The marking technology of laser marking machine is applied more and more in the printing field, and the laser marking machine is used in plastics, metals, PCB chips, silicon chips, packaging and other materials. , Mechanical engraving, screen printing, chemical corrosion and other methods, with low cost, high volume, and can be controlled by a computer system, making drawings and marking the graphics and text you need, and the strength of the marking produced by the laser acting on the surface of the workpiece is permanent Sex is its outstanding feature.

At present, in the marking and printing industry, laser marking machines have occupied more than 90% of the market. The reason why laser marking machines have such a large share is because they have the following 8 advantages:

1. Permanent:

Laser marking machine marks will not fade due to environmental factors (touch, acid and reduced gas, high temperature, low temperature, etc.).

2. Anti-counterfeiting:

The mark engraved by laser marking machine technology is not easy to imitate and change, and it has strong anti-counterfeiting.

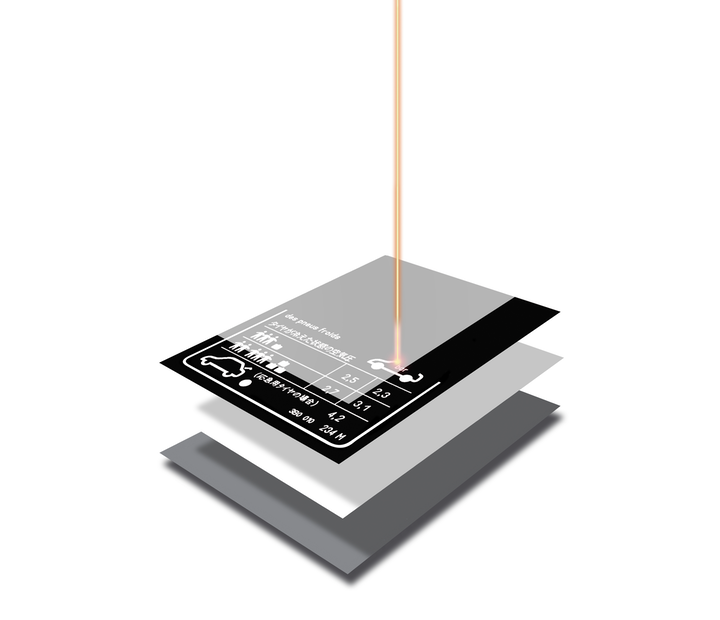

3. Non-contact:

Laser marking is processed by a non-mechanical “light knife”, which can print marks on any regular or irregular surface, and the workpiece will not generate internal stress after marking, ensuring the volume accuracy of the workpiece. No corrosion, no wear, no poison, no pollution to the working surface.

4. Wide applicability:

Laser marking machine can process a variety of metal and non-metal materials (aluminum, copper, iron, wood products, etc.).

Plastic Material

Metal Material

Glass Material

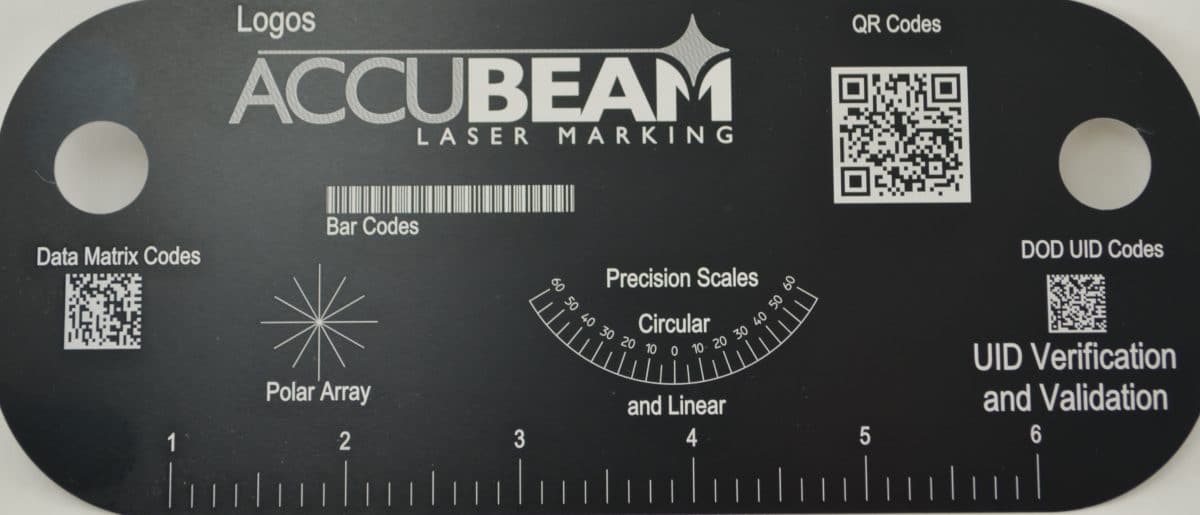

5. High engraving accuracy:

The articles engraved by the laser marking machine have fine patterns, and the minimum line width can reach 0.04mm. The marking is clear, durable and beautiful. Laser marking can meet the needs of printing large amounts of data on extremely small plastic parts.

6. Low operating cost:

The laser marking machine has fast marking speed and the marking is formed at one time, with low energy consumption and low operating cost.

7. High processing efficiency:

High processing efficiency and fast marking speed. The laser beam under computer control can move at a high speed (speed up to 5 to 7 meters per second), and the marking process can be completed within a few seconds.

8. Fast development speed:

Due to the combination of laser technology and computer technology, users can realize laser printing output as long as they program on the computer, and can change the printing design at any time, which fundamentally replaces the traditional mold making process, and provides for shortening the product upgrade cycle and flexible production. A convenient tool.

Post time: Apr-20-2021