Many materials are used in people’s daily life. Among them, the application of leather can be said to be diverse. The more common ones are leather clothing, leather shoes, belts, watch straps, wallets, handicrafts, etc. The production process includes leather making, shoe making, and leather clothing. , Leather goods, fur and other main industries, as well as supporting industries such as leather chemicals, leather hardware, leather machinery, and accessories. Of course, good leather products must be decorated with exquisite patterns. In the past, leather patterns were printed using traditional craftsmanship, which inevitably caused some damage during the manufacturing process, and the efficiency of using traditional craftsmanship was low. If fine patterns were made, it would take longer.

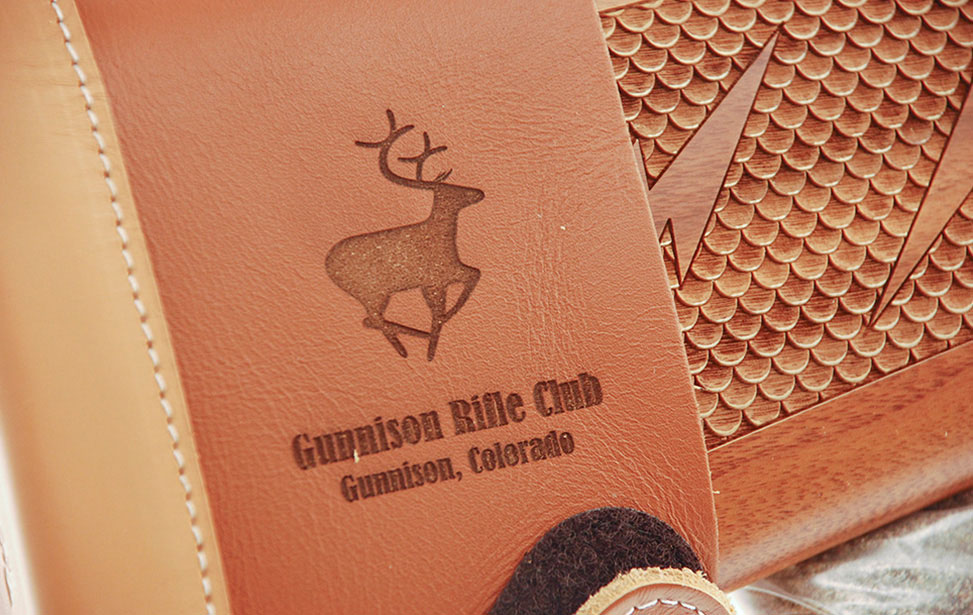

CO2 laser marking machine laser processing is a form of thermal processing. Because of the high-energy laser beam, it instantly completes the burning and engraving of the pattern on the surface of the leather. It is less affected by heat, so it can only be lasered and will not damage the leather to the leather. Any damage caused by the product, the engraving speed changes, and the effect is more accurate. All kinds of Chinese, English, numbers, dates, barcodes, QR codes, serial numbers, etc. are no problem. Some more complicated patterns can also be easily marked. demand. Let us take a look at what functions and features it has.

1. Use high-performance metal RF CO2 laser to enhance stability and laser life;

2. The high beam quality is good, the electro-optical conversion rate is high, and the processing speed is fast, which is 5-10 times that of the traditional laser marking machine;

3. No consumables, no maintenance, and long service life. Small size, suitable for working in harsh environments;

4. High reliability, maintenance-free, no chiller required, completely air-cooled, easy to operate;

5. Simple operation, equipped with humanized operating software;

6. Excellent optical quality, high precision, suitable for fine work, and suitable for most non-metallic materials;

Performance characteristics of CO2 laser marking machine

1. High marking accuracy, fast speed, free control of the depth of engraving

2. High laser power, suitable for engraving and cutting a variety of non-metal products

3. No consumables, low processing cost--The operating life of the laser is up to 20000-30000 hours

4. Clear marking, not easy to wear, high efficiency of engraving and cutting, environmental protection and energy saving

5. Use the 10.64um laser beam to expand, focus, and finally control the deflection of the galvanometer

6. Act on the surface of the workpiece according to the predetermined trajectory to vaporize the working surface to achieve the marking effect

7. Good beam pattern, stable system performance, rabbit maintenance, suitable for industrial processing sites with large batches, multiple varieties, high speed and high precision

continuous production

8. Very advanced optical path optimization design and unique graphics path optimization technology, coupled with the unique ultra-pulse function of the laser, make the cutting

speed faster.

Performance characteristics of CO2 laser marking machine

1. High marking accuracy, fast speed, free control of the depth of engraving

2. High laser power, suitable for engraving and cutting a variety of non-metal products

3. No consumables, low processing cost--The operating life of the laser is up to 20000-30000 hours

4. Clear marking, not easy to wear, high efficiency of engraving and cutting, environmental protection and energy saving

5. Use the 10.64um laser beam to expand, focus, and finally control the deflection of the galvanometer

6. Act on the surface of the workpiece according to the predetermined trajectory to vaporize the working surface to achieve the marking effect

7. Good beam pattern, stable system performance, rabbit maintenance, suitable for industrial processing sites with large batches, multiple varieties, high speed and high precision

continuous production

8. Very advanced optical path optimization design and unique graphics path optimization technology, coupled with the unique ultra-pulse function of the laser, make the cutting

speed faster.

Post time: May-28-2021