Multi-Functional handheld Fiber Laser Welding Machine

- 产品描述

- parameter

-

- Brand: ZCLASER

- Commodity name: Multi-Functional handheld Fiber Laser Welding Machine

1000w 1500w 2000w Hand Held Fiber Laser Cleaning Machine Rust Oil Painting Surface Laser Cleaner Cleaning Machine

Features

1.Easy operating need no training.

2.Fiber Laser welding can be used in welding stainless steel, aluminum, copper, chromium, nickel, titanium and other metals or alloys.

3.Welding range: 0.5~8 mm carbon steel, 0.5~4 mm stainless steel, aluminium alloy 0.5~6 mm, brass 0.5~4 mm.

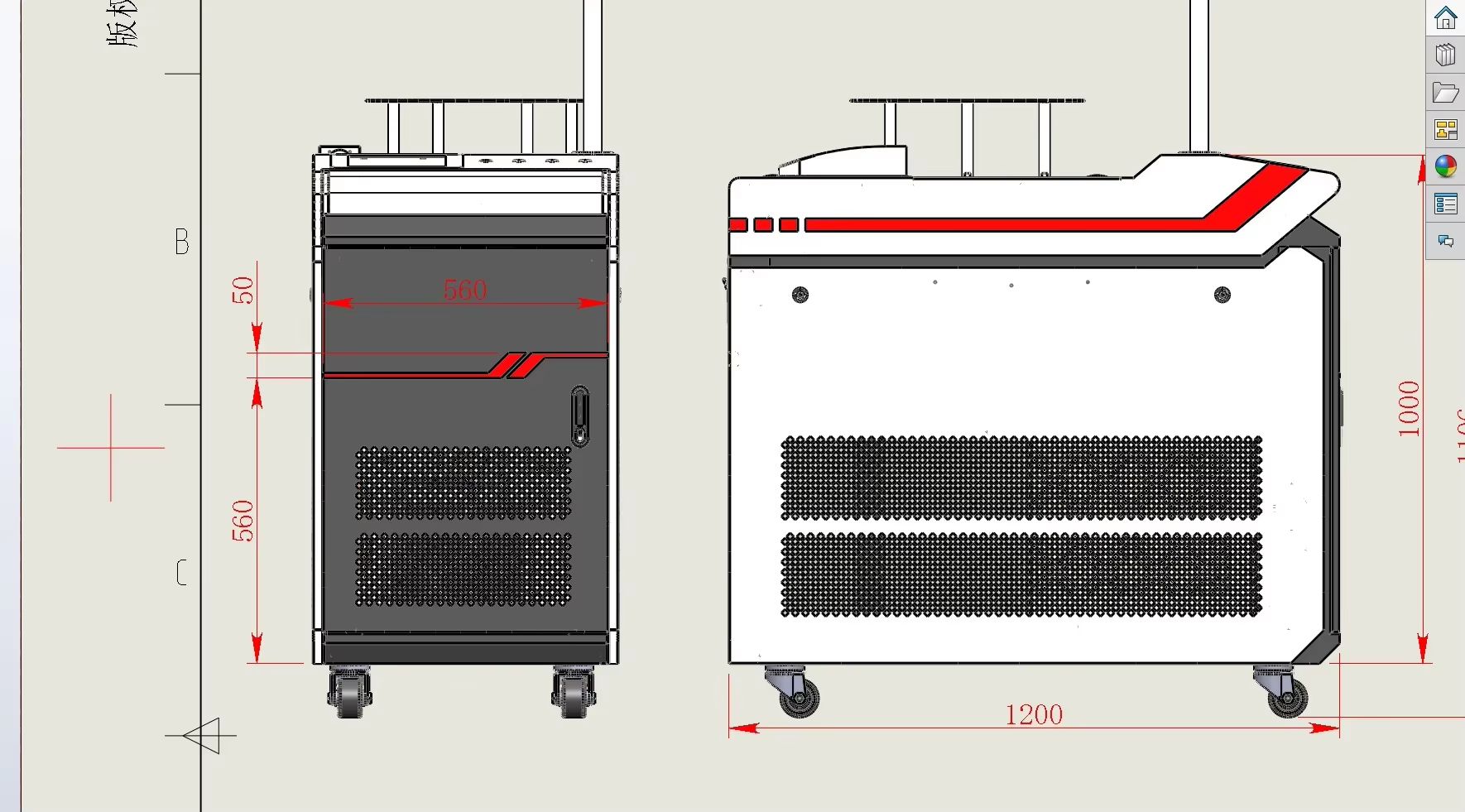

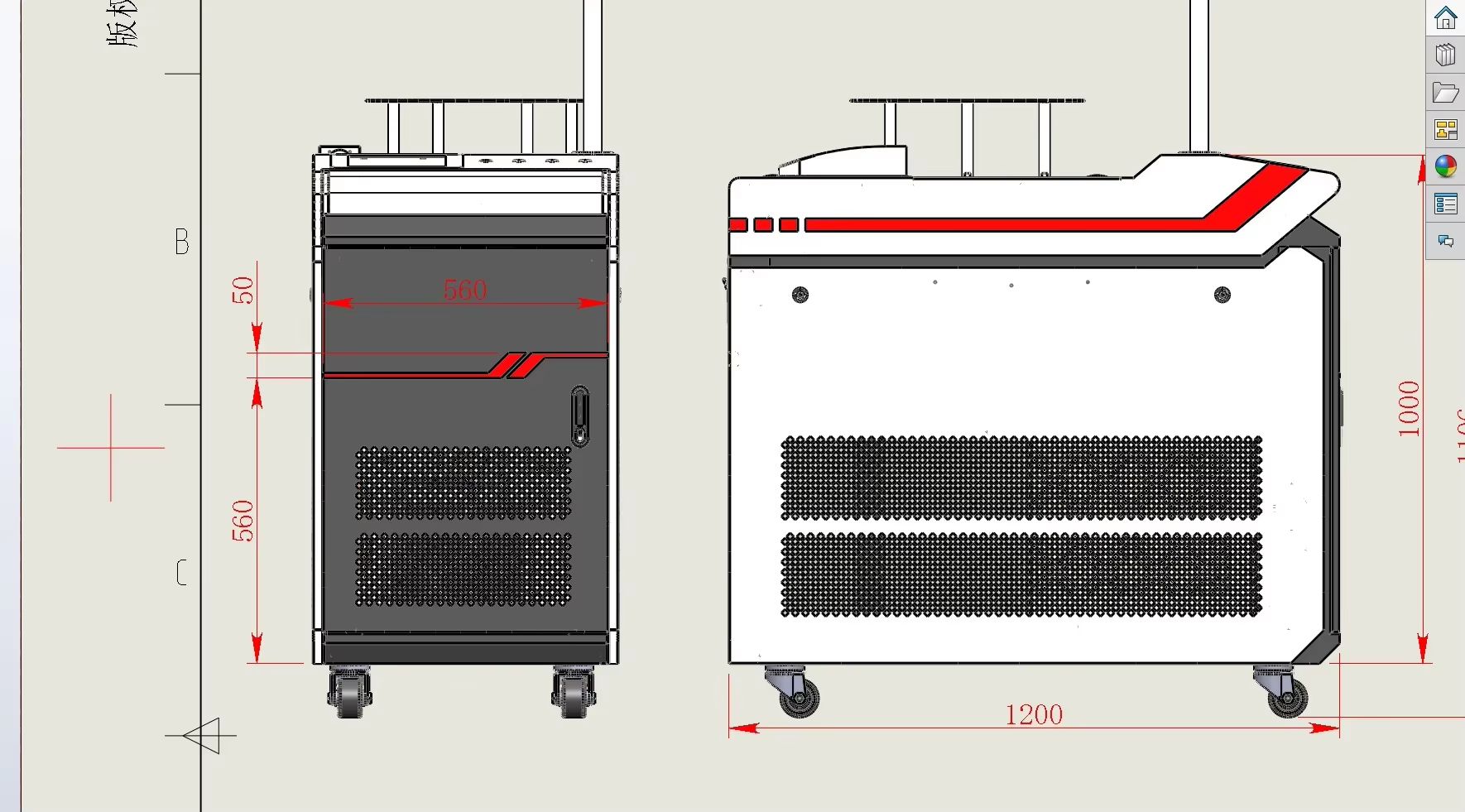

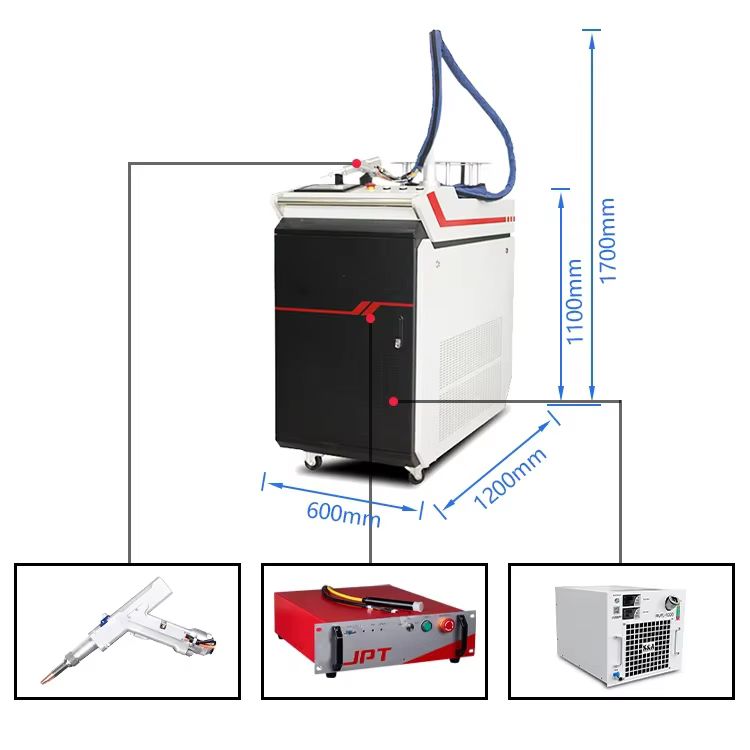

4.Easy to move, Push-pull handle.

5.Welding seam beautiful smooth and beautiful, don’t need polish, save your time.

6.Stable performance, Universal casters, Easy to operate.

7.Laser welding has less consumables and long service life.

8.Safer, more environmentally friendly.

9.The replacement rate is small, which greatly saves labor costs, maintenance costs and equipment costs.

10.The machine has wheels, easy to move anywhere in factory you need.

Product Details

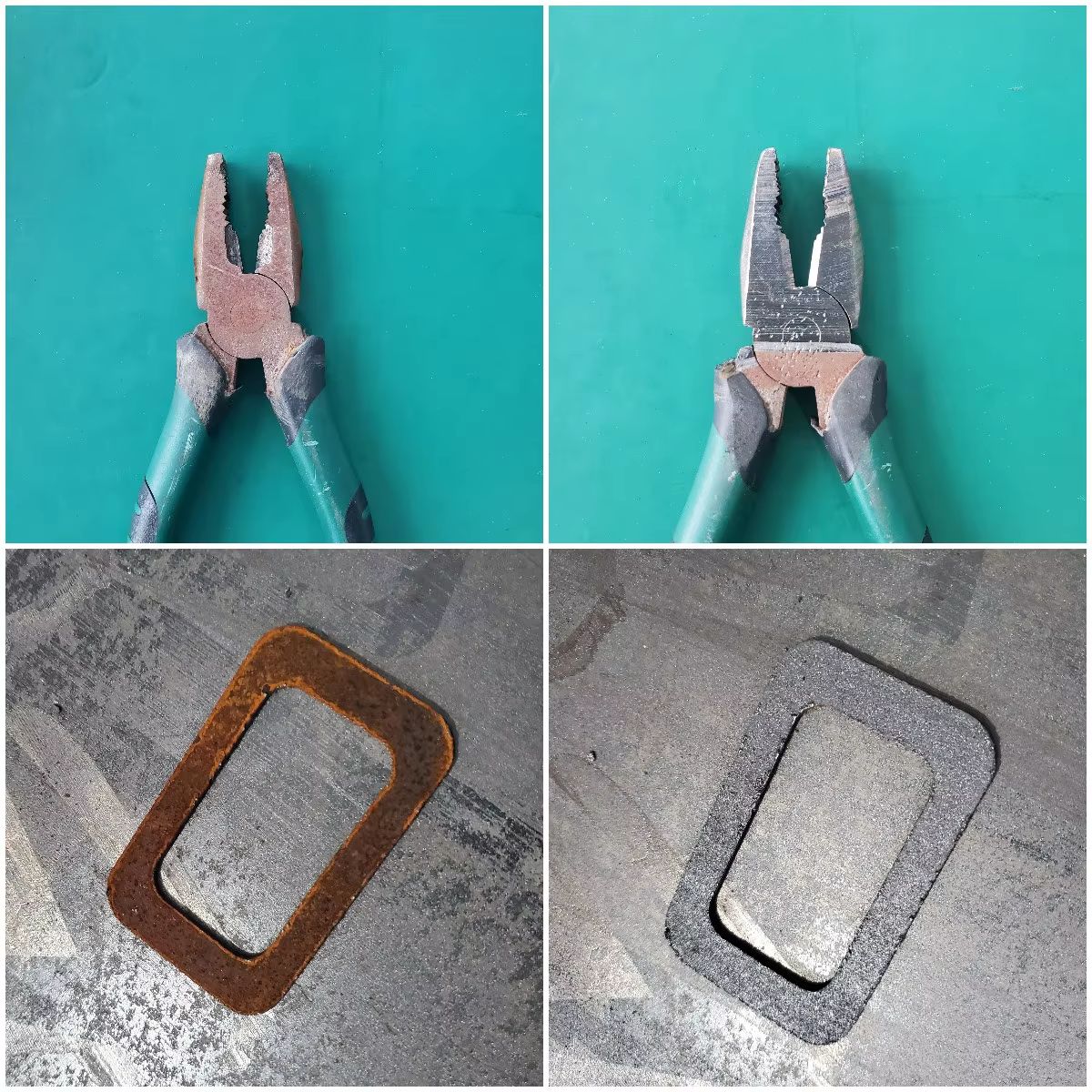

Why You Choose A Laser Welding Machine Rather Than A Traditional One?

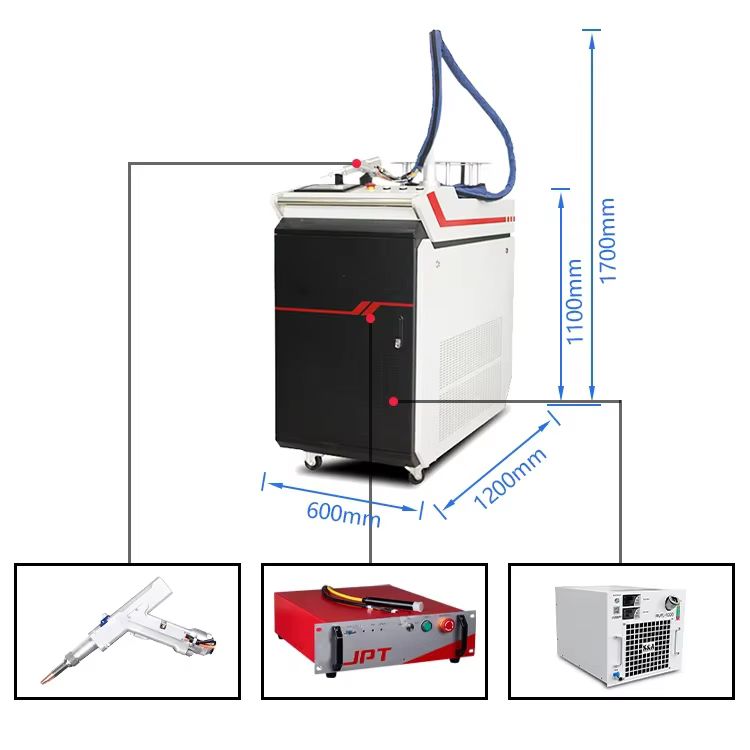

The hand-held laser welding machine replaces the previous fixed optical path with a hand-held welding gun. Hand-held welding is flexible and convenient, the welding distance is longer, and it overcomes the limitations of the workbench space. Mainly for large workpieces, fixed positions such as inner right angle, outer right angle, flat surface welding, small heat affected area during welding, small deformation, large welding depth, and firm welding. It is a new and more flexible welding process for long distance welding of large workpieces.

HANLI water cooler

1. Environmentally friendly refrigerant can be selected;

2. Temperature control accuracy reaches ±0.3℃;

3. It has two temperature control modes, suitable for different use occasions; it has a variety of settings and fault display functions.

4. It has a variety of alarm protection functions: compressor delay protection; compressor overcurrent protection; water flow alarm; ultra-high/low temperature alarm;

5. Stable refrigeration and easy operation;

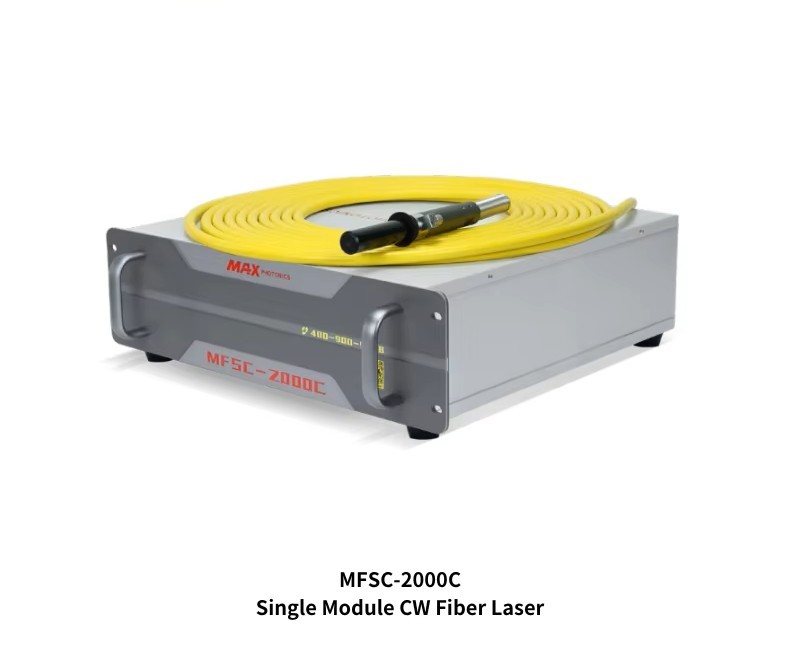

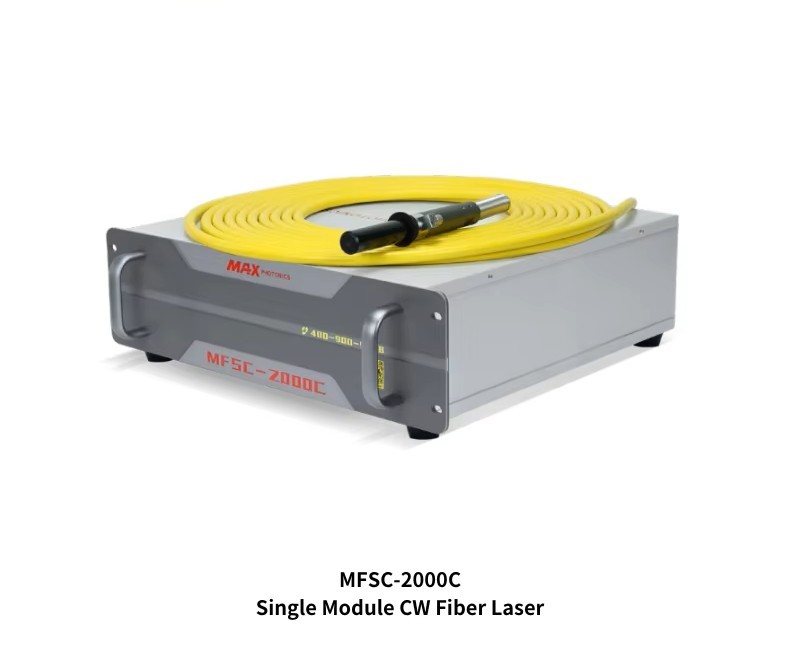

MAX 2000C, the latest welding/cleaning dedicated laser source

Single-mode continuous fiber laser is an optimized combination of optical , mechanical , electrical and soft .Through the control interface and standard software , the laser's operating status can be monitored and alarmed in real time . with one-year global warranty time ,we bear the round-ship cost .

Automatic Wire Feeder

The wire can be automatically fed through the wire feeder equipment ,which facilitates continuous welding and saves labor costs , high effiency welding working for you .

LASER NOZZLE & PARTS

Full sets nozzle , welding & cutting & cleaning nozzle along with the machine ,protective lens , protective glasses and all the tools in the package.

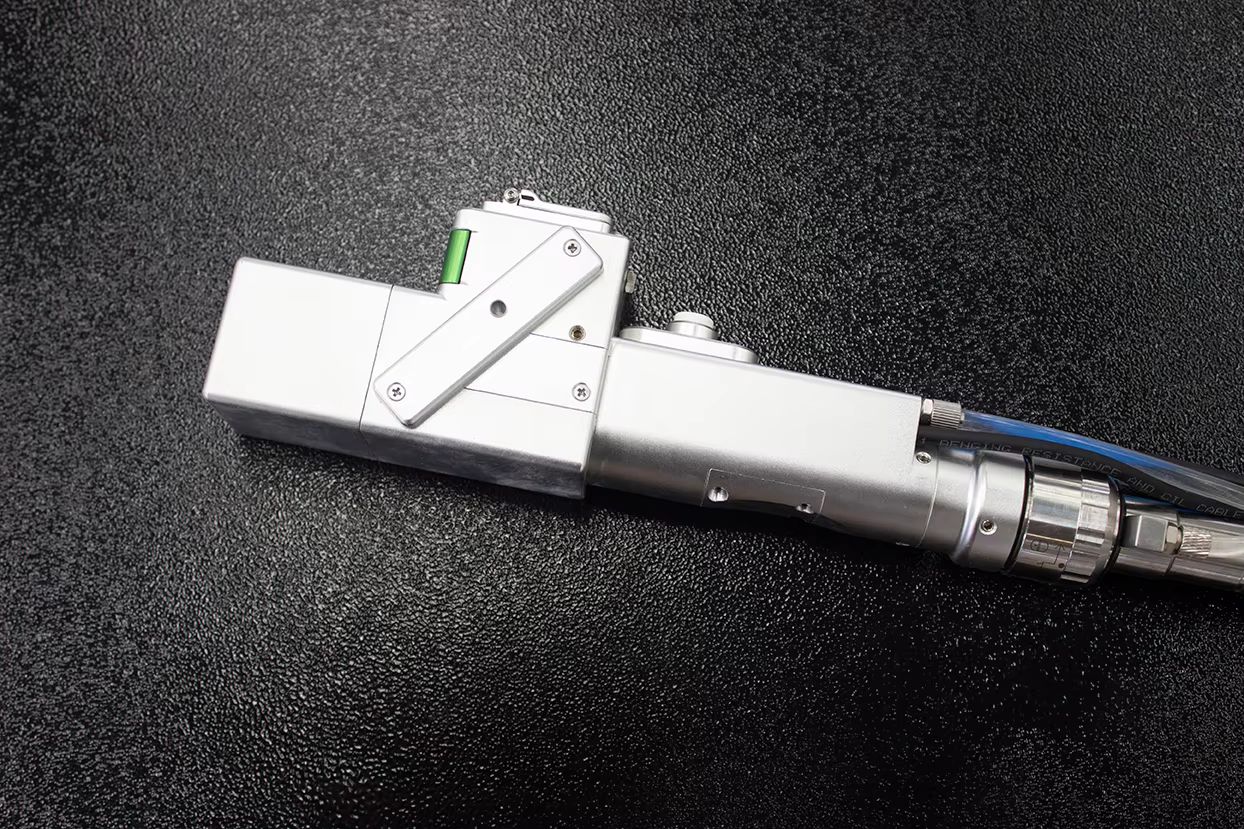

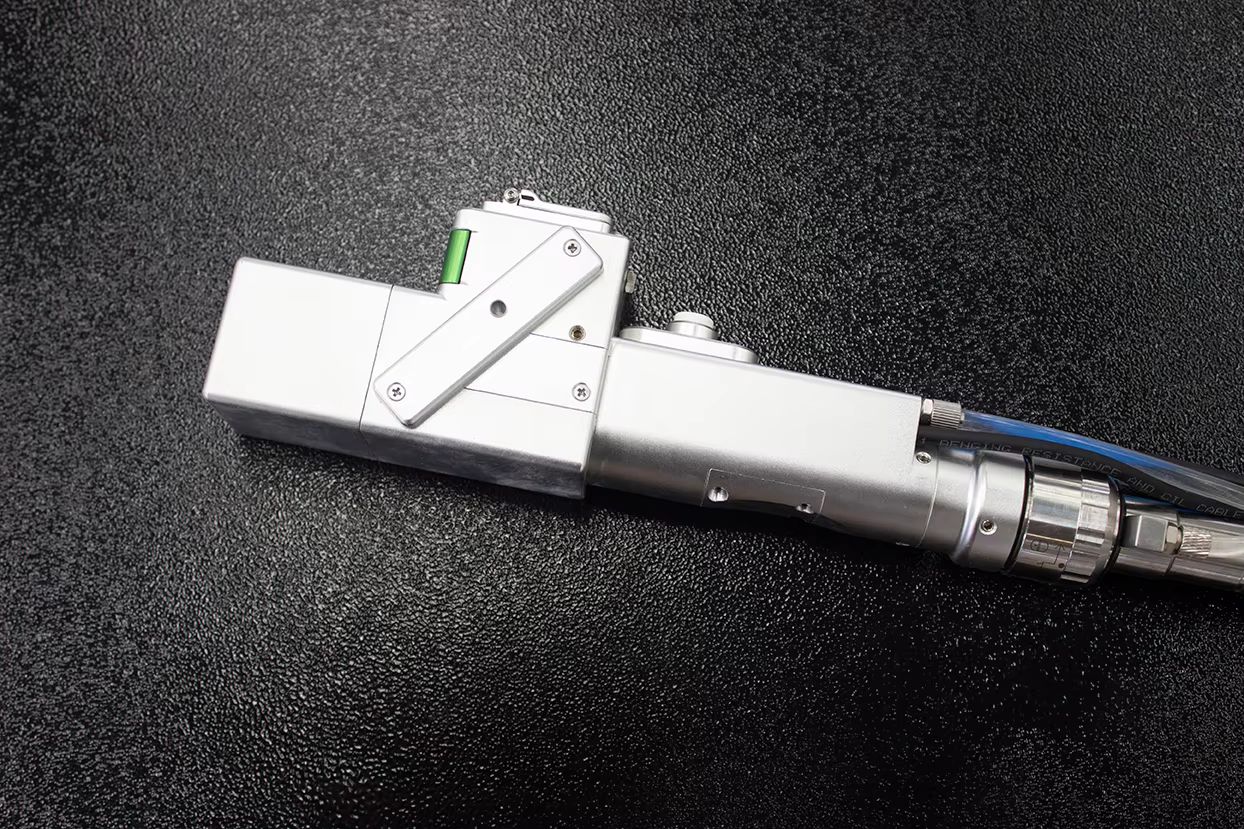

LASER WELDING HEAD

Functional application, can switch between welding, cutting and cleaning.Intelligent protection system, mobile terminal APP and PC monitoring, real-time feedback of working status.High-threshold optical components and better welding effect.Multiple safety locks, high safety performance.The whole body is designed with water cooling, and the stability is more durable.Ergonomic design, comfortable to hold and easy to grasp.

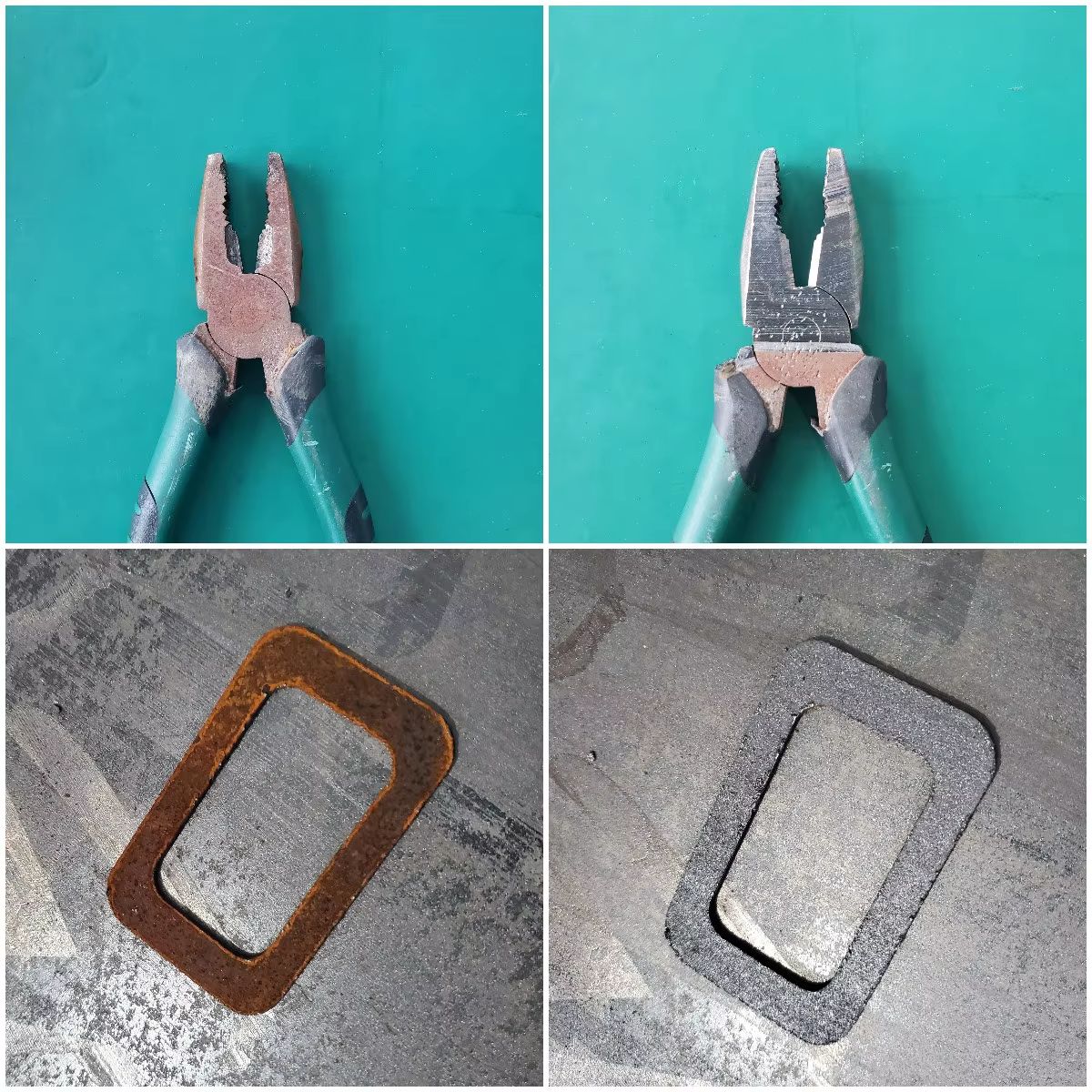

LASER CLEANING HEAD

Cleaning width can be 2cm-3cm with 150mm focus lens ,to achieve 5cm-7cm cleaning width , can add a 400mm focus lens module , it can be customized by our customer .

Product Parameters

Name

Automatic Laser Welding Machine

Output Power

1000W / 1500W/2000W/3000w

Usage

Metal Welding

Pulse Width

0.5-20ms

Fiber Length

8~10 Meters

Wavelength

1080nm

Cooling System

Water Cooling

Laser Head Brand

WSX

Cooling Machine

S&A Water Chiller

Laser Source

JPT/ MAX/ RAYCUS/ RECI

Welding Mode

Manual Handheld

Type

Laser Welding √√√

Solid YAG

Traditional Weding

Welding Quality

Heat input

Small

Small

Big

Deformation

Small

Small

Big

Welding shape

Smooth

Fish-scale pattern

Fish-scale pattern

Subsequent processing

No Need

Need to be polished

Need to be polished

Use operation

Welding speed

High

Medium

Low

Difficulty of welding

Easy

Medium

High

Safety and environmental friendly

Personal hazard

Small

Small

Big

Environmental pollution

Small

Small

Big

Cost Of Using

Consumables

No consumables

Laser crystal;

Xenon lampWelding rod

Energy consumption

Small

Big

Small

Welder requirements

No consumables

Normal

Experienced

Land area

Small

Big

Small

Application Scenarios

-

-

参数列表

- Brand: ZCLASER

- Model: HANDHELD LASERWELDING MACHINE

- Price: $2,899~$2,999

- Delivery period: 1 unit/10 days

- Warranty period: 2 years warranty for core components, 3 years warranty for the whole machine

-

Keywords:

Laser Welding Machine

Laser Cleaning Machine

Laser Cutting Machine

Hand Held Fiber Laser Cleaning Machine

Classification:

Product Description

Features

1.Easy operating need no training.

2.Fiber Laser welding can be used in welding stainless steel, aluminum, copper, chromium, nickel, titanium and other metals or alloys.

3.Welding range: 0.5~8 mm carbon steel, 0.5~4 mm stainless steel, aluminium alloy 0.5~6 mm, brass 0.5~4 mm.

4.Easy to move, Push-pull handle.

5.Welding seam beautiful smooth and beautiful, don’t need polish, save your time.

6.Stable performance, Universal casters, Easy to operate.

7.Laser welding has less consumables and long service life.

8.Safer, more environmentally friendly.

9.The replacement rate is small, which greatly saves labor costs, maintenance costs and equipment costs.

10.The machine has wheels, easy to move anywhere in factory you need.

Product Details

Why You Choose A Laser Welding Machine Rather Than A Traditional One?

The hand-held laser welding machine replaces the previous fixed optical path with a hand-held welding gun. Hand-held welding is flexible and convenient, the welding distance is longer, and it overcomes the limitations of the workbench space. Mainly for large workpieces, fixed positions such as inner right angle, outer right angle, flat surface welding, small heat affected area during welding, small deformation, large welding depth, and firm welding. It is a new and more flexible welding process for long distance welding of large workpieces.

HANLI water cooler

1. Environmentally friendly refrigerant can be selected;

2. Temperature control accuracy reaches ±0.3℃;

3. It has two temperature control modes, suitable for different use occasions; it has a variety of settings and fault display functions.

4. It has a variety of alarm protection functions: compressor delay protection; compressor overcurrent protection; water flow alarm; ultra-high/low temperature alarm;

5. Stable refrigeration and easy operation;

MAX 2000C, the latest welding/cleaning dedicated laser source

Single-mode continuous fiber laser is an optimized combination of optical , mechanical , electrical and soft .Through the control interface and standard software , the laser's operating status can be monitored and alarmed in real time . with one-year global warranty time ,we bear the round-ship cost .

Automatic Wire Feeder

The wire can be automatically fed through the wire feeder equipment ,which facilitates continuous welding and saves labor costs , high effiency welding working for you .

LASER NOZZLE & PARTS

Full sets nozzle , welding & cutting & cleaning nozzle along with the machine ,protective lens , protective glasses and all the tools in the package.

LASER WELDING HEAD

Functional application, can switch between welding, cutting and cleaning.Intelligent protection system, mobile terminal APP and PC monitoring, real-time feedback of working status.High-threshold optical components and better welding effect.Multiple safety locks, high safety performance.The whole body is designed with water cooling, and the stability is more durable.Ergonomic design, comfortable to hold and easy to grasp.

LASER CLEANING HEAD

Cleaning width can be 2cm-3cm with 150mm focus lens ,to achieve 5cm-7cm cleaning width , can add a 400mm focus lens module , it can be customized by our customer .

Product Parameters

Name | Automatic Laser Welding Machine |

Output Power | 1000W / 1500W/2000W/3000w |

Usage | Metal Welding |

Pulse Width | 0.5-20ms |

Fiber Length | 8~10 Meters |

Wavelength | 1080nm |

Cooling System | Water Cooling |

Laser Head Brand | WSX |

Cooling Machine | S&A Water Chiller |

Laser Source | JPT/ MAX/ RAYCUS/ RECI |

Welding Mode | Manual Handheld |

Type | Laser Welding √√√ | Solid YAG | Traditional Weding | |

Welding Quality | Heat input | Small | Small | Big |

Deformation | Small | Small | Big | |

Welding shape | Smooth | Fish-scale pattern | Fish-scale pattern | |

Subsequent processing | No Need | Need to be polished | Need to be polished | |

Use operation | Welding speed | High | Medium | Low |

Difficulty of welding | Easy | Medium | High | |

Safety and environmental friendly | Personal hazard | Small | Small | Big |

Environmental pollution | Small | Small | Big | |

Cost Of Using | Consumables | No consumables | Laser crystal; | Welding rod |

Energy consumption | Small | Big | Small | |

Welder requirements | No consumables | Normal | Experienced | |

Land area | Small | Big | Small | |

Application Scenarios

ZCLASER

Shandong Zhancheng Intelligent Manufacturing Co., Ltd is a professional research, development, production andsales of laser cutting marking equipment company, can be tailored for differententerprises of various non-standard laser equipment. Companies and many large well-known enterprises at home and abroad to establish long- term stability ofhe interactive relations of cooperation, forthe majority of users with the perfect laser processing solutions and thecorresponding supporting facilities, widelyused in auto parts, instrument, measuring tool cutting tool, electronic communications, aerospace, petrochemical, military products, medicine, food,packaging, and various metal and non-metal material marking.and is a leading enterprise in the laser industry.

Qualifications

If you are interested in this product, please complete the following information submitted to us, we will arrange experts to contact you as soon as possible!

Related Products

Related Products

Floor 16, Building A, Rongsheng Times International, Licheng District, Jinan City, Shandong Province,China