ZCLASER Multi-Function Robotic Arm Welding Machine

- 产品描述

- parameter

-

- Brand: ZCLASER

- Commodity name: ZCLASER Multi-Function Robotic Arm Welding Machine

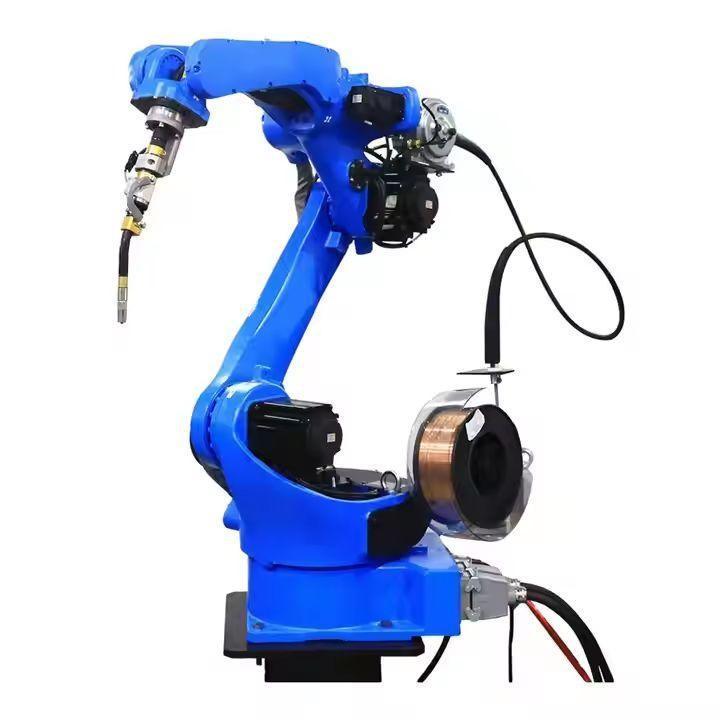

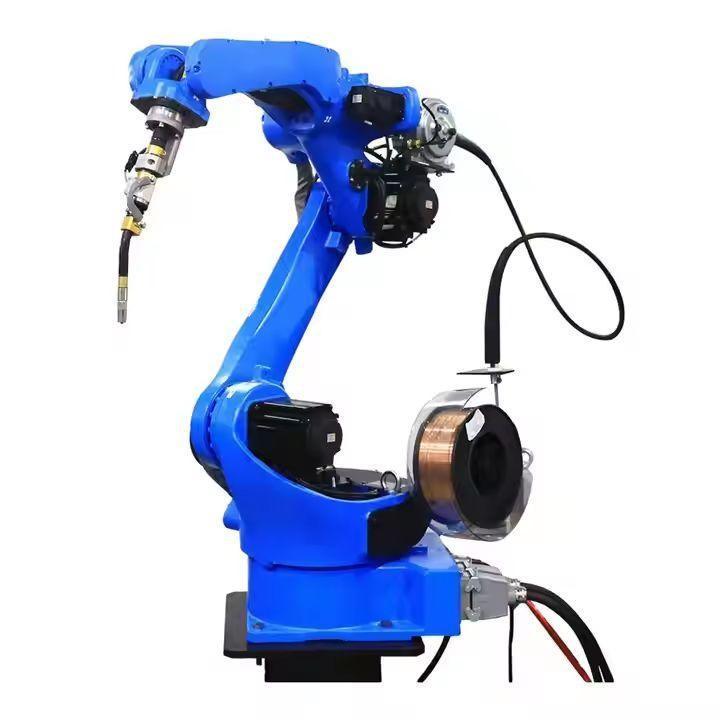

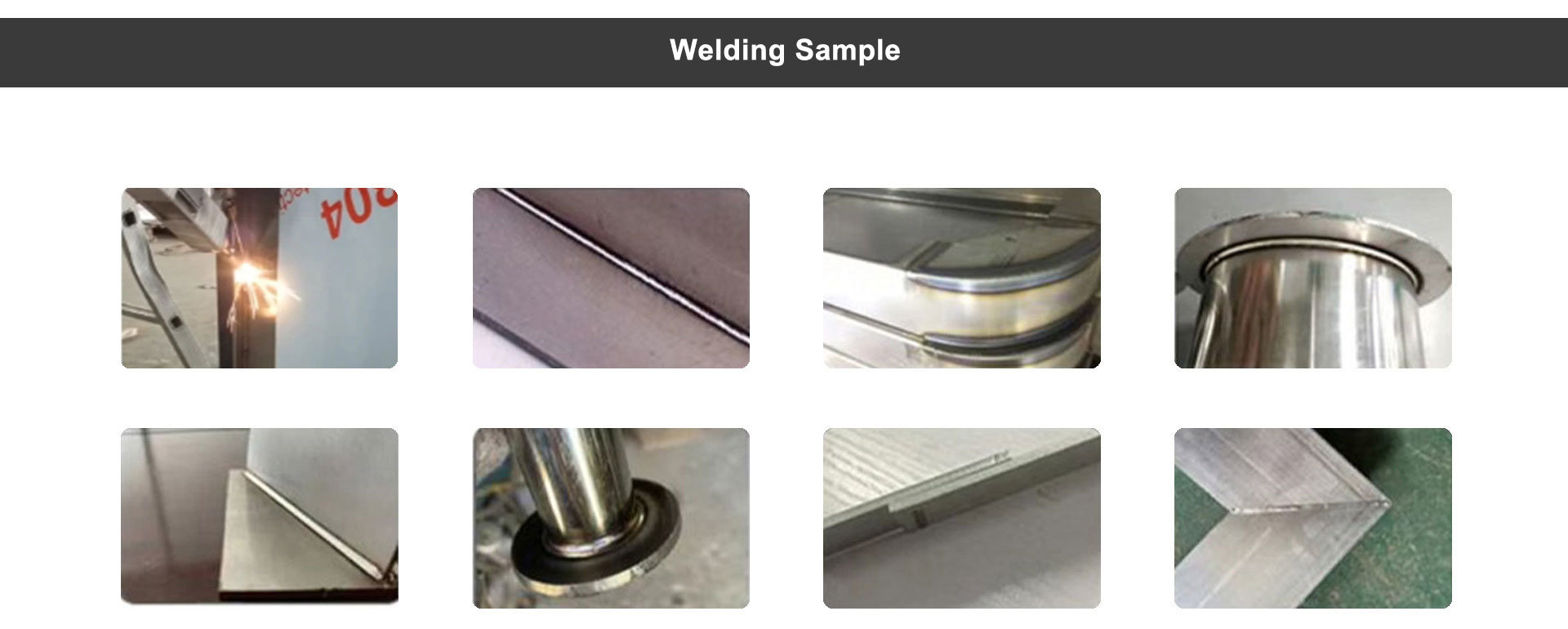

Combining robotic arm flexibility with laser welding precision, this device suits various metal materials. It features multi-axis movement, dual-mode welding/cutting switch, and intelligent control. With 1000-3000W power (customizable), it’s widely applied in automotive, aerospace, etc., ensuring efficient and precise welding.

What is the ZCLASER Multifunctional Laser Welding Robot Arm?

The ZCLASER Multifunctional Laser Welding Robot Arm is an advanced piece of industrial equipment designed to revolutionize metal welding processes. It combines the flexibility of a robotic arm with the precision of laser welding technology, enabling seamless and high-quality welds across a wide range of metal materials.

Here’s how it works:

Laser Source: At the heart of the robot arm is a high-powered laser source, specifically engineered for welding applications. This laser emits a concentrated beam of energy, capable of rapidly heating and fusing metal surfaces with pinpoint accuracy. The laser's adjustable power output allows for customization based on the thickness and type of metal being welded.

Robotic Arm Manipulation: The integrated robotic arm provides exceptional flexibility and mobility. With multiple axes of movement, it can reach complex angles and tight spaces, ensuring that even the most intricate welding tasks can be completed with ease. The arm's precise positioning system works in tandem with the laser to maintain consistent weld quality throughout the process.

Intelligent Control System: Equipped with a state-of-the-art control system, the laser welding robot arm offers intuitive operation and precise parameter adjustment. Operators can easily set and monitor variables such as welding speed, laser pulse frequency, and focus depth. The system also features real-time monitoring and feedback mechanisms, ensuring optimal performance and minimizing the risk of errors.

Features of The Machine

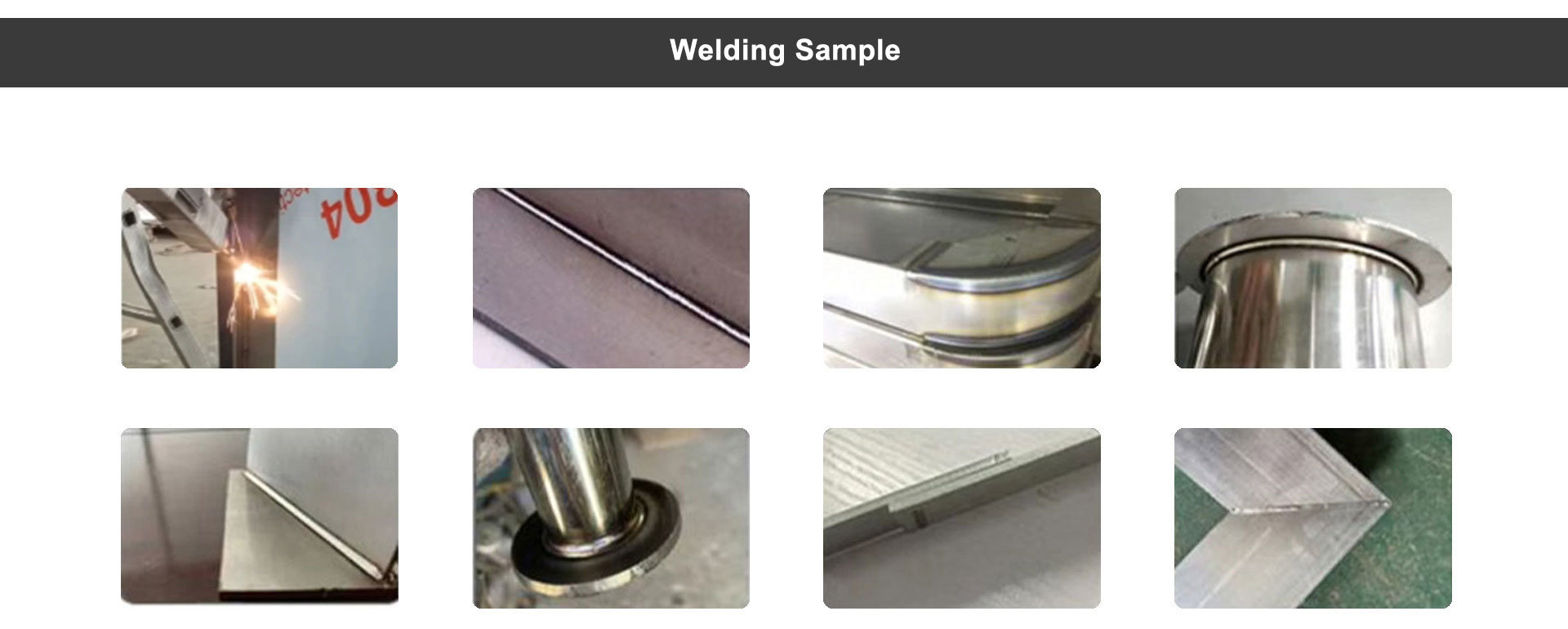

1. Precision:High-accuracy welding and cutting with minimal deformation.

2. Flexibility:Multi-axis arm handles complex tasks.

3. Dual-Mode:One-click switch between welding and cutting, adjustable parameters.

4. Automation:Boosts productivity, cuts errors and costs.

5. Versatility:Serves automotive, aerospace, electronics, etc.

We produce 1000w 1500w 2000w 3000w etc. We support customized machines.

Recommend: 1000 - 3000 W is suitable for welding various metal products, including automotive parts, appliance shells, and hardware tools. This power range ensures efficient welding speed for mass production and sufficient energy for proper melting depth, enhancing welding quality.

Control Board & Control Software

The international popular JCZ board and EZCAD oper ating software, easy to learn, accompanied by software manuals, to facilitate customer learning, supporting formats of PLT, AI, DXF, BMP, JPG, etc

Control card brand options: BSL, BJJCZ

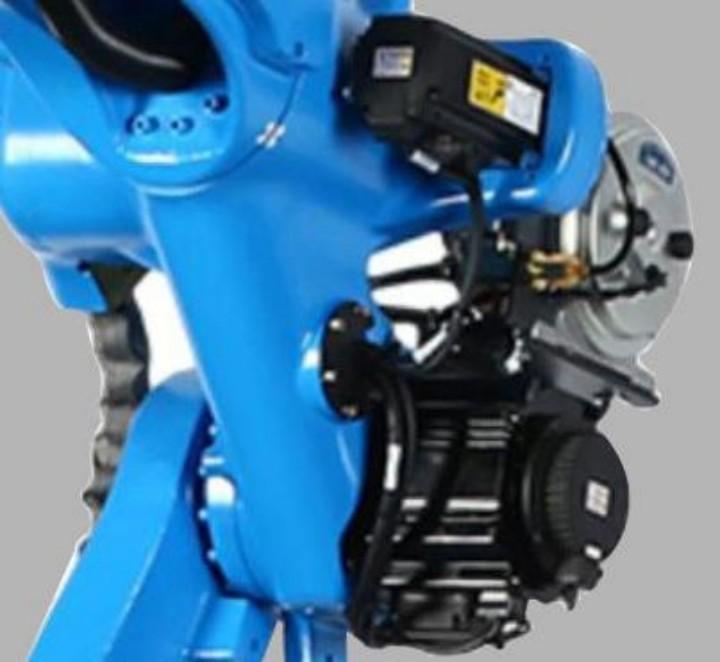

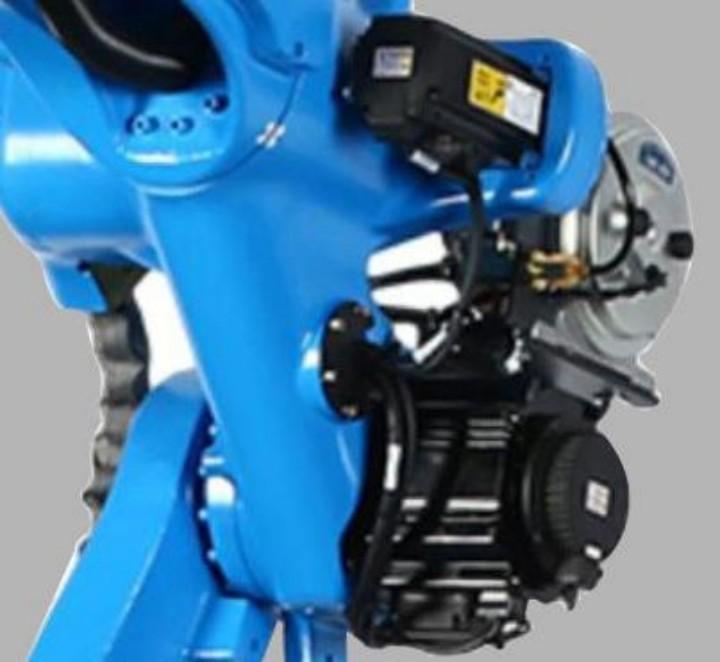

New contact pumpback arc

New contact pumpback arc starting Reduce arc splash and increase arc power.

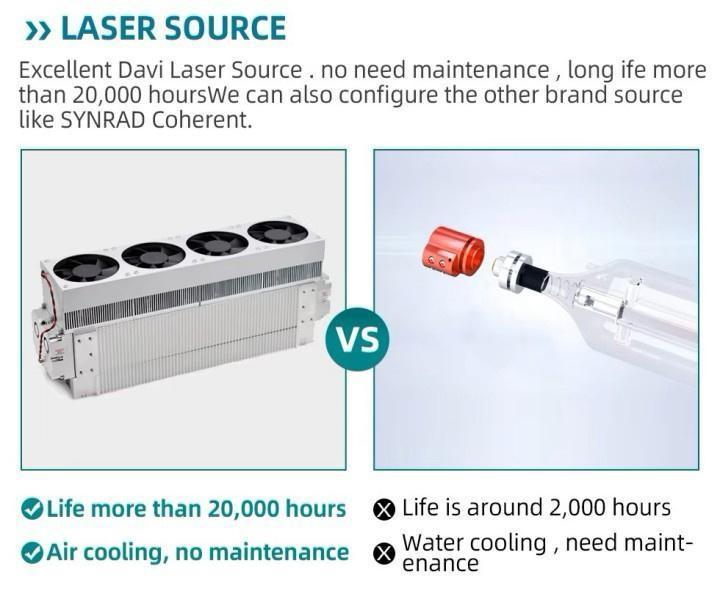

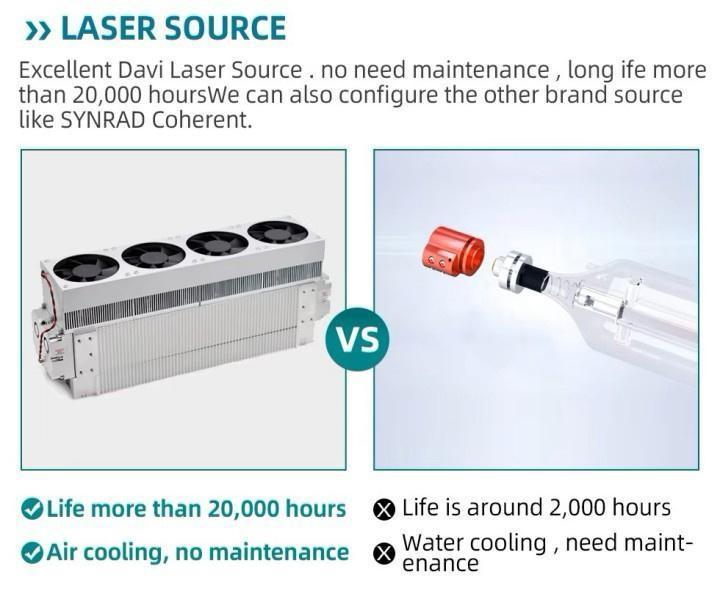

Laser source comparison

Material

Metal

Laser power

1000W/1500W/2000W/3000W Optional

dimensions

1440/1840/2000mm

welding source type

MIG, TIG, STICK

Maximum coverage

1454mm

weight (kg)

150

voltage

380V

Repeat Positioning Accuracy

±0.08mm

Installation method

Floor, ceiling, wall mounted

Installation temperature

0~45℃

relative humidity

20~80%(condensation-free)

IP rating

Wrist IP67, rest IP54

Type

Floor type/bracket type /Upside down type

Input / output signal

24VDC

-

-

参数列表

- Brand: ZC CNC LASER

- Model: CNC

- Price: 3300-3600$

- Delivery period: 30days

- Warranty period: Core components:2 years Other components:1 year

-

Keywords:

Industrial Robots Palletizer Machine Cobot Cobot Robot Arm

welding Robot Arm

new Industrial Robot

Classification:

Product Description

What is the ZCLASER Multifunctional Laser Welding Robot Arm?

The ZCLASER Multifunctional Laser Welding Robot Arm is an advanced piece of industrial equipment designed to revolutionize metal welding processes. It combines the flexibility of a robotic arm with the precision of laser welding technology, enabling seamless and high-quality welds across a wide range of metal materials.

Here’s how it works:

Laser Source: At the heart of the robot arm is a high-powered laser source, specifically engineered for welding applications. This laser emits a concentrated beam of energy, capable of rapidly heating and fusing metal surfaces with pinpoint accuracy. The laser's adjustable power output allows for customization based on the thickness and type of metal being welded.

Robotic Arm Manipulation: The integrated robotic arm provides exceptional flexibility and mobility. With multiple axes of movement, it can reach complex angles and tight spaces, ensuring that even the most intricate welding tasks can be completed with ease. The arm's precise positioning system works in tandem with the laser to maintain consistent weld quality throughout the process.

Intelligent Control System: Equipped with a state-of-the-art control system, the laser welding robot arm offers intuitive operation and precise parameter adjustment. Operators can easily set and monitor variables such as welding speed, laser pulse frequency, and focus depth. The system also features real-time monitoring and feedback mechanisms, ensuring optimal performance and minimizing the risk of errors.

Features of The Machine

1. Precision:High-accuracy welding and cutting with minimal deformation.

2. Flexibility:Multi-axis arm handles complex tasks.

3. Dual-Mode:One-click switch between welding and cutting, adjustable parameters.

4. Automation:Boosts productivity, cuts errors and costs.

5. Versatility:Serves automotive, aerospace, electronics, etc.

We produce 1000w 1500w 2000w 3000w etc. We support customized machines.

Recommend: 1000 - 3000 W is suitable for welding various metal products, including automotive parts, appliance shells, and hardware tools. This power range ensures efficient welding speed for mass production and sufficient energy for proper melting depth, enhancing welding quality.

Control Board & Control Software

The international popular JCZ board and EZCAD oper ating software, easy to learn, accompanied by software manuals, to facilitate customer learning, supporting formats of PLT, AI, DXF, BMP, JPG, etc

Control card brand options: BSL, BJJCZ

New contact pumpback arc

New contact pumpback arc starting Reduce arc splash and increase arc power.

Laser source comparison

Material | Metal |

Laser power | 1000W/1500W/2000W/3000W Optional |

dimensions | 1440/1840/2000mm |

welding source type | MIG, TIG, STICK |

Maximum coverage | 1454mm |

weight (kg) | 150 |

voltage | 380V |

Repeat Positioning Accuracy | ±0.08mm |

Installation method | Floor, ceiling, wall mounted |

Installation temperature | 0~45℃ |

relative humidity | 20~80%(condensation-free) |

IP rating | Wrist IP67, rest IP54 |

Type | Floor type/bracket type /Upside down type |

Input / output signal | 24VDC |

ZCLASER

Shandong Zhancheng Intelligent Manufacturing Co., Ltd is a professional research, development, production andsales of laser cutting marking equipment company, can be tailored for differententerprises of various non-standard laser equipment. Companies and many large well-known enterprises at home and abroad to establish long- term stability ofhe interactive relations of cooperation, forthe majority of users with the perfect laser processing solutions and thecorresponding supporting facilities, widelyused in auto parts, instrument, measuring tool cutting tool, electronic communications, aerospace, petrochemical, military products, medicine, food,packaging, and various metal and non-metal material marking.and is a leading enterprise in the laser industry.

Qualifications

If you are interested in this product, please complete the following information submitted to us, we will arrange experts to contact you as soon as possible!

Related Products

Related Products

Floor 16, Building A, Rongsheng Times International, Licheng District, Jinan City, Shandong Province,China