3 in 1 Fiber Laser Cleaning Machine

- 产品描述

- parameter

-

- Brand: ZCLASER

- Commodity name: 3 in 1 Fiber Laser Cleaning Machine

This product with 1500W-3000W fiber laser, handheld head, and water cooling features ergonomic design, safety alarm, and timing function for rental, enabling fast non-contact rust/paint removal on stainless steel/carbon steel etc., suitable for industrial cleaning.

Features

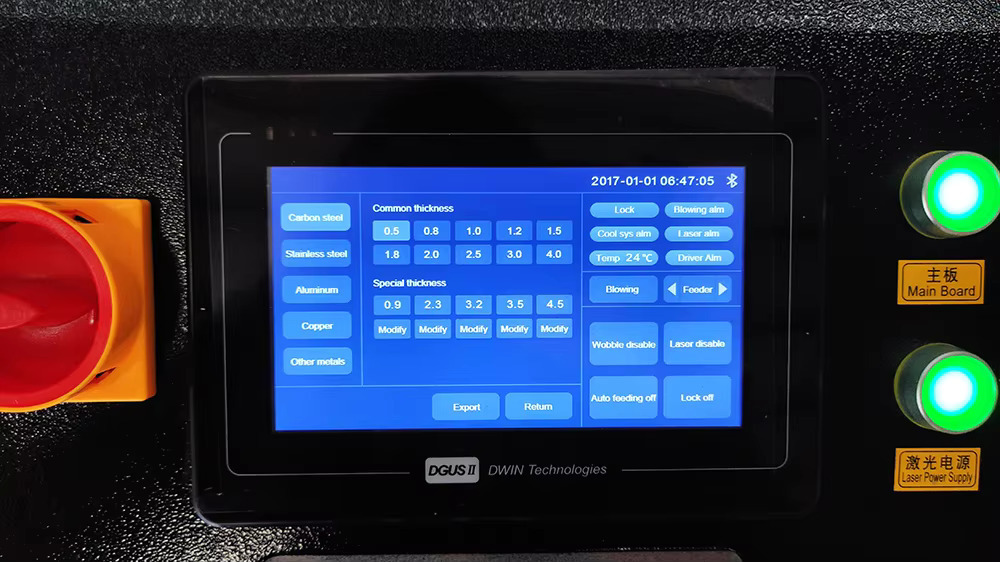

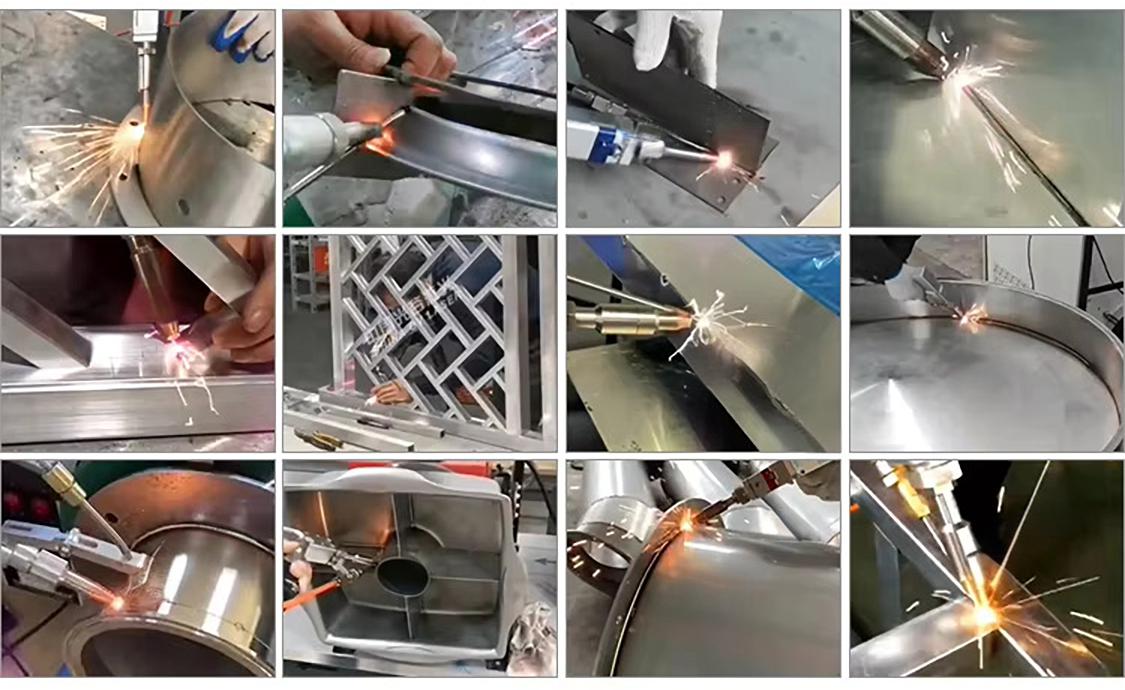

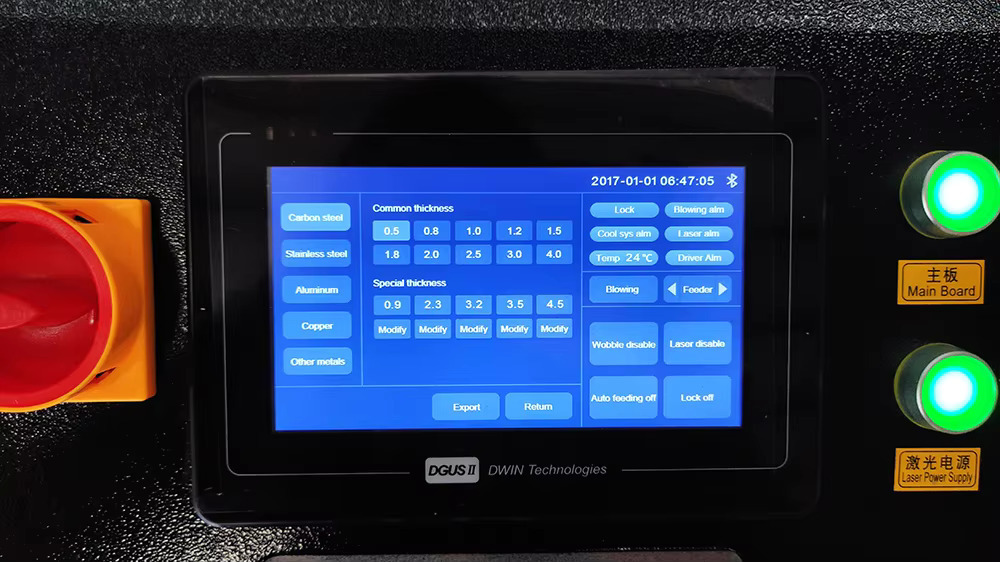

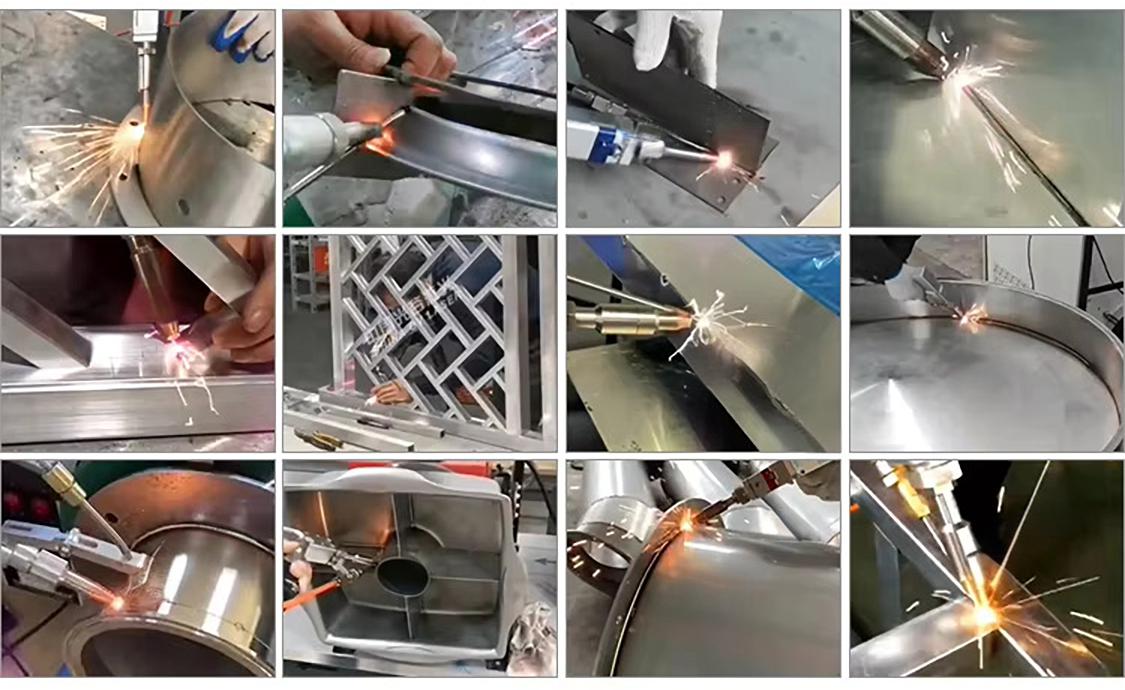

This product is mainly composed of laser source, handheld cleaning head, control panel, cabinet, etc. The cleaning system uses fiber laser, with fiber transmission, and after the fiber output is focused, it passes through a high-speed handheld cleaning head to perform rapid laser scanning on the workpiece, with the advantages of good beam quality, uniform spot, and easy installation and movement.

Product Details

Laser cutter cleaner and welder

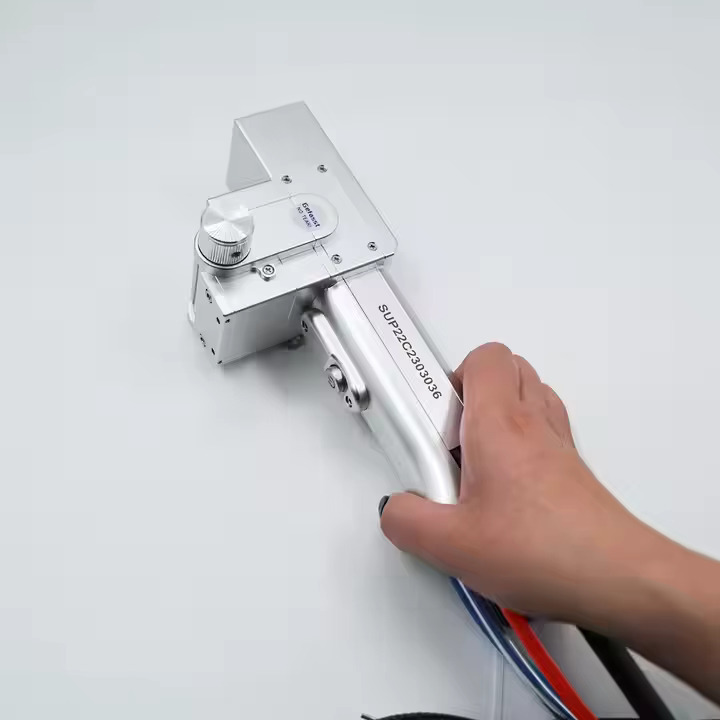

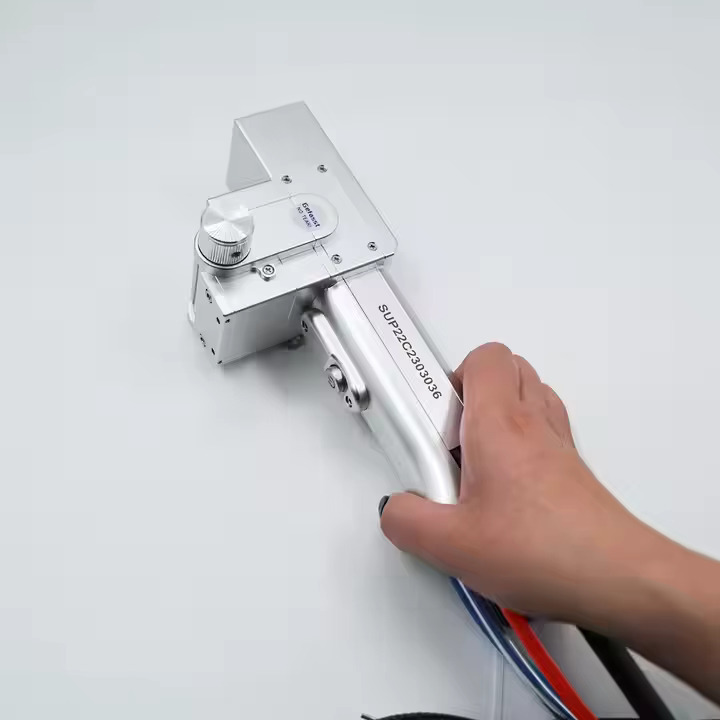

Lightweight shape, ergonomic design, comfortable grip, easy to operate, with safety alarm, automatic light lock after removing the workpiece, high safety.

Added timing function

The laser cleaning machine support customized timing function, when the machine is not in use, it can be rented for cleaning services to earn back the cost of the machine,Big profit and better protect the workpiece. Make the cleaning effect better.

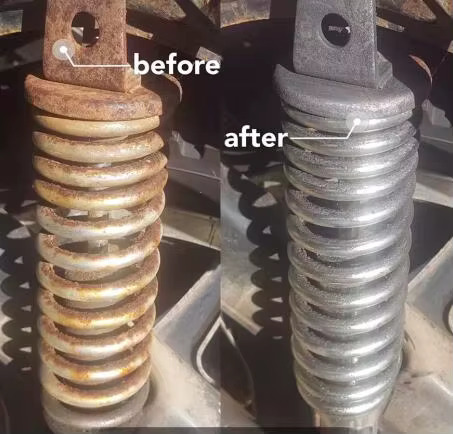

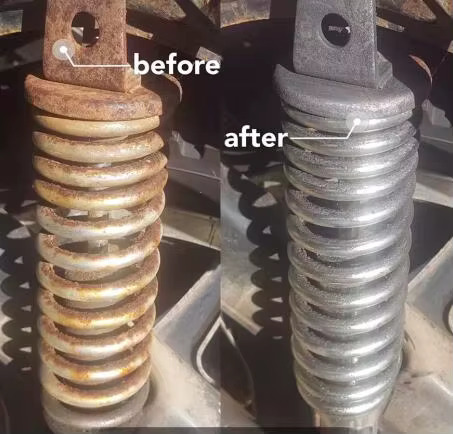

Removing large areas of rust from metal

Compared with traditional industrial cleaning methods, laser cleaning has many advantages. Laser cleaning is fast, the equipment is simple, and it can be customized and automated. In addition, laser cleaning can also achieve long-distance cleaning, non-contact cleaning, and large-area surface cleaning. Laser cleaning can clean many materials and has a wide range of applications.

1. Rust

Rust is a common contaminant on metal parts. Removing rust is not only essential for the aesthetics of the finished product, but also important as a pretreatment before welding, joining, painting or bonding processes. Unlike traditional methods, laser beam rust removal is fast and risk-free.

2. Varnish and Paint

Paint and varnish are difficult to remove. During metal fabrication, stripping off paint, varnish or powder coating can become a hassle. Laser energy can vibrate even thick and old paint coatings and remove them cleanly. Laser paint removal is easy and hassle-free. They can even remove epoxy coatings.

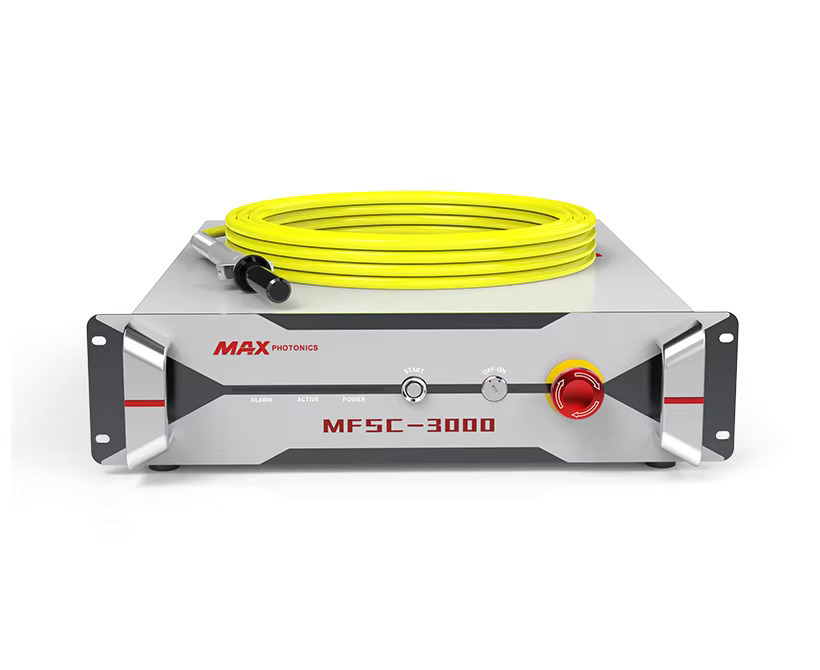

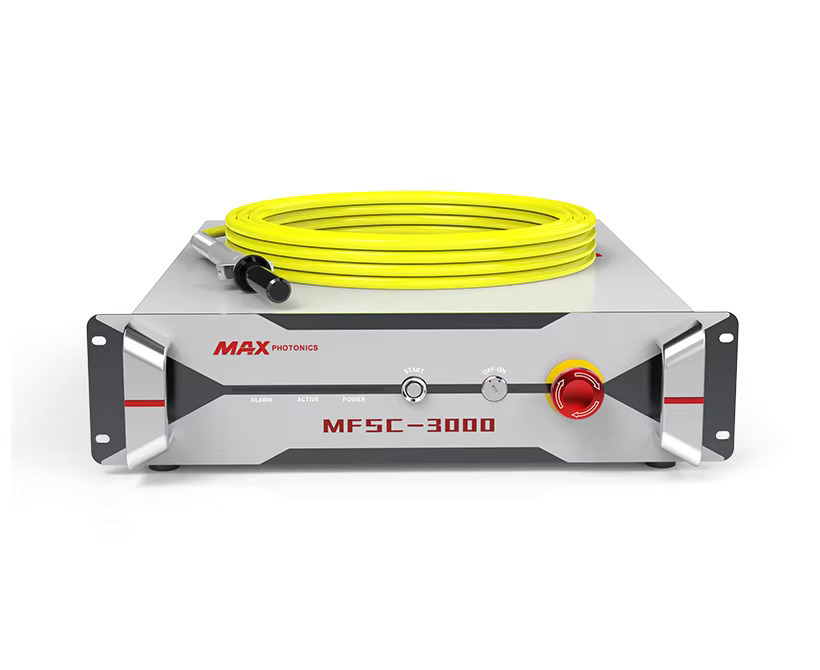

MAX 1500W 2000W 3000W Fiber Laser Source

The new generation of Single Module 1500W-3000W Fiber Lasers which combined with high power, compact size, superior beam quality, and high light conversion efficiency.

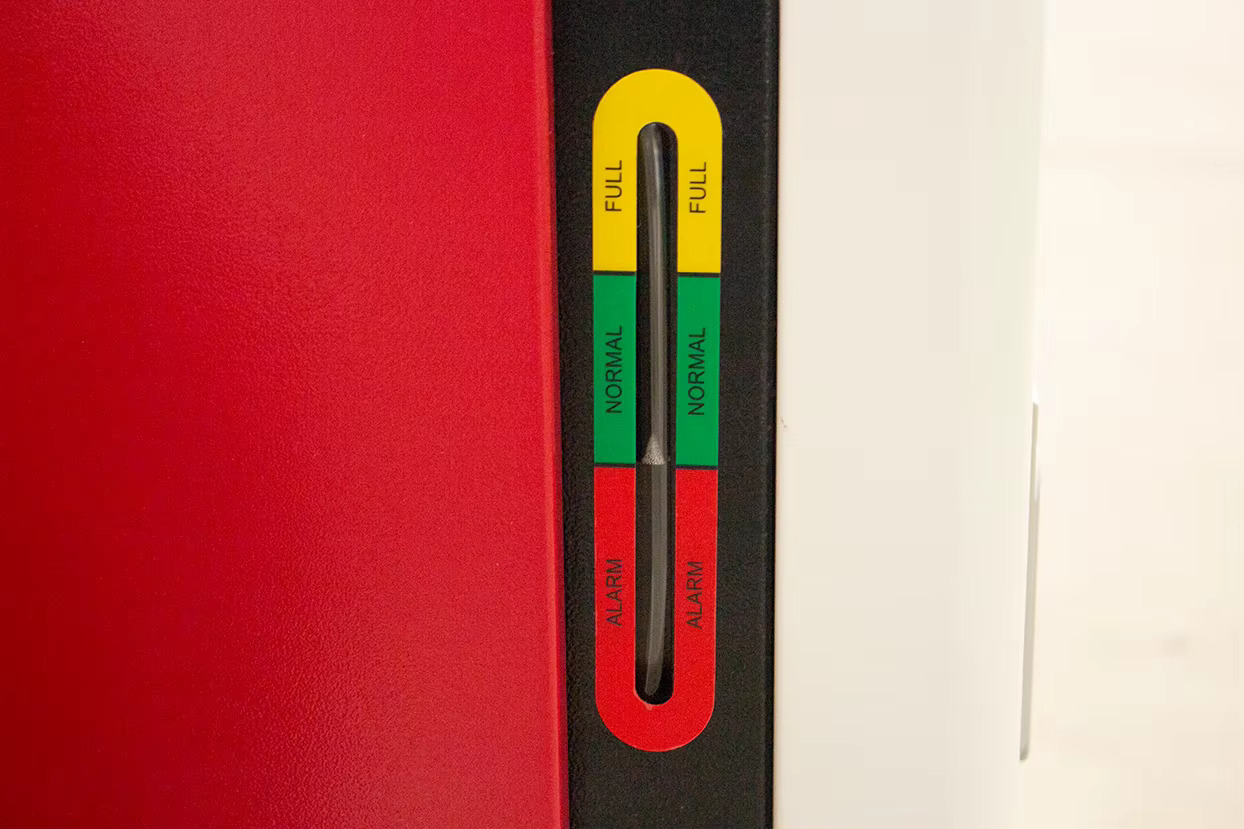

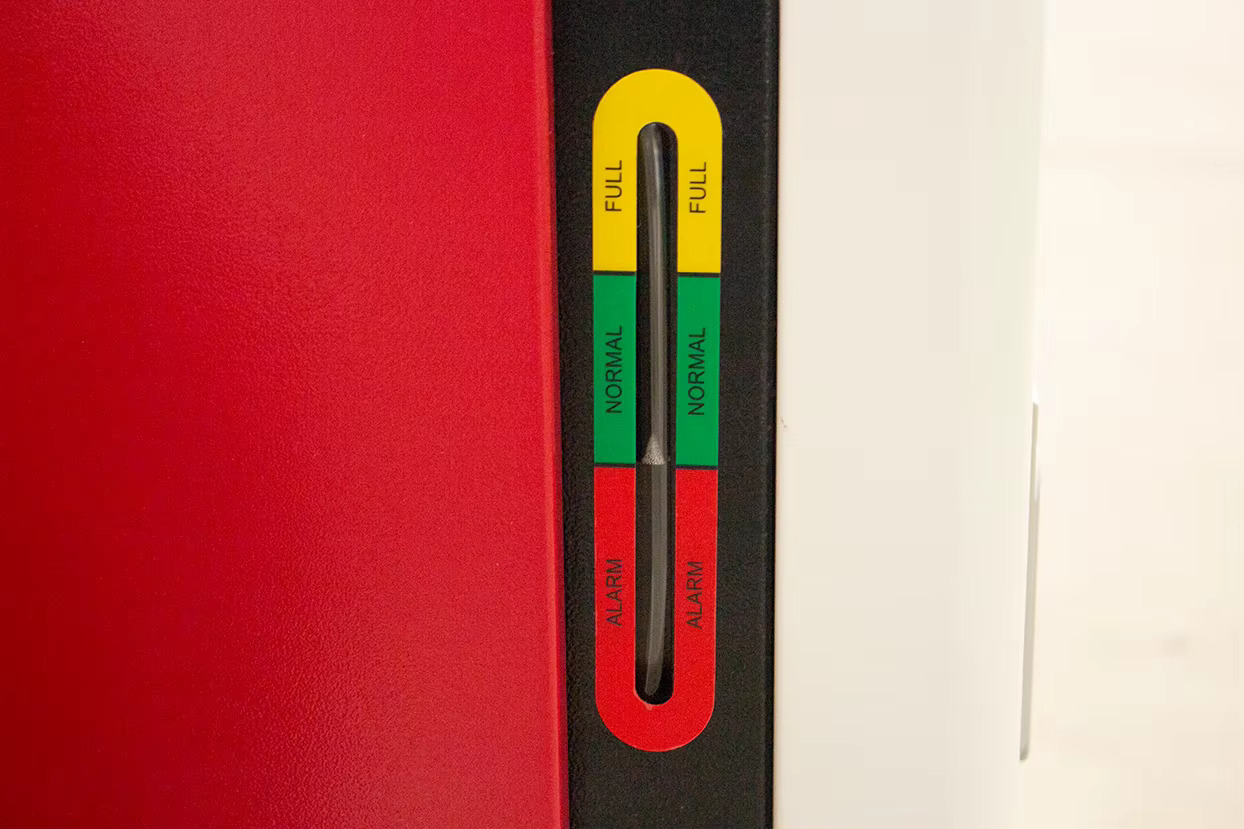

Industry Water Cooler

Fault alarm protection, the machine will automatically output fault signals when it fails Closed water tank or open water tank, add water for convenience (if the water volume is insufficient, the water level line will indicate or automatically alarm) Quick water addition, insert the bottled water into the filling port The unit is equipped with high and low pressure protection, compressor overload protection, flow protection, circuit board protection, fan overload protection, water pump protection

Product Parameters

Laser power

1500W/2000W/3000W

Usage

Rust removal; Paint removal)

Applicable Material

Stainless Steel, Carbon steel, Aluminum, Metal

Fiber Length

8~10 Meters

wavelength

1080nm

Cooling System

Water Cooling

Laser Head Brand

SupWeiye

Cooling Machine

Industry Water Chiller

Laser Source

JPT/ MAX/ RAYCUS

Welding Mode

Manual Handheld

Laser Gun Weight

1.2kg

Welding Speed Range

0~120 mm/s

Working environment temperature range

15~35 ℃

Application Scenarios

-

-

参数列表

- Brand: ZCLASER

- Model: 3 in 1 Fiber Laser Cleaning Machine

- Price: $2,590~$2,650

- Delivery period: 1 unit/10 days

- Warranty period: 2 years warranty for core components, 3 years warranty for the whole machine

-

Keywords:

Laser Welding Machine

laser

fiber

Laser Cleaning Machine

Laser Cutting Machine

Classification:

Product Description

Features

This product is mainly composed of laser source, handheld cleaning head, control panel, cabinet, etc. The cleaning system uses fiber laser, with fiber transmission, and after the fiber output is focused, it passes through a high-speed handheld cleaning head to perform rapid laser scanning on the workpiece, with the advantages of good beam quality, uniform spot, and easy installation and movement.

Product Details

Laser cutter cleaner and welder

Lightweight shape, ergonomic design, comfortable grip, easy to operate, with safety alarm, automatic light lock after removing the workpiece, high safety.

Added timing function

The laser cleaning machine support customized timing function, when the machine is not in use, it can be rented for cleaning services to earn back the cost of the machine,Big profit and better protect the workpiece. Make the cleaning effect better.

Removing large areas of rust from metal

Compared with traditional industrial cleaning methods, laser cleaning has many advantages. Laser cleaning is fast, the equipment is simple, and it can be customized and automated. In addition, laser cleaning can also achieve long-distance cleaning, non-contact cleaning, and large-area surface cleaning. Laser cleaning can clean many materials and has a wide range of applications.

1. Rust

Rust is a common contaminant on metal parts. Removing rust is not only essential for the aesthetics of the finished product, but also important as a pretreatment before welding, joining, painting or bonding processes. Unlike traditional methods, laser beam rust removal is fast and risk-free.

2. Varnish and Paint

Paint and varnish are difficult to remove. During metal fabrication, stripping off paint, varnish or powder coating can become a hassle. Laser energy can vibrate even thick and old paint coatings and remove them cleanly. Laser paint removal is easy and hassle-free. They can even remove epoxy coatings.

MAX 1500W 2000W 3000W Fiber Laser Source

The new generation of Single Module 1500W-3000W Fiber Lasers which combined with high power, compact size, superior beam quality, and high light conversion efficiency.

Industry Water Cooler

Fault alarm protection, the machine will automatically output fault signals when it fails Closed water tank or open water tank, add water for convenience (if the water volume is insufficient, the water level line will indicate or automatically alarm) Quick water addition, insert the bottled water into the filling port The unit is equipped with high and low pressure protection, compressor overload protection, flow protection, circuit board protection, fan overload protection, water pump protection

Product Parameters

Laser power | 1500W/2000W/3000W |

Usage | Rust removal; Paint removal) |

Applicable Material | Stainless Steel, Carbon steel, Aluminum, Metal |

Fiber Length | 8~10 Meters |

wavelength | 1080nm |

Cooling System | Water Cooling |

Laser Head Brand | SupWeiye |

Cooling Machine | Industry Water Chiller |

Laser Source | JPT/ MAX/ RAYCUS |

Welding Mode | Manual Handheld |

Laser Gun Weight | 1.2kg |

Welding Speed Range | 0~120 mm/s |

Working environment temperature range | 15~35 ℃ |

Application Scenarios

ZCLASER

Shandong Zhancheng Intelligent Manufacturing Co., Ltd is a professional research, development, production andsales of laser cutting marking equipment company, can be tailored for differententerprises of various non-standard laser equipment. Companies and many large well-known enterprises at home and abroad to establish long- term stability ofhe interactive relations of cooperation, forthe majority of users with the perfect laser processing solutions and thecorresponding supporting facilities, widelyused in auto parts, instrument, measuring tool cutting tool, electronic communications, aerospace, petrochemical, military products, medicine, food,packaging, and various metal and non-metal material marking.and is a leading enterprise in the laser industry.

Qualifications

If you are interested in this product, please complete the following information submitted to us, we will arrange experts to contact you as soon as possible!

Related Products

Related Products

Floor 16, Building A, Rongsheng Times International, Licheng District, Jinan City, Shandong Province,China