materials such as certain resins, wood and glass.

Fiber lasers can produce complex and detailed marks, including logos, images, and barcodes, as well as the more standard alphanumeric characters commonly used in serialization. Once the settings have been optimized for compatible media, the markings are usually very noticeable.

Beyond the content and appearance of the marking, the choice between fiber laser and other marking methods such as dot and scribing usually comes down to the desired marking depth. Surface-level marks produced by fiber lasers typically do not pierce the substrate in the same way that dot and dash marks do, a feature that may be required in industries such as the food and aerospace industries, where indentation of materials is sometimes limited. However, if desired, higher power fiber lasers and multiple passes over the same area can be used to penetrate the surface. In addition, for steel processing such as galvanizing and powder coating, fiber laser marking is usually only used for marking after steel processing, while point hardening and scribing can create deep permanent marks that can be preserved during processing.

Once you have determined that fiber laser marking is suitable, the next question is how to use it most effectively. A lot can be done with a portable fiber laser machine that is not limited to a fixed installation.

Fiber lasers can produce complex and detailed marks, including logos, images, and barcodes, as well as the more standard alphanumeric characters commonly used in serialization. These markings are usually very obvious once the setup is optimized for a compatible substrate, be it steel, stainless steel, aluminum (anodized or otherwise), copper, etc.

What parts need to be marked? How many? What are their sizes? If an application requires repetitive marking of a large number of small parts, a stationary fiber laser may be the right choice. In addition, stationary machines are also worth considering if automation is required. However, if multiple parts are scattered throughout the plant, if the parts are large, difficult to move, or inefficient, or if your manufacturing process could benefit from marking on the go or at different locations on site, a portable fiber laser marking machine may be the right choice.

A portable fiber laser marking machine must include several key features for optimal marking results. First, the package must be a lightweight all-in-one device that can be easily carried or moved around the facility.

In addition, the power of the laser source should be sufficient to quickly obtain industrial strength marks, usually at least 20–30 W.

From a hardware point of view, the device should have a housing containing a laser source, a built-in PC and a lightweight handheld applicator connected to the laser source with an industrial cable. The design of the applicator allows easy and consistent marking from the same distance, ensuring correct alignment and focus. One or more holders can also be attached to the applicator for positioning and marking at different angles. These brackets additionally support reproducible and fast marking at the same focal length.

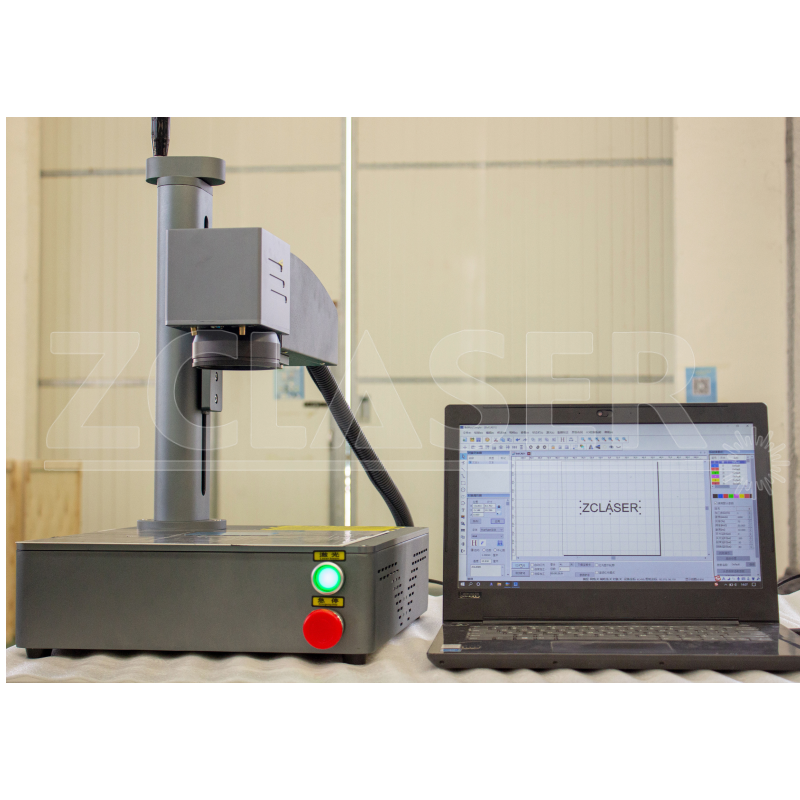

The PC of the unit must be built-in and equipped with software that allows you to quickly program the various flags of the unit itself and transfer them via the USB interface. The software package should also include preloaded settings such as speed, power and focal length for marking different materials. This will facilitate a quick transition from marking on one type of material to another.

The laser pointer is an important feature for correct positioning and analog marking. After modeling is complete, marking is usually initiated by pulling the trigger on the hand applicator. Alternatively, once the applicator is in place, the labeling process can often be initiated directly through the software without the use of a trigger.

Finally, a portable fiber laser marking machine must be flexible. For example, one of the optional accessories is a laser stand that allows you to easily switch from portable to stationary marking. This hybrid marking feature is ideal when you need to mark large parts that benefit from portability, as well as small repetitive parts that are best placed under a stand.

Other possible accessories include different cases and screens around the marked area, whether it’s for extra precautions in addition to the laser goggles or depending on the user’s preference. For even greater mobility, battery-powered technology is now available to completely detach the laser marking on the go, even outdoors.

With the advent of mobility, you can realize new time and cost savings as fiber laser marking can now be done virtually anywhere.

FABRICATOR is North America’s leading steel fabrication and forming magazine. The magazine publishes news, technical articles and success stories that enable manufacturers to do their job more efficiently. FABRICATOR has been in the industry since 1970.

Full digital access to The FABRICATOR is now available, providing easy access to valuable industry resources.

Full digital access to The Tube & Pipe Journal is now available, providing easy access to valuable industry resources.

Get full digital access to the STAMPING Journal, featuring the latest technology, best practices and industry news for the metal stamping market.

Full access to The Fabricator en Español digital edition is now available, providing easy access to valuable industry resources.

Brothers Rob and Anthony DiVito of Chicago-based furniture designer and manufacturer iRcustom join us to discuss more…

Post time: Mar-10-2023