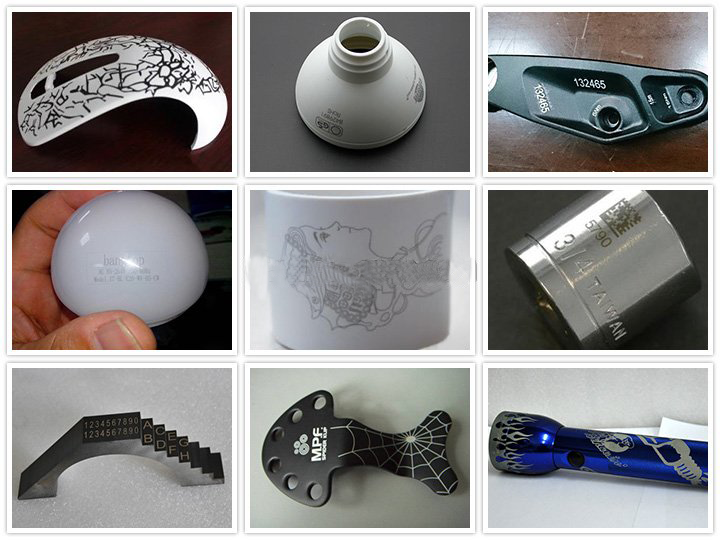

3D laser marking is a laser surface depression processing method. Compared with traditional 2D laser marking, 3D laser marking machine has greatly reduced the surface flatness requirements of the

processed object, and the processing effects are more colorful and more effective. Creative processing technology came into being. With the rapid development of laser technology, laser processing

forms are gradually changing. In order to meet the needs of curved surface processing, the current 3D laser marking technology is also gradually emerging.

Compared with 2D laser marking, the 3D laser marking machine can quickly mark uneven surfaces and irregular shapes by laser, which not only improves the processing efficiency, but also meets the

individual needs of current processing. In view of the current processing The production presents a rich style, and the material processing technology now provided is more innovative. In recent

years, as the market has gradually expanded the business needs of 3D labels, 3D laser marking technology is a concern of enterprises. Some domestic laser companies have developed their own 3D laser

marking machines. The development of 3D laser marking machines has been It is widely used in many industries to provide professional solutions for surface processing.

Compared with 2D laser marking, the 3D laser marking machine can quickly mark uneven surfaces and irregular shapes by laser, which not only improves the processing efficiency, but also meets the

individual needs of current processing. In view of the current processing The production presents a rich style, and the material processing technology now provided is more innovative. In recent

years, as the market has gradually expanded the business needs of 3D labels, 3D laser marking technology is a concern of enterprises. Some domestic laser companies have developed their own 3D laser

marking machines. The development of 3D laser marking machines has been It is widely used in many industries to provide professional solutions for surface processing.

3D marking adopts the front focusing optical mode, using larger X and Y axis deflection lenses, so it can allow the laser spot to be transmitted larger, the focusing accuracy is better, and the

energy effect is better; if the 3D marking is in the same way as the 2D marking When working with the same focus accuracy, the marking range can be larger. After using the 3D laser marking machine,

the marking of the cylinder within a certain arc can be completed at one time, which greatly improves the processing efficiency. Furthermore, in real life, the surface shape of many parts is irregular,

and the advantages of 3D marking will appear very obvious.

It has the characteristics of high marking accuracy, no need to touch the surface of the processed article, long-lasting marking and not easy to rub, high processing efficiency, anti-counterfeiting

, etc. It can engrave a variety of non-metallic materials. Used in clothing accessories, pharmaceutical packaging, wine packaging, architectural ceramics, beverage packaging, fabric cutting, rubber

products, shell nameplates, craft gifts, electronic components, leather and other industries.

Post time: Jun-01-2021